Product Description

Specification

I , Function

Micro intellectual control — One button to control open, stop and close.The light is on while opening or closing the door,three minutes later the light is off automatically. The unit running is controlled by computer program. Test the force of open or close the door, the optional function is photo beam, auto-close, lock door, etc. The door pauses momentarily then rebounds when it reaches the hinders on the closing way. The protecting functions are overload, over hot or low power input, etc.

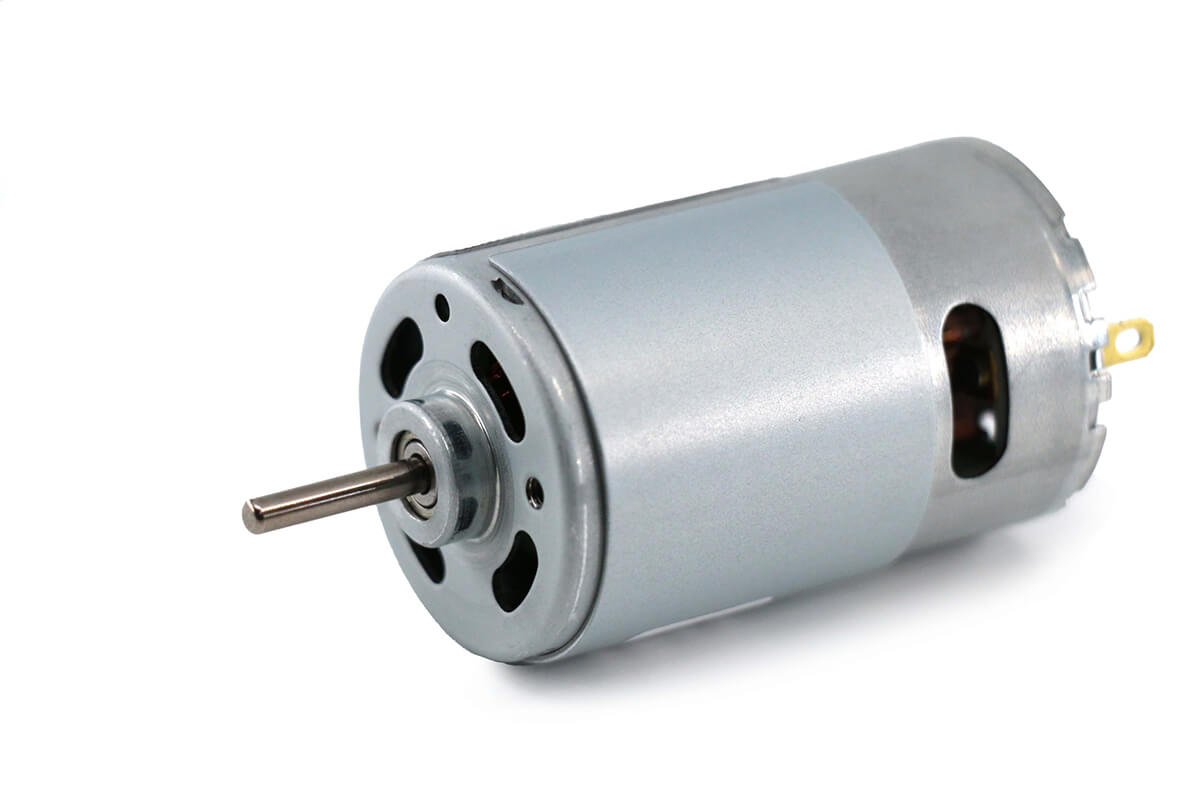

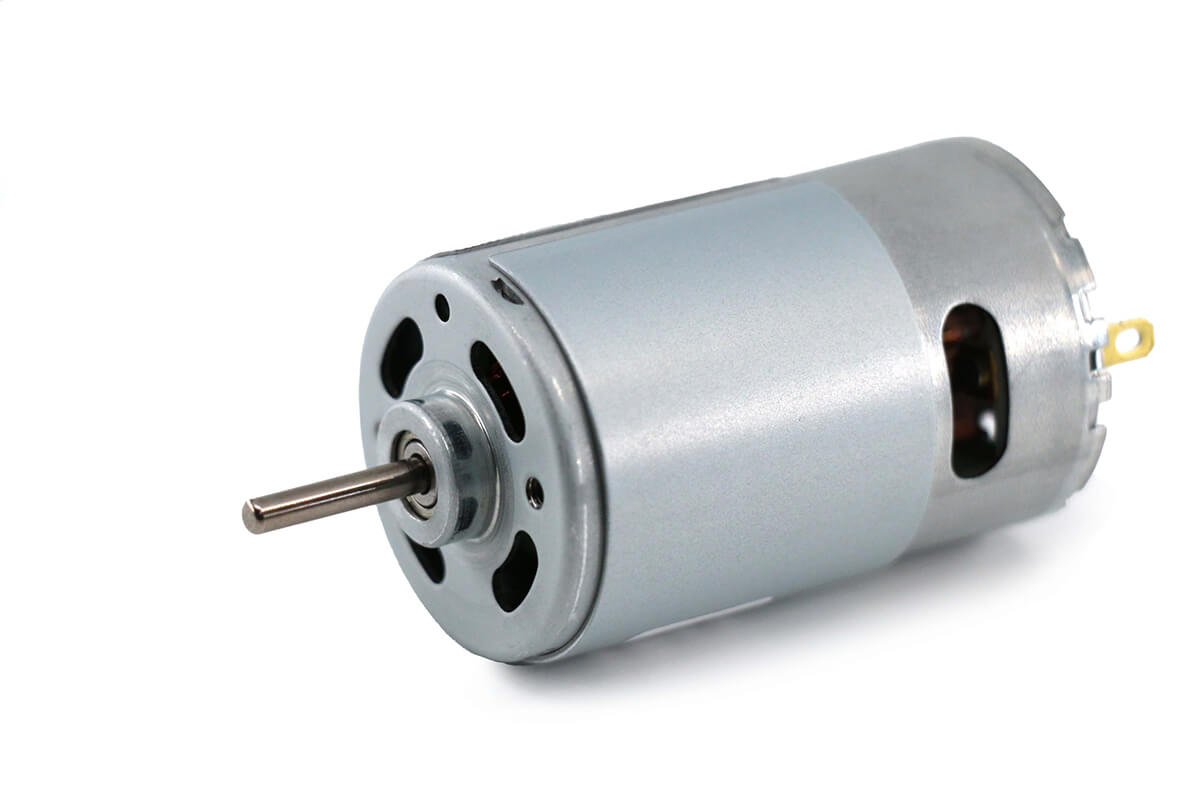

DC motor — Low noise, soft start, slow stopping to protect the unit and make sure it can be used for a long time.

LED display — Working situation can be shown on the LED screen.

Decoding — Rolling code.

Manual Disengagement– Open and close the door by hand without power.

Optional Functions– Photo beam, battery backup and wall button.

II,Technical parameters

Our ExhibitionCompany profilePackaging And LogisticsFAQ

1. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Transmitter,Tubular Motor Receiver,Sliding Gate Opener,Garage Door Opener,Photocell

3. Why should you buy from us not from other suppliers?

Hiland is professional designer and qualified manufacturer of the automatic door control systems.We have 15 years experience We

have sliding/garage/swing/rolling shutter opener and control systems,transmitters,receivers,photocell,flash lamp,keypad etc.

