Product Description

| BG 28ZYT DC Brushed Motor | |

| Environmental Conditions | -20ºC~50ºC |

| Insulation Clase | B |

| Protection class | IP44 |

| Noise | ≤65dB |

| Number of phases | Single |

| Lifespan | >1000h |

| Electrical Specifications | |||||||||

| Model | RATED LOAD | NO LOAD | STALL | ||||||

| Voltage | Power |

Speed |

Torque | Current | Speed | Current | Torque | Current | |

| V | W | rpm | N.m | A | rpm | A | N.m | A | |

| BG 28395-1 | 12 | 3.79 | 3800 | 0.01 | 0.47 | 4500 | 0.11 | 0.064 | 2.6 |

| BG 28395-2 | 24 | 7.73 | 5200 | 0.014 | 0.5 | 6000 | 0.11 | 0.097 | 2.72 |

| We can also customize products according to customer requirements . | |||||||||

| Planetary Gear Motor Technical Data-BG | ||||||||

| Ratio | 3.3 | 4.6 | 37.7 | 52.1 | 70 | 585 | 810 | 2911 |

| NO-load speed | 1363 | 978 | 119 | 86 | 64 | 8 | 5.5 | 2.3 |

| Rated speed(rpm) | 1151 | 826 | 100 | 73 | 64 | 6.5 | 4.5 | 1.9 |

| Rated torque | 0.571 | 0.041 | 0.32 | 0.44 | 0.52 | 2 | 2 | 2 |

Established in 1994, HangZhou BG Motor Factory is a professional manufacturer of brushless DC motors, brushed DC motors, planetary gear motors, worm gear motors, Universal motors and AC motors. We have a plant area of 6000 square meters, multiple patent certificates, and we have the independent design and development capabilities and strong technical force, with an annual output of more than 1 million units. Since the beginning of its establishment, BG motor has focused on the overall solution of motors. We manufacture and design motors, provide professional customized services, respond quickly to customer needs, and actively help customers to solve problems. Our motor products are exported to 20 countries, including the United States, Germany, Italy, the United Kingdom, Poland, Slovenia, Switzerland, Sweden, Singapore, South Korea etc.

Our founder, Mr. Sun, has more than 40 years of experience in motor technology, and our other engineers also have more than 15 years of experience, and 60% of our staff have more than 10 years of experience, and we can assure you that the quality of our motors is top notch.

The products cover AGV, underwater robots, robots, sewing machine industry, automobiles, medical equipment, automatic doors, lifting equipment, industrial equipment and have a wide range of applications.

We strive for CHINAMFG in the quality of each product, and we are only a small and sophisticated manufacturer.

Our vision: Drive the world CHINAMFG and make life better!

Q:1.What kind of motors can you provide?

A:At present, we mainly produce brushless DC motors, brush DC motors, AC motors, Universal Motors; the power of the motor is less than 5000W, and the diameter of the motor is not more than 200mm;

Q:2.Can you send me a price list?

A:For all of our motors, they are customized based on different requirements like lifetime, noise,voltage,and shaft etc. The price also varies according to annual quantity. So it’s really difficult for us to provide a price list. If you can share your detailed requirements and annual quantity, we’ll see what offer we can provide.

Q:3.Can l get some samples?

A:It depends. If only a few samples for personal use or replacement, I am afraid it’ll be difficult for us to provide because all of our motors are custom made and no stock available if there are no further needs. If just sample testing before the official order and our MOQ,price and other terms are acceptable,we’d love to provide samples.

Q4:Can you provide OEM or ODM service?

A:Yes,OEM and ODM are both available, we have the professional R&D dept which can provide professional solutions for you.

Q5:Can l visit your factory before we place an order?

A:welcome to visit our factory,wear every pleased if we have the chance to know each other more.

Q:6.What’s the lead time for a regular order?

A:For orders, the standard lead time is 15-20 days and this time can be shorter or longer based on the different model,period and quantity.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial, Household Appliances, Car, Power Tools, Robot Arm |

|---|---|

| Operating Speed: | Low Speed |

| Excitation Mode: | DC |

| Function: | Driving |

| Casing Protection: | Closed Type |

| Number of Poles: | Can Be Choosen |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What is a DC motor, and how does it differ from other types of electric motors?

