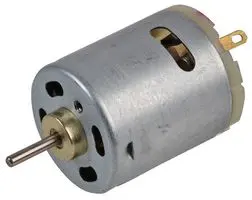

Product Description

Model Selection

ZD Leader has a wide range of micro motor production lines in the industry, including DC Motor, AC Motor, Brushless Motor, Planetary Gear Motor, Drum Motor, Planetary Gearbox, RV Reducer and Harmonic Gearbox etc. Through technical innovation and customization, we help you create outstanding application systems and provide flexible solutions for various industrial automation situations.

• Model Selection

Our professional sales representive and technical team will choose the right model and transmission solutions for your usage depend on your specific parameters.

• Drawing Request

If you need more product parameters, catalogues, CAD or 3D drawings, please contact us.

• On Your Need

We can modify standard products or customize them to meet your specific needs.

Product Parameters

Features:

1) Dimensions: 90mm

2) Power: 60, 90, 120W

3) Voltage(v): 12, 24, 90V

4) Speed(nS): 2500, 2600, 2800, 2900rpm

5) Reduction ratio: 3~ 200K

Usage:

Our dc gear motors can be widely used in medical appliance, packing mechanism, printing mechanism, cup making machine, textile machinery, and so on.

Certification: CE, UL, ISO9001 and Rohs

| Gearhead Model | Gear Ratio |

| 5GN *K | 3,3.6,5,6,7.5,9,12.5,15,18,25,30,36,50,60,75,90,100,120,150,180,200 |

| 5GN10XK(Decimal gearhead) | |

Other Related Products

Click here to find what you are looking for:

Company Profile

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial, Power Tools |

|---|---|

| Operating Speed: | Constant Speed |

| Structure and Working Principle: | Brush |

| Size: | 90mm |

| Power: | 60, 90, 120W |

| Voltage: | 12, 24, 90V |

| Customization: |

Available

|

|

|---|

What are the key differences between brushed and brushless DC motors?

Brushed and brushless DC motors are two distinct types of motors that differ in their construction, operation, and performance characteristics. Here’s a detailed explanation of the key differences between brushed and brushless DC motors:

1. Construction:

Brushed DC Motors: Brushed DC motors have a relatively simple construction. They consist of a rotor with armature windings and a commutator, and a stator with permanent magnets or electromagnets. The commutator and brushes make physical contact to provide electrical connections to the armature windings.

Brushless DC Motors: Brushless DC motors have a more complex construction. They typically consist of a stationary stator with permanent magnets or electromagnets and a rotor with multiple coils or windings. The rotor does not have a commutator or brushes.

2. Commutation:

Brushed DC Motors: In brushed DC motors, the commutator and brushes are responsible for the commutation process. The brushes make contact with different segments of the commutator, reversing the direction of the current through the armature windings as the rotor rotates. This switching of the current direction generates the necessary torque for motor rotation.

Brushless DC Motors: Brushless DC motors use electronic commutation instead of mechanical commutation. The commutation process is managed by an external electronic controller or driver. The controller determines the timing and sequence of energizing the stator windings based on the rotor position, allowing for precise control of motor operation.

3. Efficiency:

Brushed DC Motors: Brushed DC motors tend to have lower efficiency compared to brushless DC motors. This is primarily due to the energy losses associated with the brushes and commutation process. The friction and wear between the brushes and commutator result in additional power dissipation and reduce overall motor efficiency.

Brushless DC Motors: Brushless DC motors are known for their higher efficiency. Since they eliminate the use of brushes and commutators, there are fewer energy losses and lower frictional losses. The electronic commutation system allows for precise control of the motor’s operation, maximizing efficiency and reducing power consumption.

4. Maintenance:

Brushed DC Motors: Brushed DC motors require regular maintenance due to the wear and tear of the brushes and commutator. The brushes need periodic replacement, and the commutator requires cleaning to maintain proper electrical contact. The maintenance requirements contribute to additional costs and downtime for brushed DC motors.

Brushless DC Motors: Brushless DC motors have a relatively maintenance-free operation. As they do not have brushes or commutators, there is no need for brush replacement or commutator cleaning. This results in reduced maintenance costs and increased reliability of brushless DC motors.

5. Speed Control:

Brushed DC Motors: Brushed DC motors offer simpler speed control options. The speed can be controlled by adjusting the applied voltage or by varying the resistance in the armature circuit. This allows for relatively straightforward speed regulation.

Brushless DC Motors: Brushless DC motors provide more advanced and precise speed control capabilities. The speed can be controlled through the electronic commutation system by adjusting the timing and sequence of the stator windings’ energization. This allows for precise control of the motor’s speed and acceleration.

These key differences between brushed and brushless DC motors make each type suitable for different applications depending on factors such as efficiency requirements, maintenance considerations, and control complexity.

How do DC motors compare to AC motors in terms of performance and efficiency?

When comparing DC (Direct Current) motors and AC (Alternating Current) motors, several factors come into play, including performance and efficiency. Here’s a detailed explanation of how DC motors and AC motors compare in terms of performance and efficiency:

1. Performance:

Speed Control: DC motors typically offer better speed control compared to AC motors. DC motors can be easily controlled by varying the voltage applied to the armature, allowing for precise and smooth speed regulation. On the other hand, AC motors rely on complex control methods such as variable frequency drives (VFDs) to achieve speed control, which can be more challenging and costly.