Q4.How can i get a price of needed garage door opener?

A: Please give the exactly size and quantity of your required door. We can give you a detail quotation based on your requirements.

Q5.We want to be your agent of our area. How to apply for this?

A: Please send your ideal and your profile to any e-mails of us .Let’s talk more. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Structure: | Straight Arm |

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

In which applications are DC motors commonly used, and what advantages do they offer?

DC (Direct Current) motors are widely used in various applications due to their versatility, controllability, and specific advantages they offer. Here’s a detailed explanation of the common applications of DC motors and the advantages they provide:

1. Robotics:

DC motors are extensively used in robotics for precise control of movement and manipulation. They provide high torque and speed control, allowing robots to perform tasks with accuracy and efficiency. DC motors enable robotic arms, grippers, and mobile robots to execute complex motions and interact with their environment effectively.

2. Industrial Automation:

In industrial automation, DC motors are employed in conveyors, actuators, and positioning systems. The ability to control the motor speed and torque makes them suitable for applications such as material handling, assembly lines, and CNC machines. DC motors offer precise control over acceleration, deceleration, and positioning, enhancing overall productivity and efficiency in manufacturing processes.

3. Electric Vehicles:

DC motors have been widely used in electric vehicles (EVs) for many years. They are commonly found in electric cars, motorcycles, and scooters. DC motors provide high torque from standstill, enabling efficient acceleration and smooth operation. They also offer regenerative braking capabilities, which help in energy recovery during deceleration, thereby increasing the vehicle’s overall efficiency.

4. Appliances:

DC motors are utilized in various household appliances, including fans, blenders, vacuum cleaners, and refrigerators. Their controllable speed and torque allow for efficient operation and improved energy consumption. In appliances where variable speed control is required, such as ceiling fans or blender settings, DC motors offer precise adjustment options to meet different user preferences.

5. Renewable Energy Systems:

DC motors play a crucial role in renewable energy systems, such as wind turbines and solar tracking systems. They convert the rotational energy from wind or sunlight into electrical energy. DC motors enable precise tracking of the sun’s movement for optimal solar energy collection and efficient conversion of wind energy into electricity.

6. Advantages of DC Motors:

DC motors offer several advantages that make them suitable for various applications:

- Precise Speed Control: DC motors provide accurate and adjustable speed control, allowing for precise regulation of motor output.

- High Starting Torque: DC motors deliver high torque at startup, making them suitable for applications requiring quick acceleration or heavy loads.

- Controllability: DC motors can be easily controlled using voltage regulation, current limiting, and feedback control techniques.

- Efficiency: DC motors have high efficiency, especially when operating at lower speeds.

- Reliability: DC motors are known for their robustness and reliability, requiring minimal maintenance.

- Compact Size: DC motors are available in various sizes and can be designed compactly, making them suitable for applications with space constraints.

These advantages make DC motors an attractive choice in various industries and applications where precise control, high starting torque, and reliability are essential.

Can DC motors be used in renewable energy systems, such as wind turbines or solar tracking systems?

Yes, DC (Direct Current) motors can be effectively used in various renewable energy systems, including wind turbines and solar tracking systems. The unique characteristics and advantages of DC motors make them well-suited for these applications. Here’s a detailed explanation of how DC motors can be utilized in renewable energy systems:

1. Wind Turbines:

DC motors can be employed in wind turbines to convert the mechanical energy of the wind into electrical energy. There are two common configurations:

a. Direct Drive Wind Turbines:

In direct drive wind turbines, the rotor of the turbine is directly connected to a DC generator. The rotor’s rotational motion is transmitted directly to the generator, which produces DC electrical power. DC motors can be used as DC generators in this configuration. The advantage of using DC motors/generators is their simplicity, reliability, and ability to operate efficiently at variable speeds, which is beneficial in varying wind conditions.

b. Hybrid Wind Turbines:

Hybrid wind turbines combine both aerodynamic and electrical conversion systems. In this configuration, DC motors can be utilized for the pitch control mechanism and yaw control system. The pitch control mechanism adjusts the angle of the turbine blades to optimize performance, while the yaw control system enables the turbine to align itself with the wind direction. DC motors provide precise control and responsiveness required for these functions.

2. Solar Tracking Systems:

DC motors are commonly employed in solar tracking systems to maximize the efficiency of solar panels by optimizing their orientation towards the sun. There are two main types of solar tracking systems:

a. Single-Axis Solar Tracking Systems:

Single-axis solar tracking systems adjust the inclination of solar panels along a single axis (typically the east-west axis) to track the movement of the sun throughout the day. DC motors can be used to drive the rotation mechanism that adjusts the panel’s tilt angle. By continuously adjusting the panel’s position to face the sun directly, the solar energy harvested can be significantly increased, resulting in higher energy output compared to fixed solar panel installations.

b. Dual-Axis Solar Tracking Systems:

Dual-axis solar tracking systems adjust the inclination of solar panels along both the east-west and north-south axes to track the sun’s movement throughout the day and throughout the year. DC motors are utilized in the rotation mechanisms for both axes. This type of solar tracking system provides the highest possible energy yield by keeping the solar panels perpendicular to the sun’s rays at all times, maximizing the exposure to sunlight.

DC motors are preferred in renewable energy systems due to their advantages, including:

- Efficiency at Variable Speeds: DC motors can operate efficiently at varying speeds, making them suitable for applications with fluctuating wind speeds or changing solar angles.

- Control and Precision: DC motors offer precise control and responsiveness, allowing for accurate tracking and adjustment in wind turbines and solar tracking systems.

- Reliability: DC motors are known for their reliability, with fewer moving parts compared to other motor types, reducing the risk of failure in remote or harsh environments.

- Compatibility with Energy Storage Systems: DC motors can easily be integrated with energy storage systems, such as batteries or supercapacitors, to store excess electrical energy generated by wind turbines or solar panels.

In conclusion, DC motors can be effectively utilized in renewable energy systems such as wind turbines and solar tracking systems. Their efficiency, control capabilities, reliability, and compatibility with energy storage systems make them a suitable choice for these applications, contributing to the advancement of sustainable energy generation.

Can DC motors be used in robotics, and if so, what are some notable applications?

Yes, DC (Direct Current) motors can be used in robotics, and they are widely employed in various robotic applications. DC motors offer several advantages that make them suitable for robotic systems, including their controllability, compact size, and versatility. Here’s a detailed explanation of how DC motors are used in robotics and some notable applications:

DC Motors in Robotics:

DC motors are commonly used in robotics due to their ability to provide precise speed control and torque output. They can be easily controlled by adjusting the voltage applied to the motor, allowing for accurate and responsive motion control in robotic systems. Additionally, DC motors can be designed in compact sizes, making them suitable for applications with limited space and weight constraints.

There are two main types of DC motors used in robotics:

- DC Brushed Motors: These motors have a commutator and carbon brushes that provide the electrical connection to the rotating armature. They are relatively simple in design and cost-effective. However, they may require maintenance due to brush wear.