A DC (Direct Current) motor is an electric motor that converts electrical energy into mechanical motion. It operates based on the principle of electromagnetic induction and the interaction between current-carrying conductors and magnetic fields. DC motors are widely used in various applications due to their simplicity, controllability, and versatility. Here’s a detailed explanation of what a DC motor is and how it differs from other types of electric motors:

1. Basic Operation:

In a DC motor, electrical energy is supplied to the motor’s armature through a DC power source, typically a battery or a rectified power supply. The armature consists of multiple coils or windings that are evenly spaced around the motor’s rotor. The rotor is a cylindrical core with a shaft that rotates when the motor is energized. When current flows through the armature windings, it creates a magnetic field that interacts with the fixed magnetic field produced by the motor’s stator. This interaction generates a torque, causing the rotor to rotate.

2. Commutation:

DC motors employ a commutator and brushes for the conversion of electrical energy and the rotation of the rotor. The commutator consists of a segmented cylindrical ring attached to the rotor shaft, and the brushes are stationary conductive contacts that make contact with the commutator segments. As the rotor spins, the brushes maintain contact with the commutator segments, periodically reversing the direction of the current flow in the armature windings. This reversal of current flow in the armature windings ensures continuous rotation of the rotor in the same direction.

3. Types of DC Motors:

DC motors can be classified into different types based on their construction and the method of field excitation. The two main types are:

- Brushed DC Motors: Brushed DC motors have a mechanical commutator and brushes to switch the current direction in the armature windings. These motors are relatively simple, cost-effective, and offer good torque characteristics. However, the commutator and brushes require regular maintenance and can generate electrical noise and brush wear debris.

- Brushless DC Motors (BLDC): Brushless DC motors, also known as electronically commutated motors (ECMs), use electronic circuits and sensors to control the current flow in the motor windings. They eliminate the need for brushes and commutators, resulting in reduced maintenance and improved reliability. BLDC motors offer higher efficiency, smoother operation, and better speed control compared to brushed DC motors.

4. Speed Control:

DC motors provide excellent speed control capabilities. By adjusting the voltage applied to the motor, the speed of the DC motor can be regulated. Lowering the voltage reduces the motor’s speed, while increasing the voltage increases the speed. This feature makes DC motors suitable for applications that require precise speed control, such as robotics, conveyor systems, and electric vehicles.

5. Advantages and Disadvantages:

DC motors have several advantages, including:

- Simple construction and easy maintenance (for brushed DC motors).

- High starting torque.

- Precise speed control.

- Good controllability over a wide range of loads.

However, DC motors also have some limitations, such as:

- Brushed DC motors require periodic maintenance and have limited brush life.

- Brushed DC motors can generate electrical noise.

- Brushless DC motors are often more expensive compared to brushed DC motors.

6. Differences from Other Electric Motors:

DC motors differ from other types of electric motors, such as AC (Alternating Current) motors, in several ways:

- Power Source: DC motors require a DC power source, while AC motors operate from an AC power supply.

- Speed Control: DC motors offer precise speed control by adjusting the applied voltage, whereas AC motors typically rely on frequency control for speed regulation.

- Construction: DC motors use a commutator and brushes (in brushed DC motors) or electronic commutation (in brushless DC motors), while AC motors do not require commutation.

- Starting Torque: DC motors typically provide higher starting torque compared to AC motors.

Overall, DC motors are versatile and widely used in various applications due to their controllability, speed regulation capabilities, and simplicity. The advancements inpower electronics and motor control technologies have further enhanced the performance and efficiency of DC motors, making them a popular choice in many industries.

Can you explain the concept of armature winding in a DC motor?

In a DC (Direct Current) motor, the armature winding is a crucial component that plays a significant role in the motor’s operation. It is responsible for producing the magnetic field that interacts with the stator’s magnetic field, resulting in the generation of torque and the rotation of the motor. Here’s a detailed explanation of the concept of armature winding in a DC motor:

The armature winding is a coil or set of coils made of insulated wire that is wound around the armature core, which is typically a laminated iron core. The armature winding is located on the rotor of the motor and is connected to the commutator. It carries the armature current, which is the current that flows through the winding to create the magnetic field. The armature winding is usually made of copper wire due to its excellent electrical conductivity.