Starting Torque: DC motors generally provide higher starting torque compared to AC motors. The presence of a separate field winding in DC motors allows for independent control of the field current, enabling higher torque during motor startup. AC motors, especially induction motors, typically have lower starting torque, requiring additional starting mechanisms or devices.

Reversibility: DC motors offer inherent reversibility, meaning they can easily change their rotational direction by reversing the polarity of the applied voltage. AC motors, particularly induction motors, require more complex control mechanisms to achieve reversible operation.

Dynamic Response: DC motors have faster dynamic response characteristics compared to AC motors. They can quickly accelerate or decelerate, making them suitable for applications that require rapid changes in speed or precise control, such as robotics or servo systems.

2. Efficiency:

Full Load Efficiency: AC motors, especially three-phase induction motors, generally exhibit higher full load efficiencies compared to DC motors. This efficiency advantage is primarily due to the absence of commutation and the use of a rotating magnetic field in AC motors, which results in reduced energy losses and improved efficiency.

Partial Load Efficiency: DC motors can have higher efficiency at partial loads compared to AC motors. DC motors can be controlled by adjusting the armature voltage, allowing them to operate at reduced power while maintaining relatively high efficiency. AC motors, especially induction motors, may experience reduced efficiency at partial loads due to factors such as increased iron losses and reduced power factor.

Regenerative Braking: DC motors offer the advantage of regenerative braking, where the motor acts as a generator and converts kinetic energy into electrical energy during deceleration or braking. This regenerative braking capability allows for energy recovery, increasing overall system efficiency. AC motors typically require additional components or systems to achieve regenerative braking.

Power Factor: AC motors, when properly designed and operated, can have a power factor close to unity. This means that they draw relatively low reactive power from the electrical grid, resulting in improved power system efficiency. DC motors, on the other hand, may exhibit a lower power factor and require power factor correction measures if necessary.

In summary, DC motors and AC motors have their respective strengths and weaknesses in terms of performance and efficiency. DC motors excel in speed control, starting torque, reversibility, and dynamic response. AC motors, particularly three-phase induction motors, generally offer higher full load efficiency and power factor. However, DC motors can achieve higher efficiency at partial loads and have the advantage of regenerative braking. The choice between DC motors and AC motors depends on the specific application requirements, cost considerations, and the desired balance between performance and efficiency.

Where can individuals find reliable resources for learning more about DC motors and their applications?

Individuals seeking reliable resources to learn more about DC (Direct Current) motors and their applications can explore various sources that provide comprehensive and accurate information. Here’s a detailed explanation of where individuals can find reliable resources for learning about DC motors:

1. Manufacturer Websites:

Many DC motor manufacturers have dedicated sections on their websites that provide detailed information about their products, including specifications, application notes, technical guides, and whitepapers. These resources offer valuable insights into the design, operation, and application considerations of DC motors. Examples of reputable DC motor manufacturers include Baldor, Maxon Motor, and Faulhaber.

2. Industry Associations and Organizations:

Industry associations and organizations related to electrical engineering, automation, and motor technology can be excellent sources of reliable information. Examples include the Institute of Electrical and Electronics Engineers (IEEE) and the American Society of Mechanical Engineers (ASME). These associations often provide access to technical publications, research papers, conferences, and educational resources related to DC motors and their applications.

3. Technical Books and Publications:

Technical books and publications authored by experts in the field of electrical engineering and motor technology can provide in-depth knowledge about DC motors. Books such as “Electric Motors and Drives: Fundamentals, Types, and Applications” by Austin Hughes and “Practical Electric Motor Handbook” by Irving Gottlieb are widely regarded as reliable resources for learning about DC motors and their applications.

4. Online Educational Platforms:

Online educational platforms offer a wealth of resources for learning about DC motors. Websites like Coursera, Udemy, and Khan Academy provide online courses, tutorials, and video lectures on electrical engineering, motor theory, and applications. These platforms often have courses specifically dedicated to DC motors, covering topics such as motor principles, control techniques, and practical applications.

5. Research Papers and Scientific Journals:

Research papers published in scientific journals and conference proceedings can provide detailed insights into the latest advancements and research findings related to DC motors. Platforms like IEEE Xplore, ScienceDirect, and Google Scholar can be used to search for scholarly articles on DC motors. These papers are authored by researchers and experts in the field and provide reliable and up-to-date information on various aspects of DC motor technology.

6. Online Forums and Communities:

Online forums and communities focused on electrical engineering, motor technology, and DIY projects can be valuable resources for learning about DC motors. Platforms like Reddit, Stack Exchange (Electrical Engineering section), and specialized motor forums provide opportunities to ask questions, engage in discussions, and learn from experienced individuals in the field. However, it’s important to verify information obtained from online forums as they may contain a mix of opinions and varying levels of expertise.

When accessing these resources, it’s essential to critically evaluate the information and cross-reference it with multiple sources to ensure accuracy and reliability. By utilizing a combination of manufacturer websites, industry associations, technical books, online educational platforms, research papers, and online communities, individuals can gain a comprehensive understanding of DC motors and their applications.

editor by CX 2024-02-16