- DC Brushless Motors: These motors use electronic commutation instead of brushes, resulting in improved reliability and reduced maintenance requirements. They are often more efficient and offer higher power density compared to brushed motors.

Notable Applications of DC Motors in Robotics:

DC motors find applications in various robotic systems across different industries. Here are some notable examples:

1. Robotic Manipulators: DC motors are commonly used in robotic arms and manipulators to control the movement of joints and end-effectors. They provide precise control over position, speed, and torque, allowing robots to perform tasks such as pick-and-place operations, assembly, and material handling in industrial automation, manufacturing, and logistics.

2. Mobile Robots: DC motors are extensively utilized in mobile robots, including autonomous vehicles, drones, and rovers. They power the wheels or propellers, enabling the robot to navigate and move in different environments. DC motors with high torque output are particularly useful for off-road or rugged terrain applications.

3. Humanoid Robots: DC motors play a critical role in humanoid robots, which aim to replicate human-like movements and capabilities. They are employed in various joints, including those of the head, arms, legs, and hands, allowing humanoid robots to perform complex movements and tasks such as walking, grasping objects, and facial expressions.

4. Robotic Exoskeletons: DC motors are used in robotic exoskeletons, which are wearable devices designed to enhance human strength and mobility. They provide the necessary actuation and power for assisting or augmenting human movements, such as walking, lifting heavy objects, and rehabilitation purposes.

5. Educational Robotics: DC motors are popular in educational robotics platforms and kits, including those used in schools, universities, and hobbyist projects. They provide a cost-effective and accessible way for students and enthusiasts to learn about robotics, programming, and control systems.

6. Precision Robotics: DC motors with high-precision control are employed in applications that require precise positioning and motion control, such as robotic surgery systems, laboratory automation, and 3D printing. The ability of DC motors to achieve accurate and repeatable movements makes them suitable for tasks that demand high levels of precision.

These are just a few examples of how DC motors are used in robotics. The flexibility, controllability, and compactness of DC motors make them a popular choice in a wide range of robotic applications, contributing to the advancement of automation, exploration, healthcare, and other industries.

editor by CX 2024-04-30

China Good quality AC220V/110V ± 10% Input, DC 24V Output Electric Gate Motor for Silding Door vacuum pump distributors

Product Description

Product Description

In order to make the installation and configuration easier, we have developed this intelligent 1 button learning sliding door control board. The control board adopts advanced microcomputer chip, digital control, more practical functions, higher safety performance, easier installation and configuration. Fully compatible with the smartphone app network (WiFi/3G/4G/5G) control and bluetooth control and many other features.

Features

1. Anti-rush design.

At the first operation after each power on, the motor runs in slow motion to the limit point throughout the process to avoid rushing out of the limit. When the door reaches the limit point, the motor can only be operated by pressing the button of the opposite direction to prevent the limit from being broken out. (Notice: It has the power off protection function when in place, and the motor only moves in the opposite direction when repowered).

2. Master-slave mode available.

Two motors with the same control board on each can work synchronously. In this mode, infrared, ground sense, automatic door close and other functions are synchronized. Attention: Infrared, ground sense must be connected to the master motor.

3. Motor runtime protection.

To prevent the motor from running during the travel failure, the control board will automatically learn the motor running time without manual setting, and 10s will be added automatically as the time margin.

4. Auto-close function.

Time can be set from 1s to 250s before the door closes automatically. The default value is 3s.

5. Soft start and slow stop.

There’re soft start and slow stop features available. The distance and speed of the slow stop feature can be adjusted.

6. Stop & rebound against resistance.

Switchable between stop against resistance and rebound against resistance for the closing travel. Stop against resistance for the opening travle.

7. Onboard socket for bluetooth module.

A socket is integrated onboard for the insertion of the standalone bluetooth module (module not included by default).

8. One button configuration for internet control.

Can be directly paired with the internet controllers through pressing 1 button onboard, no copy procedure is required.

Product Parameters

| Working voltage: | AC220V/110V ± 10% input, DC 24V output. |

| Maximum Output Current: | 10A |

| Fuse: | AC220V 20A. |

| Remote control distance: | Over 30 CHINAMFG in open area |

| Ambient temperature range: | -25°~+75°. |

| Relative humidity: | <60%, NO CONDENSATION. |

Diagram

Configuration IntroductionDip Switch1: Remote Control One-key and Four-key Modes Switch

OFF position

Remote control with 4 independent keys functioning as Open, Close, Stop, Lock.When in the non-passageway mode, after pressing the Lock key, the Stop key needs to be pressed in prior to being able to operate.

ON position

(1) A single key on the remote is the one-key control key (The specific key pressed while pairing).

(2) Each key on the remote is a one-key control key.

Function setting

Turn and only turn 1 and 6 to ON, press SET once with a buzzer is the single key one-key mode, press again with 4 buzzers is the 4 keys one-key mode. Turn 6 to OFF after setting.

Dip Switch 2: Passageway Mode OFF PositionDisable the passageway mode. ON PositionEnable the passageway mode (1 at OFF, 2 at ON).

When the gate is closed at the limit position, press the Lock key will make the motor run in the opening motion for 6s.

Dip Switch 3: Auto-close OFF PositionDisable the auto-close function.

ON Position

Enable the auto-close funciton. Only when the gate is opened at the limit position will the countdown starts, then the gate will automatically close to the limit position.

Auto-close timer setting

Turn and only turn 3 and 6 to ON, each press on the SET key is 1s, set it as long as you

wish up to 250s. After setting, turn 6 to OFF.

Dip Switch 4: Slow Stop OFF PositionDisable the slow stop function. ON PositionEnable the slow stop function (Effective only after travel distance learning).

The speed of Slow Stop can be adjusted with the MT adjustor, turn it clockwise to gain the speed, turn it anti-clockwise to reduce the speed.

The distance of Slow Stop can be adjusted with the TIME adjustor, turn it clockwise to gain the distance, turn it anti-clockwise to reduce the distance.

Travel Distance Learning

Turn and only turn 4 and 6 to ON, then hold down the ONE key until the gate starts running auomatically and release. It will close to the limit and open to the limit, and close to the limit again with the slow stop effect. After 2 beeps, the travel distance learning procedure is complete.

Dip Switch 5: Startup Strength

OFF Position

Enable the slow start function. The gate runs at a slower speed for the first 2s, to reduce the tremble of the gate.

ON PositionMax start speed. The gate runs at the maximum speed from the very beginning.Dip Switch 6: Setting Key OFF PositionMake the settings take effect.

ON Position

Enable the setting mode for the One-key function, Auto-close function and Slow Stopfunctions. When the settings are set, turn this key to OFF to take effect.

Dip Switch 7: Resistance Stop & Rebound OFF PositionThe gate stops when running to either open or close.

ON Position

The gate stops against resistance when running to open. When running to close, the gate stops against resistance for 1s and then rebound.

Optimized resistance rebound adjustment

Make sure the motor functions properly. Turn on dip switch 7, then while the motor is in the motion of closing, rotate the FORCE adjustor anticlockwise to allow the door stops and return automatically, this is the threshold of the resistance force, it’s suggested to rotate the adjustor clockwise a little bit to set it as the final resistance force.