When a current passes through the armature winding, it generates a magnetic field around the winding according to Ampere’s circuital law. The direction of the magnetic field is determined by the right-hand rule, where the thumb represents the direction of the current flow, and the curled fingers indicate the direction of the magnetic field.

The interaction between the magnetic field produced by the armature winding and the magnetic field produced by the stator’s permanent magnets or electromagnets creates a mechanical force, known as torque. This torque causes the rotor to rotate, converting electrical energy into mechanical motion.

The armature winding is designed in such a way that it produces a multipole magnetic field. The number of poles in the winding corresponds to the number of poles in the stator’s magnetic field. This ensures that the magnetic fields of the armature and stator are properly aligned for efficient torque generation.

The armature winding is connected to the commutator, which is a cylindrical ring with multiple segments that are insulated from each other. As the rotor spins, the brushes make physical contact with different segments of the commutator, effectively reversing the direction of the current in the armature winding. This reversal of current flow ensures that the torque generated in the armature winding is always in the same direction, enabling continuous rotation of the rotor.

The design and configuration of the armature winding, including the number of turns, wire gauge, and connection scheme, can influence the motor’s performance characteristics, such as torque, speed, and efficiency. Optimal winding design is crucial for achieving the desired motor performance in various applications.

In summary, the armature winding in a DC motor is responsible for producing the magnetic field that interacts with the stator’s magnetic field, resulting in the generation of torque and the rotation of the motor. It is a critical component that facilitates the conversion of electrical energy into mechanical motion.

How does the size and power rating of a DC motor affect its suitability for different tasks?

The size and power rating of a DC (Direct Current) motor play crucial roles in determining its suitability for different tasks and applications. The size and power rating directly impact the motor’s performance characteristics, including its torque output, speed range, efficiency, and overall capabilities. Here’s a detailed explanation of how the size and power rating of a DC motor affect its suitability for different tasks:

Size of DC Motor:

The size of a DC motor refers to its physical dimensions, including its diameter, length, and overall volume. The size of the motor influences its ability to fit into specific spaces or applications with space constraints. Here are some key considerations regarding the size of a DC motor:

1. Space Limitations: In applications where space is limited, such as small robotic systems or compact machinery, smaller-sized DC motors are preferred. These motors provide a more convenient and efficient integration into the overall system design.

2. Weight Constraints: Certain applications, such as drones or lightweight robots, may have strict weight limitations. Smaller-sized DC motors are generally lighter, making them more suitable for weight-sensitive tasks where minimizing the overall system weight is essential.

3. Cooling and Heat Dissipation: The size of a DC motor can impact its ability to dissipate heat generated during operation. Smaller-sized motors may have less surface area for heat dissipation, which can lead to increased operating temperatures. In contrast, larger-sized motors typically have better heat dissipation capabilities, allowing for sustained operation under heavy loads or in high-temperature environments.

Power Rating of DC Motor:

The power rating of a DC motor refers to the maximum power it can deliver or the power it consumes during operation. The power rating determines the motor’s capacity to perform work and influences its performance characteristics. Here are some key considerations regarding the power rating of a DC motor:

1. Torque Output: The power rating of a DC motor is directly related to its torque output. Higher power-rated motors generally provide higher torque, allowing them to handle more demanding tasks or applications that require greater force or load capacity. For example, heavy-duty industrial machinery or electric vehicles often require DC motors with higher power ratings to generate sufficient torque for their intended tasks.

2. Speed Range: The power rating of a DC motor affects its speed range capabilities. Motors with higher power ratings can typically achieve higher speeds, making them suitable for applications that require rapid or high-speed operation. On the other hand, lower power-rated motors may have limited speed ranges, making them more suitable for applications that require slower or controlled movements.

3. Efficiency: The power rating of a DC motor can impact its efficiency. Higher power-rated motors tend to have better efficiency, meaning they can convert a larger proportion of electrical input power into mechanical output power. Increased efficiency is desirable in applications where energy efficiency or battery life is a critical factor, such as electric vehicles or portable devices.

4. Overload Capability: The power rating of a DC motor determines its ability to handle overloads or sudden changes in load conditions. Motors with higher power ratings generally have a greater overload capacity, allowing them to handle temporary load spikes without stalling or overheating. This characteristic is crucial in applications where intermittent or varying loads are common.

Overall, the size and power rating of a DC motor are important factors in determining its suitability for different tasks. Smaller-sized motors are advantageous in space-constrained or weight-sensitive applications, while larger-sized motors offer better heat dissipation and can handle heavier loads. Higher power-rated motors provide greater torque, speed range, efficiency, and overload capability, making them suitable for more demanding tasks. It is crucial to carefully consider the specific requirements of the application and choose a DC motor size and power rating that aligns with those requirements to ensure optimal performance and reliability.

editor by CX 2024-02-24

China Good quality High Reduction Ratio DC Parallel Gear Motor for Welding Machine with Great quality

Item Description

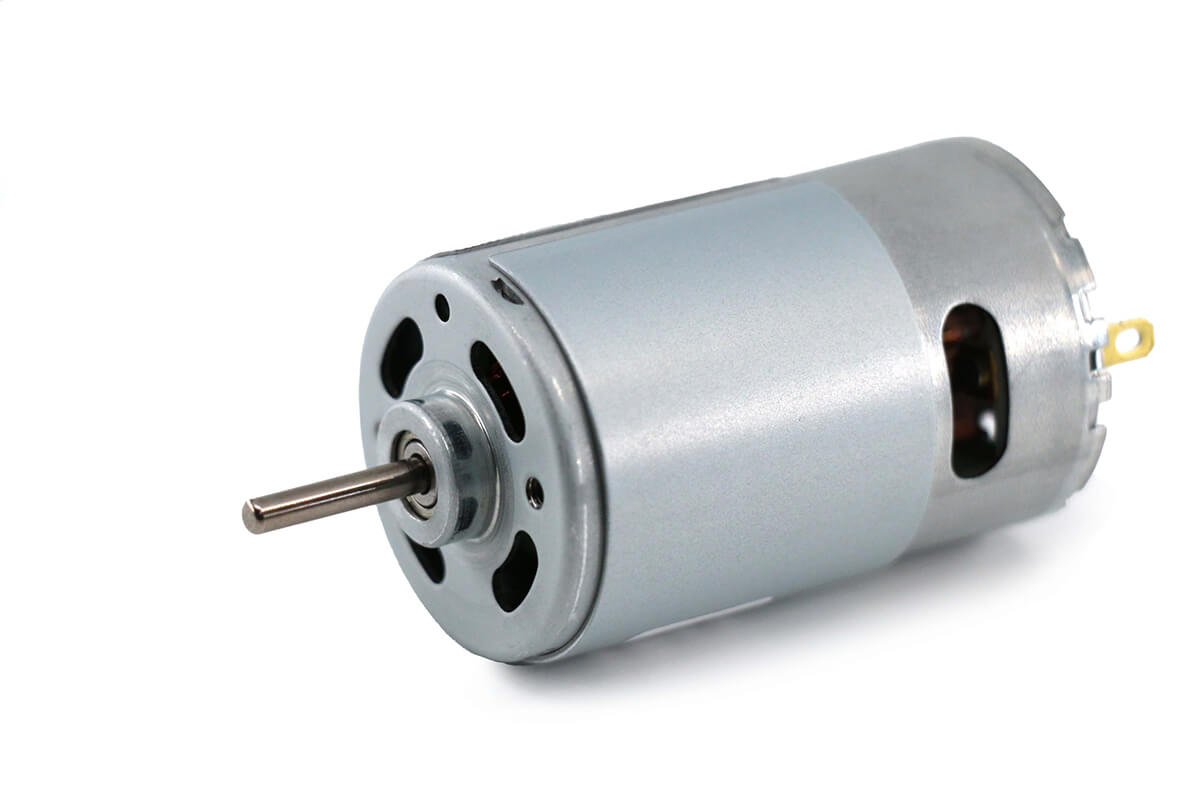

Product: RS-775

We can design and style it according to your particular specifications.