Dip Switch 8: Motor Rotation Direction Swap Swap this switch to reverse the rotation direction of the gear.Blue Dip Switch 1: Normally Closed/Open OFF PositionSet the motor status to normally open. ON PositionSet the motor status to normally closed.Blue Dip Switch 2: Master-slave Mode OFF PostionSet the current motor as the master motor. ON PositionSet the current motor as the slave motor.

Master-slave mode means 2 motors with the same control board installed on each work synchronously when the master motor is being operated. Connect 2 motors through the 485A+Binterfaces on both motors in parallel to realize the master-slave mode.

Remote Control Paring And DeletionPairing

Hold down the STUDY button on the control board for about 1s until a buzz, then hold down any key of the remote control, release it against a buzz, and the pairing procedure is complete. Repeat this step to pair more remotes. Up to 120 remotes can be paired with a single board.

Deletion

Hold down the STUDY button on the control board for about 7s, release it against 3 continuous buzzesto delete all paired remotes.

P.S.: After entering the pairing state, if no effective RF signal is sensed, the board will exit the pairing state automatically with a buzz and the LED returning to always on.

Gatelink Roling Code Learning Method

▪ Remote Without Locked Type (Button No Function).

▪ Press and hold the “Learn/Delete” button on the GateLink receiving board for about 1 second,the indicator will turn off,can hear the buzzer give a “didi”sound,to remind the user release the button,and then enter into remote learning type, press and hold the remote transponder any button(open/close/stop),release it after heard the buzzer give”didi”sound again,learning finished.

Remote With Locked Type (Button With Function)

▪ Press and hold the “Learn/Delete” button on the GateLink receiving board for about 1 second,the indicator will turn off,can hear the buzzer give a “didi”sound,to remind the user release the button,and then enter into remote learning type,press and hold the “Lock” button, release it after heard the buzzer give”didi”sound again,learning finished;

▪ If choosed the wrong mode, you can re-learn again. Repeat this step to learn multiple remote transponder, and the regular version can store up to 64 GateLink ID; (256 Gatelink ID can be optional also).

UNDER-V Indicator

1. When the voltage of the battery is in between 19 ~ 20V, the UNDER-V indicator is always on.2. When the voltage of the battery is lower than 19V, the UNDER-V indicator flashes constantly, the board enters the under-voltage state and will not carry out the motions of neither opening nor closing.BLE Indicator

1. When the bluetooth module is not bound, the BLE indicator flashes once per second constantly.

2. After binding, the BLE indicator flashes once per second when linked with the mobile app, and goes off when the app is quit.3. After holding down the BLE key for 5s to reset the bluetooth feature, the BLE indicator will stay on.Charge Indicator

1. When charging, the red LED is always on.

2. The red LED goes off after full charged.

Photocell Indicator

When triggered, the corresponding red LED is on, otherwise it stays off.

Stop Indicator

When triggered, the corresponding red LED is on, otherwise it stays off.

Manual Button Indicator

When triggered, the corresponding red LED is on, otherwise it stays off.

Closing Indicator

When triggered, the corresponding yellow LED is on, otherwise it stays off.

Opening Indicator

When triggered, the corresponding green LED is on, otherwise it stays off.

Loop Indicator

When triggered, the corresponding red LED is on, otherwise it stays off.

Closed Limiter Indicator

When the gate is closed at the limit position, the corresponding LED stays on, otherwise it’s off.

Open Limiter Indicator

When the gate is open at the limit position, the corresponding LED stays on, otherwise it’s off.

Buzzer Introduction

1. A buzz occurs each time a dip switch is dipped.

2. When in the unlocked status under the Lock mode, a buzz occurs when the LOCK button on the remote is pressed indicating the remote is locked. When in the locked statuse, press the STOP button on the remote causes 2 buzzes, and the remote is unlocked.

3. When both limit swithes are triggered at the same time, the buzzer keeps buzzing and the motor cannot be operated by any button, in this case the height of the magnet should be adjusted.

4. When the gate is at the open/closed limit position, if the open/close button on the remote is pressed, 3 continuous buzzes occur and no reaction happens.

5. Stop against resistance when opening will cause 3 continuous buzzes, stop/rebound against resistance when closing will cause 5 continuous buzzes.

Magnetic Limit Switch Installation Xihu (West Lake) Dis.

Move the gate to the ideal closed position, fix the magnet on the gear rack at the spot where the limit switch box is located and make sure the magnet is facing to the box. Do the same with another magnet for the open position at the other end of the racks. Make sure the magnet on the left is higher and the 1 on the right is lower. When at a certain limit position, the corresponding LED indicator on the board will stays on. If the 2 indicators are on at the same time along with a constant buzz, the height of the magnet needs to be adjusted.

M-S Mode (Double Machines Synchronized) Setup Xihu (West Lake) Dis.Connection

1. Turn the Master/Slave dip switch to ON on the master motor. Leave the switch at OFF on the slave motor.

2. Connect the A+ B- interfaces on the master motor to the corresponding interfaces on the slave motor.

After connecting, if the RUN indicators on both master and slave motors flashes synchronouly once per second, it’s properly set. Otherwise, check the wire connection or the status of the dip switches.Functions1. When the M-S mode is successfully set, the remotes paired with the slave motor and the Manual button, Study/Delete button on the slave motor are all out of function as well as the Open, Stop, Close functions of any external control devices connected with the slave motor.2. When operating the remotes paired with the master motor, and the Manual button, Study/Delete button on the master motor as well as the Open, Stop, Close functions of any external control devicesconnected with the master motor, the slave motor will carry out the same operations.3. The resistance stop/rebound function, photocell function, loop function on both motors can be triggered from either motor and carry out the corresponding function on the other at the same time.4. The auto-close function of the slave motor is overwritten by the master motor, if this function is supposed to be used, turn the AUTO CLOSE dip switch to ON on the master motor.5. The low speed rate and resistance force can be set on each motor separately.6. The limit function on each motor works separately, it is to be set on either motor before linking.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Technical Training |

|---|---|

| Warranty: | 2 Years |

| Structure: | Wheeled |

| Samples: |

US$ 240/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the speed control of a DC motor work, and what methods are commonly employed?

The speed control of a DC (Direct Current) motor is essential for achieving precise control over its rotational speed. Various methods can be employed to regulate the speed of a DC motor, depending on the specific application requirements. Here’s a detailed explanation of how speed control of a DC motor works and the commonly employed methods:

1. Voltage Control:

One of the simplest methods to control the speed of a DC motor is by varying the applied voltage. By adjusting the voltage supplied to the motor, the electromotive force (EMF) induced in the armature windings can be controlled. According to the principle of electromagnetic induction, the speed of the motor is inversely proportional to the applied voltage. Therefore, reducing the voltage decreases the speed, while increasing the voltage increases the speed. This method is commonly used in applications where a simple and inexpensive speed control mechanism is required.

2. Armature Resistance Control:

Another method to control the speed of a DC motor is by varying the armature resistance. By inserting an external resistance in series with the armature windings, the total resistance in the circuit increases. This increase in resistance reduces the armature current, thereby reducing the motor’s speed. Conversely, reducing the resistance increases the armature current and the motor’s speed. However, this method results in significant power loss and reduced motor efficiency due to the dissipation of excess energy as heat in the external resistance.