Gear box Info:

Motor knowledge:

2.Generation Flow

three.Company Info

In latest ten years, CZPT has been dedicated to the manufacture of the motor goods and the major goods can be labeled into the following collection, particularly DC motor, DC equipment motor, AC motor, AC gear motor, Stepper motor, Stepper gear motor, Servo motor and Linear actuator sequence.

Our motor goods are extensively applied in the fields of aerospace industry, automotive sector, fiscal products, house appliance, industrial automation and robotics, medical gear, office gear, packing CZPT and transmission business, providing consumers dependable customized answers for driving and controlling.

4.Our Services

1). Standard Provider:

two). Customization Support:

Motor specification(no-load speed , voltage, torque , diameter, sounds, life, testing) and shaft size can be tailor-produced according to customer’s requirements.

five.Deal & Shipping

How to Assemble a Planetary Motor

A Planetary Motor uses a number of planetary surfaces to make torque and rotational pace. The planetary technique allows for a vast assortment of equipment reductions. Planetary systems are especially effective in programs where greater torques and torque density are essential. As this kind of, they are a well-liked option for electric powered vehicles and other applications the place higher-velocity mobility is necessary. Even so, there are numerous benefits linked with employing a planetary motor. Go through on to find out far more about these motors.

VPLite

If you are looking to change the first VP, the VPLite has a equivalent output shaft as the original. This implies that you can blend and match your unique equipment sets, such as the enter and output shafts. You can even mix metallic inputs with plastic outputs. In addition, if you choose to change the gearbox, you can simply disassemble the entire device and replace it with a new a single with out getting rid of any output torque.

In comparison to a planetary motor, a spur gear motor uses much less gears and is for that reason less expensive to produce. However, the latter just isn’t suitable for large-torque programs. The torque created by a planetary gearmotor is evenly dispersed, which tends to make it perfect for applications that need higher torque. Nonetheless, you might have to compromise on the torque output if you might be seeking for a light-weight alternative.

The VersaPlanetary Lite gearbox replaces the aluminum ring equipment with a thirty% glass-loaded nylon gear. This gearbox is available in two measurements, which implies you can combine and match areas to get a much better equipment ratio. The VPLite gearbox also has a woman 5mm hex output shaft. You can blend and match distinct gearboxes and planetary gearboxes for greatest performance.

VersaPlanetary

The VersaPlanetary is a very versatile planetary motor that can be mounted in a selection of methods. Its exclusive design consists of a detachable shaft coupler program that can make it easy to swap out the motor with an additional. This planetary motor mounts in any situation in which a CIM motor mounts. Here’s how to assemble the motor. Very first, eliminate the hex output shaft from the VersaPlanetary output phase. Its one ring clip retains it in location. You can use a drill press to drill a gap into the output shaft.

Right after mounting the gearbox, you can then mount the motor. The mounting components integrated with the VersaPlanetary Planetary Motor comes with 4 10-32 threaded holes on a two-inch bolt circle. You can use these holes to mount your VersaPlanetary on a CIM motor or a CIM-compatible motor. When assembled, the VersaPlanetary gearbox has 72 different equipment ratios.

The VersaPlanetary gearbox is interchangeable with regular planetary gearboxes. Nevertheless, it does demand additional parts. You can buy a gearbox with no the motor but you’ll need a pinion. The pinion attaches to the shaft of the motor. The gearbox is really sturdy and durable, so you will not likely have to worry about it breaking or donning out.

Self-centering planetary gears

A planetary motor is a simple mechanical gadget that rotates all around a axis, with the planets shifting around the shaft in a radial course. The planets are positioned so that they mesh with the two the sun gear and the output gears. The provider forty eight is flexibly linked to the generate shaft and can move dependent on the forces exerted by the earth gears. In this way, the planets can usually be in the ideal mesh with the output gears and sunlight gear.