3. Field Flux Control:

Speed control can also be achieved by controlling the magnetic field strength of the motor’s stator. By altering the field flux, the interaction between the armature current and the magnetic field changes, affecting the motor’s speed. This method can be accomplished by adjusting the field current through the field windings using a field rheostat or by employing a separate power supply for the field windings. By increasing or decreasing the field flux, the speed of the motor can be adjusted accordingly. This method offers good speed regulation and efficiency but requires additional control circuitry.

4. Pulse Width Modulation (PWM):

Pulse Width Modulation is a widely used technique for speed control in DC motors. It involves rapidly switching the applied voltage on and off at a high frequency. The duty cycle, which represents the percentage of time the voltage is on, is varied to control the effective voltage applied to the motor. By adjusting the duty cycle, the average voltage across the motor is modified, thereby controlling its speed. PWM provides precise speed control, high efficiency, and low power dissipation. It is commonly employed in applications such as robotics, industrial automation, and electric vehicles.

5. Closed-Loop Control:

In closed-loop control systems, feedback from the motor’s speed or other relevant parameters is used to regulate the speed. Sensors such as encoders or tachometers measure the motor’s actual speed, which is compared to the desired speed. The difference, known as the error signal, is fed into a control algorithm that adjusts the motor’s input voltage or other control parameters to minimize the error and maintain the desired speed. Closed-loop control provides excellent speed regulation and accuracy, making it suitable for applications that require precise speed control, such as robotics and CNC machines.

These methods of speed control provide flexibility and adaptability to various applications, allowing DC motors to be effectively utilized in a wide range of industries and systems.

What is the significance of back EMF (electromotive force) in DC motor performance?

The significance of back EMF (electromotive force) in DC motor performance is crucial to understanding the behavior and operation of DC motors. Back EMF is an inherent characteristic of DC motors and plays a pivotal role in their efficiency, speed regulation, and overall performance. Here’s a detailed explanation of the significance of back EMF in DC motor performance:

When a DC motor operates, it generates a voltage known as back EMF or counter electromotive force. This voltage opposes the applied voltage and is caused by the rotation of the motor’s armature within the magnetic field. The back EMF is directly proportional to the rotational speed of the motor.

The significance of back EMF can be understood through the following aspects:

1. Speed Regulation:

Back EMF is crucial for regulating the speed of a DC motor. As the motor rotates faster, the back EMF increases, which reduces the effective voltage across the motor’s armature. Consequently, the armature current decreases, limiting the motor’s speed. This self-regulating characteristic helps maintain a relatively constant speed under varying load conditions. It allows the motor to deliver the required torque while preventing excessive speed that can potentially damage the motor or the driven equipment.

2. Efficiency:

Back EMF plays a significant role in the efficiency of a DC motor. When the motor is loaded and drawing current, the power supplied to the motor is the product of the armature current and the applied voltage. However, the electrical power converted into mechanical power is reduced by the power consumed by the back EMF. The back EMF represents the energy returned to the power supply as the motor generates its own voltage. By reducing the effective voltage across the motor, it helps minimize power losses due to electrical resistance and improves the overall efficiency of the motor.

3. Motor Protection:

The presence of back EMF also provides a level of protection to the motor. When a DC motor is operating and the load on the motor suddenly decreases, such as when the driven equipment is disconnected, the motor’s speed can increase rapidly. This increase in speed leads to a higher back EMF, which reduces the armature current and prevents excessive current flow. By limiting the current, the back EMF helps protect the motor from overloading and potential damage.

4. Voltage Regulation:

Back EMF affects the voltage regulation in a DC motor. When the motor is operating, the back EMF opposes the applied voltage. As the motor load increases, the voltage drop across the armature resistance and other internal losses also increase. The back EMF helps compensate for these voltage drops, ensuring that the motor receives an adequate voltage to maintain its performance and torque output.

5. Control and Dynamic Response:

Back EMF provides valuable information for motor control and dynamic response. By measuring the back EMF voltage, the rotational speed of the motor can be estimated, allowing for precise speed control and feedback. This information is crucial for applications that require accurate speed regulation, such as robotics or industrial automation.

In summary, the significance of back EMF in DC motor performance cannot be overstated. It influences speed regulation, efficiency, motor protection, voltage regulation, and control capabilities. By understanding and utilizing the inherent characteristics of back EMF, engineers can design and optimize DC motor systems for various applications, ensuring reliable and efficient operation.

Can DC motors be used in robotics, and if so, what are some notable applications?

Yes, DC (Direct Current) motors can be used in robotics, and they are widely employed in various robotic applications. DC motors offer several advantages that make them suitable for robotic systems, including their controllability, compact size, and versatility. Here’s a detailed explanation of how DC motors are used in robotics and some notable applications:

DC Motors in Robotics:

DC motors are commonly used in robotics due to their ability to provide precise speed control and torque output. They can be easily controlled by adjusting the voltage applied to the motor, allowing for accurate and responsive motion control in robotic systems. Additionally, DC motors can be designed in compact sizes, making them suitable for applications with limited space and weight constraints.

There are two main types of DC motors used in robotics:

- DC Brushed Motors: These motors have a commutator and carbon brushes that provide the electrical connection to the rotating armature. They are relatively simple in design and cost-effective. However, they may require maintenance due to brush wear.

- DC Brushless Motors: These motors use electronic commutation instead of brushes, resulting in improved reliability and reduced maintenance requirements. They are often more efficient and offer higher power density compared to brushed motors.

Notable Applications of DC Motors in Robotics:

DC motors find applications in various robotic systems across different industries. Here are some notable examples:

1. Robotic Manipulators: DC motors are commonly used in robotic arms and manipulators to control the movement of joints and end-effectors. They provide precise control over position, speed, and torque, allowing robots to perform tasks such as pick-and-place operations, assembly, and material handling in industrial automation, manufacturing, and logistics.

2. Mobile Robots: DC motors are extensively utilized in mobile robots, including autonomous vehicles, drones, and rovers. They power the wheels or propellers, enabling the robot to navigate and move in different environments. DC motors with high torque output are particularly useful for off-road or rugged terrain applications.

3. Humanoid Robots: DC motors play a critical role in humanoid robots, which aim to replicate human-like movements and capabilities. They are employed in various joints, including those of the head, arms, legs, and hands, allowing humanoid robots to perform complex movements and tasks such as walking, grasping objects, and facial expressions.

4. Robotic Exoskeletons: DC motors are used in robotic exoskeletons, which are wearable devices designed to enhance human strength and mobility. They provide the necessary actuation and power for assisting or augmenting human movements, such as walking, lifting heavy objects, and rehabilitation purposes.

5. Educational Robotics: DC motors are popular in educational robotics platforms and kits, including those used in schools, universities, and hobbyist projects. They provide a cost-effective and accessible way for students and enthusiasts to learn about robotics, programming, and control systems.

6. Precision Robotics: DC motors with high-precision control are employed in applications that require precise positioning and motion control, such as robotic surgery systems, laboratory automation, and 3D printing. The ability of DC motors to achieve accurate and repeatable movements makes them suitable for tasks that demand high levels of precision.

These are just a few examples of how DC motors are used in robotics. The flexibility, controllability, and compactness of DC motors make them a popular choice in a wide range of robotic applications, contributing to the advancement of automation, exploration, healthcare, and other industries.

editor by CX 2024-04-22

China Standard Sectional Garage Door Opener, DC Motor manufacturer

Product Description

As a powerful sectional garage door opener, it is quiet and stable when operating. The powerAutomatic closure function, self-lock function and manual release in case of power failure making it easy for you to use.

Garage Door opener 1011.106DC

Features:

*Computerised precision travel limit, soft start and close.

*Digits screen makes the setting easier

*Automatical open softly, quiet and stable operation

*Automatical closure function setting available

*Automatically reverse safety system

*Force sensing systems constantly adapt to compensate for minor changes in door load from weather and door age

*One button remote control with step by step control mode

*Self-lock in closure position

*Manual release in case of power failure, all settings retained even after power loss

*Automatically rebound to open against obstruction in closing

*Automatically stop against obstruction in opening

*Alarm against illegal breaker

*Auto courtesy light, inner light illuminates for 3-4 minutes when the opener receive signal from remote control

*Available for connection to safety beam sensor, pushbutton switch, battery backup

*5 levels adjustable force

*Over load protection

Technical parameter:

| Specification | 1011.106A600 | 1011.106B800 | 1011.106C1000 | 1011.106D1200 |

| Input voltage(VAC, Hz) | 230V,50Hz | |||

| Rated power(W) | 110 | 150 | 198 | 220 |

| Drive force(N) | 600(1/3 HP) | 800 (1/2 HP) | 1000 (1+1/4 HP) | 1200 (1+3/4 HP) |

| Motor voltage(V) | 24V | |||

| Operation speed(cm/s) | 12 | |||

| Hold-open time(minutes) | 2.5 | |||

| Radio frequency(MHz) | 433.92 | |||

| Lifting height (m) | 2.4 | 2.7 | 3.0 | 3.4 |

| Door measurement (max)(m2) | 9 | 12 | 14 | 16 |

| Length of rail track(max)(m) | 3.0 | 3.3 | 3.6 | 4.0 |

| Ambient temperature(ºC) | -20~+60 | |||

| Revolution(rpm) | 50 | |||

| Water proof(IP) | 20 | |||

| Remote distance (max) m(ft) | 50(164) | |||

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 2 Years |

|---|---|

| Warranty: | 2 Years |

| Structure: | Wheeled |

| Driving Type: | Electromechanical |

| Electric Current Type: | DC |

| Brand: | Safedoor |

| Customization: |

Available

|

|

|---|

Can you explain the basic working principle behind a DC motor?

A DC (Direct Current) motor operates based on the fundamental principle of electromagnetic induction. It converts electrical energy into mechanical motion by utilizing the interaction between magnetic fields and current-carrying conductors. Here’s a detailed explanation of the basic working principle behind a DC motor:

1. Construction:

A DC motor consists of several key components:

- Stator: The stator is the stationary part of the motor and typically consists of permanent magnets or electromagnets that produce a fixed magnetic field.

- Rotor: The rotor is the moving part of the motor and is connected to the shaft. It contains coils or windings that carry the armature current.

- Armature: The armature is the core of the rotor that holds the armature windings. The windings are usually made of copper wire and are evenly spaced around the armature.

- Commutator: The commutator is a cylindrical ring attached to the rotor shaft. It consists of multiple segments, usually made of copper, that are insulated from each other.

- Brushes: The brushes are stationary contacts that make physical contact with the commutator segments. They are typically made of carbon or graphite and provide electrical connections to the armature windings.

2. Electromagnetic Induction:

When a current-carrying conductor is placed in a magnetic field, it experiences a force due to the interaction between the magnetic field and the current. This phenomenon is described by the right-hand rule, where the direction of the force is perpendicular to both the current direction and the magnetic field direction.

3. Motor Operation:

When a DC motor is powered, a DC voltage is applied to the armature windings through the brushes and commutator. The current flowing through the armature windings creates a magnetic field around the windings. This magnetic field interacts with the fixed magnetic field produced by the stator, resulting in a force that causes the rotor to rotate.

4. Commutation:

The commutation process is crucial for the continuous rotation of the rotor in a DC motor. As the rotor spins, the brushes make contact with different commutator segments, effectively reversing the direction of the current in the armature windings at the appropriate timing. This reversal of current flow ensures that the torque generated in the armature windings is always in the same direction, allowing for continuous rotation of the rotor.

5. Speed Control:

The speed of a DC motor can be controlled by varying the applied voltage. Reducing the voltage results in a decrease in the magnetic field strength, which in turn decreases the force acting on the armature windings. This reduction in force leads to a decrease in the motor’s speed. Conversely, increasing the voltage increases the speed of the motor. Precise speed control can be achieved by using electronic circuits to regulate the voltage supplied to the motor.

6. Advantages and Applications:

DC motors offer several advantages, including:

- High starting torque, making them suitable for applications requiring high initial force.

- Excellent speed control capabilities, allowing for precise and adjustable speed regulation.

- Relatively simple construction and ease of maintenance.

- Wide range of sizes and power ratings, making them adaptable to various applications.

DC motors find extensive use in numerous applications, such as robotics, industrial automation, electric vehicles, appliances, and more.

By understanding the basic working principle behind a DC motor, one can appreciate its functionality and explore its applications in different fields.

Can DC motors be used in renewable energy systems, such as wind turbines or solar tracking systems?

Yes, DC (Direct Current) motors can be effectively used in various renewable energy systems, including wind turbines and solar tracking systems. The unique characteristics and advantages of DC motors make them well-suited for these applications. Here’s a detailed explanation of how DC motors can be utilized in renewable energy systems:

1. Wind Turbines:

DC motors can be employed in wind turbines to convert the mechanical energy of the wind into electrical energy. There are two common configurations:

a. Direct Drive Wind Turbines:

In direct drive wind turbines, the rotor of the turbine is directly connected to a DC generator. The rotor’s rotational motion is transmitted directly to the generator, which produces DC electrical power. DC motors can be used as DC generators in this configuration. The advantage of using DC motors/generators is their simplicity, reliability, and ability to operate efficiently at variable speeds, which is beneficial in varying wind conditions.

b. Hybrid Wind Turbines:

Hybrid wind turbines combine both aerodynamic and electrical conversion systems. In this configuration, DC motors can be utilized for the pitch control mechanism and yaw control system. The pitch control mechanism adjusts the angle of the turbine blades to optimize performance, while the yaw control system enables the turbine to align itself with the wind direction. DC motors provide precise control and responsiveness required for these functions.