The initial phase in developing a planetary equipment motor is to identify the number of enamel in each planet. The number of teeth ought to be an integer. The tooth diameters of the planets must mesh with every other and the ring. Typically, the tooth of 1 planet should mesh with each other, but the spacing among them must be equivalent or higher than the other. This can be accomplished by considering the tooth depend of each and every planet, as properly as the spacing in between planets.

A second phase is to align the earth gears with the output gears. In a planetary motor, self-centering planetary gears must be aligned with each enter and output gears to give highest torque. For this to be possible, the planet gears must be related with the output shaft and the input shaft. Equally, the output shaft need to also be in a position to align with the enter gear.

Encoders

A planetary geared motor is a DC motor with a planetary gearbox. The motor can be utilised to generate weighty masses and has a ratio of 104:1. The shaft velocity is 116rpm when it is unloaded. A planetary gearbox has a lower backlash and is often used in purposes that need to have large torque. Planetary Motor encoders can assist you keep keep track of of your robot’s position or velocity.

They are also able to manage motor place and velocity with precision. Most of them attribute high resolution. A .18-degree resolution encoder will give you a minimum of 2000 transitions per rotation among outputs A and B. The encoder is built to industrial expectations and has a sturdy gearbox to keep away from injury. The encoder’s sturdy layout means it will not stall when the motor reaches its optimum pace.

There are a lot of benefits to a planetary motor encoder. A high-top quality a single will not lose its situation or pace even if it really is subject matter to shocks. A excellent quality planetary motor will also last a lengthy time. Planetary motors are excellent for resale or for your personal project. If you happen to be contemplating getting a planetary motor, think about this details. It’s going to aid you choose if a distinct product is right for your wants.

Expense

There are several advantages of planetary motors. 1 of the largest is their cost, but they can also be utilized in a lot of various apps. They can be mixed with a range of gearboxes, and are best for various kinds of robots, laboratory automation, and production programs. Planetary gearboxes are accessible in a lot of various resources, and plastic planetary gearboxes are an economical different. Plastic gearboxes decrease sounds at greater speeds, and metal input stage gears are obtainable for higher torques. A modified lubrication method can help with hard running situations.

In addition to getting far more durable, planetary motors are much far more successful. They use fewer gears, which lowers the general expense of manufacturing. Based on the application, a planetary motor can be used to transfer a large item, but is typically significantly less costly than its counterpart. It is a better option for conditions exactly where the load is relatively low and the motor is not used regularly. If you need a very higher torque output, a planetary motor may possibly be the better selection.

Planetary equipment models are a good selection for apps necessitating high precision, higher dynamics, and high torque density. They can be created and built making use of TwinCAT and TC Movement Designer, and are shipped as complete motor and gear device assemblies. In a few basic steps, you can compute the torque required and compare the expenses of diverse planetary gear units. You can then decide on the greatest product for your application. And because planetary gear models are so productive, they are a fantastic choice for higher-stop industrial apps.

Applications

There are numerous diverse applications of the planetary motor. 1 this kind of application is in motion management. Planetary gearboxes have many advantages, including substantial torque, lower backlash, and torsional stiffness. They also have an incredibly compact layout, and can be utilized for a variety of programs, from rack and pinion drives to delta robotics. In many cases, they are considerably less costly to manufacture and use than other varieties of motors.

One more application for planetary equipment models is in rotary tables. These machines need higher precision and low backlash for their specific positioning. Planetary gears are also required for sounds reduction, which is a common characteristic in rotary tables. Substantial precision planetary gears can make the height adjustment of OP tables a breeze. And due to the fact they are really tough and call for reduced noise, they are a excellent option for this application. In this case, the planetary gear is matched with an AM8000 series servomotor, which gives a broad assortment of selections.

The planetary gear transmission is also extensively employed in helicopters, cars, and marine programs. It is a lot more advanced than a countershaft generate, and is capable of increased torque to weight ratios. Other rewards consist of its compact layout and reduced noise. A essential concern in the improvement of this kind of transmission is to minimize vibration. If the output of a planetary gear transmission system is loud, the vibration induced by this sort of generate method may be also loud for comfort.