2. Solar Tracking Systems:

DC motors are commonly employed in solar tracking systems to maximize the efficiency of solar panels by optimizing their orientation towards the sun. There are two main types of solar tracking systems:

a. Single-Axis Solar Tracking Systems:

Single-axis solar tracking systems adjust the inclination of solar panels along a single axis (typically the east-west axis) to track the movement of the sun throughout the day. DC motors can be used to drive the rotation mechanism that adjusts the panel’s tilt angle. By continuously adjusting the panel’s position to face the sun directly, the solar energy harvested can be significantly increased, resulting in higher energy output compared to fixed solar panel installations.

b. Dual-Axis Solar Tracking Systems:

Dual-axis solar tracking systems adjust the inclination of solar panels along both the east-west and north-south axes to track the sun’s movement throughout the day and throughout the year. DC motors are utilized in the rotation mechanisms for both axes. This type of solar tracking system provides the highest possible energy yield by keeping the solar panels perpendicular to the sun’s rays at all times, maximizing the exposure to sunlight.

DC motors are preferred in renewable energy systems due to their advantages, including:

- Efficiency at Variable Speeds: DC motors can operate efficiently at varying speeds, making them suitable for applications with fluctuating wind speeds or changing solar angles.

- Control and Precision: DC motors offer precise control and responsiveness, allowing for accurate tracking and adjustment in wind turbines and solar tracking systems.

- Reliability: DC motors are known for their reliability, with fewer moving parts compared to other motor types, reducing the risk of failure in remote or harsh environments.

- Compatibility with Energy Storage Systems: DC motors can easily be integrated with energy storage systems, such as batteries or supercapacitors, to store excess electrical energy generated by wind turbines or solar panels.

In conclusion, DC motors can be effectively utilized in renewable energy systems such as wind turbines and solar tracking systems. Their efficiency, control capabilities, reliability, and compatibility with energy storage systems make them a suitable choice for these applications, contributing to the advancement of sustainable energy generation.

What are the environmental implications of using DC motors, particularly in green technologies?

DC (Direct Current) motors offer several environmental benefits when used in green technologies. Their characteristics and operational advantages contribute to reducing environmental impact compared to other motor types. Here’s a detailed explanation of the environmental implications of using DC motors, particularly in green technologies:

1. Energy Efficiency:

DC motors are known for their high energy efficiency. Compared to AC (Alternating Current) motors, DC motors generally have lower energy losses and can convert a larger proportion of electrical input power into mechanical output power. This increased efficiency results in reduced energy consumption, leading to lower greenhouse gas emissions and decreased reliance on fossil fuels for electricity generation.

2. Renewable Energy Integration:

DC motors are well-suited for integration with renewable energy sources. Many green technologies, such as solar photovoltaic systems and wind turbines, produce DC power. By utilizing DC motors directly in these systems, the need for power conversion from DC to AC can be minimized, reducing energy losses associated with conversion processes. This integration improves the overall system efficiency and contributes to a more sustainable energy infrastructure.

3. Battery-Powered Applications:

DC motors are commonly used in battery-powered applications, such as electric vehicles and portable devices. The efficiency of DC motors ensures optimal utilization of the limited energy stored in batteries, resulting in extended battery life and reduced energy waste. By utilizing DC motors in these applications, the environmental impact of fossil fuel consumption for transportation and energy storage is reduced.

4. Reduced Emissions:

DC motors, especially brushless DC motors, produce fewer emissions compared to internal combustion engines or motors that rely on fossil fuels. By using DC motors in green technologies, such as electric vehicles or electrically powered equipment, the emission of greenhouse gases and air pollutants associated with traditional combustion engines is significantly reduced. This contributes to improved air quality and a reduction in overall carbon footprint.

5. Noise Reduction:

DC motors generally operate with lower noise levels compared to some other motor types. The absence of brushes in brushless DC motors and the smoother operation of DC motor designs contribute to reduced noise emissions. This is particularly beneficial in green technologies like electric vehicles or renewable energy systems, where quieter operation enhances user comfort and minimizes noise pollution in residential or urban areas.

6. Recycling and End-of-Life Considerations:

DC motors, like many electrical devices, can be recycled at the end of their operational life. The materials used in DC motors, such as copper, aluminum, and various magnets, can be recovered and reused, reducing the demand for new raw materials and minimizing waste. Proper recycling and disposal practices ensure that the environmental impact of DC motors is further mitigated.

The use of DC motors in green technologies offers several environmental benefits, including increased energy efficiency, integration with renewable energy sources, reduced emissions, noise reduction, and the potential for recycling and end-of-life considerations. These characteristics make DC motors a favorable choice for sustainable and environmentally conscious applications, contributing to the transition to a greener and more sustainable future.

editor by CX 2024-04-22

China manufacturer CHINAMFG Slg51703 Automatic Sliding Door Motor AC DC for 800kg Sliding Gate vacuum pump for ac

Product Description

Product description

Installation drawing

Safety Instruction

Please ensure that the using power voltage matches with the supply voltage of gate opener (AC110V or AC220V); kids are forbidden to touch the control devices or the remote-control unit. The remote-control unit is controlled by a single button mode or 3 button mode (please refer to the instructions of the remote control in accordance with the actual gate opener type). The indicator light on the remote-control unit will flicker when the button on it is pressed. Main engine and gate can be unlocked by disengagement wrench and the gate can move with manual operation after disengagement. Please ensure that no 1 is around the main engine or gate when the switch is operated and it is usually demanded to examine the stability of installation. Please temporarily stop using if the main engine needs repairing or regulation.

Our Exhibition

Company profile

Certification

CE-SLG5280X-LVD

CE-SLG5280X-EMC

FAQ

1. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Transmitter,Tubular Motor Receiver,Sliding Gate Opener,Garage Door Opener,Photocell

3. Why should you buy from us not from other suppliers?

CHINAMFG is professional designer and qualified manufacturer of the automatic door control systems.We have 15 years experience We

have sliding/garage/swing/rolling shutter opener and control systems,transmitters,receivers,photocell,flash lamp,keypad etc.

Q4.How can i get a price of needed garage door opener?

A: Please give the exactly size and quantity of your required door. We can give you a detail quotation based on your requirements.

Q4.We want to be your agent of our area. How to apply for this?

A: Please send your ideal and your profile to any e-mails of us .Let’s talk more.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online |

|---|---|

| Warranty: | Online |

| Structure: | Wheeled |

| Samples: |

US$ 98/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the speed control of a DC motor work, and what methods are commonly employed?

The speed control of a DC (Direct Current) motor is essential for achieving precise control over its rotational speed. Various methods can be employed to regulate the speed of a DC motor, depending on the specific application requirements. Here’s a detailed explanation of how speed control of a DC motor works and the commonly employed methods:

1. Voltage Control:

One of the simplest methods to control the speed of a DC motor is by varying the applied voltage. By adjusting the voltage supplied to the motor, the electromotive force (EMF) induced in the armature windings can be controlled. According to the principle of electromagnetic induction, the speed of the motor is inversely proportional to the applied voltage. Therefore, reducing the voltage decreases the speed, while increasing the voltage increases the speed. This method is commonly used in applications where a simple and inexpensive speed control mechanism is required.

2. Armature Resistance Control:

Another method to control the speed of a DC motor is by varying the armature resistance. By inserting an external resistance in series with the armature windings, the total resistance in the circuit increases. This increase in resistance reduces the armature current, thereby reducing the motor’s speed. Conversely, reducing the resistance increases the armature current and the motor’s speed. However, this method results in significant power loss and reduced motor efficiency due to the dissipation of excess energy as heat in the external resistance.

3. Field Flux Control:

Speed control can also be achieved by controlling the magnetic field strength of the motor’s stator. By altering the field flux, the interaction between the armature current and the magnetic field changes, affecting the motor’s speed. This method can be accomplished by adjusting the field current through the field windings using a field rheostat or by employing a separate power supply for the field windings. By increasing or decreasing the field flux, the speed of the motor can be adjusted accordingly. This method offers good speed regulation and efficiency but requires additional control circuitry.

4. Pulse Width Modulation (PWM):

Pulse Width Modulation is a widely used technique for speed control in DC motors. It involves rapidly switching the applied voltage on and off at a high frequency. The duty cycle, which represents the percentage of time the voltage is on, is varied to control the effective voltage applied to the motor. By adjusting the duty cycle, the average voltage across the motor is modified, thereby controlling its speed. PWM provides precise speed control, high efficiency, and low power dissipation. It is commonly employed in applications such as robotics, industrial automation, and electric vehicles.

5. Closed-Loop Control:

In closed-loop control systems, feedback from the motor’s speed or other relevant parameters is used to regulate the speed. Sensors such as encoders or tachometers measure the motor’s actual speed, which is compared to the desired speed. The difference, known as the error signal, is fed into a control algorithm that adjusts the motor’s input voltage or other control parameters to minimize the error and maintain the desired speed. Closed-loop control provides excellent speed regulation and accuracy, making it suitable for applications that require precise speed control, such as robotics and CNC machines.

These methods of speed control provide flexibility and adaptability to various applications, allowing DC motors to be effectively utilized in a wide range of industries and systems.

Can you explain the concept of armature winding in a DC motor?

In a DC (Direct Current) motor, the armature winding is a crucial component that plays a significant role in the motor’s operation. It is responsible for producing the magnetic field that interacts with the stator’s magnetic field, resulting in the generation of torque and the rotation of the motor. Here’s a detailed explanation of the concept of armature winding in a DC motor:

The armature winding is a coil or set of coils made of insulated wire that is wound around the armature core, which is typically a laminated iron core. The armature winding is located on the rotor of the motor and is connected to the commutator. It carries the armature current, which is the current that flows through the winding to create the magnetic field. The armature winding is usually made of copper wire due to its excellent electrical conductivity.

When a current passes through the armature winding, it generates a magnetic field around the winding according to Ampere’s circuital law. The direction of the magnetic field is determined by the right-hand rule, where the thumb represents the direction of the current flow, and the curled fingers indicate the direction of the magnetic field.

The interaction between the magnetic field produced by the armature winding and the magnetic field produced by the stator’s permanent magnets or electromagnets creates a mechanical force, known as torque. This torque causes the rotor to rotate, converting electrical energy into mechanical motion.

The armature winding is designed in such a way that it produces a multipole magnetic field. The number of poles in the winding corresponds to the number of poles in the stator’s magnetic field. This ensures that the magnetic fields of the armature and stator are properly aligned for efficient torque generation.

The armature winding is connected to the commutator, which is a cylindrical ring with multiple segments that are insulated from each other. As the rotor spins, the brushes make physical contact with different segments of the commutator, effectively reversing the direction of the current in the armature winding. This reversal of current flow ensures that the torque generated in the armature winding is always in the same direction, enabling continuous rotation of the rotor.

The design and configuration of the armature winding, including the number of turns, wire gauge, and connection scheme, can influence the motor’s performance characteristics, such as torque, speed, and efficiency. Optimal winding design is crucial for achieving the desired motor performance in various applications.

In summary, the armature winding in a DC motor is responsible for producing the magnetic field that interacts with the stator’s magnetic field, resulting in the generation of torque and the rotation of the motor. It is a critical component that facilitates the conversion of electrical energy into mechanical motion.

What are the advantages and disadvantages of using DC motors in automotive applications?

DC (Direct Current) motors have been used in automotive applications for many years, although they have been largely replaced by other motor types such as AC (Alternating Current) motors and brushless DC motors in modern vehicles. However, there are still some advantages and disadvantages associated with using DC motors in automotive applications. Here’s a detailed explanation of the advantages and disadvantages:

Advantages of Using DC Motors in Automotive Applications:

1. Cost: DC motors tend to be less expensive compared to other motor types, such as AC motors or brushless DC motors. This cost advantage can make them an attractive option for certain automotive applications, especially in budget-conscious scenarios.

2. Simple Control: DC motors have a relatively simple control system. By adjusting the voltage applied to the motor, the speed and torque can be easily controlled. This simplicity of control can be advantageous in automotive applications where basic speed control is sufficient.

3. High Torque at Low Speeds: DC motors can provide high torque even at low speeds, making them suitable for applications that require high starting torque or precise low-speed control. This characteristic can be beneficial for automotive applications such as power windows, windshield wipers, or seat adjustments.

4. Compact Size: DC motors can be designed in compact sizes, making them suitable for automotive applications where space is limited. Their small form factor allows for easier integration into tight spaces within the vehicle.

Disadvantages of Using DC Motors in Automotive Applications:

1. Limited Efficiency: DC motors are typically less efficient compared to other motor types, such as AC motors or brushless DC motors. They can experience energy losses due to brush friction and electrical resistance, resulting in lower overall efficiency. Lower efficiency can lead to increased power consumption and reduced fuel economy in automotive applications.

2. Maintenance Requirements: DC motors that utilize brushes for commutation require regular maintenance. The brushes can wear out over time and may need to be replaced periodically, adding to the maintenance and operating costs. In contrast, brushless DC motors or AC motors do not have this maintenance requirement.

3. Limited Speed Range: DC motors have a limited speed range compared to other motor types. They may not be suitable for applications that require high-speed operation or a broad range of speed control. In automotive applications where high-speed performance is crucial, other motor types may be preferred.

4. Electromagnetic Interference (EMI): DC motors can generate electromagnetic interference, which can interfere with the operation of other electronic components in the vehicle. This interference may require additional measures, such as shielding or filtering, to mitigate its effects and ensure proper functioning of other vehicle systems.

5. Brush Wear and Noise: DC motors that use brushes can produce noise during operation, and the brushes themselves can wear out over time. This brush wear can result in increased noise levels and potentially impact the overall lifespan and performance of the motor.

While DC motors offer certain advantages in terms of cost, simplicity of control, and high torque at low speeds, they also come with disadvantages such as limited efficiency, maintenance requirements, and electromagnetic interference. These factors have led to the adoption of other motor types, such as brushless DC motors and AC motors, in many modern automotive applications. However, DC motors may still find use in specific automotive systems where their characteristics align with the requirements of the application.

editor by CX 2024-04-17

China Custom High Torque 12V 24V Micro DC Wiper Worm Gear Motor 12 24 Volt Automatic Electric Garage Sliding Gate Door Opener Brush DC Motor vacuum pump distributors

Product Description

High Torque 12V 24V Micro Dc Wiper Worm Gear Motor 12 24 Volt Automatic Electric Garage Sliding Gate Door Opener Brush Dc Motor

1)Product Description:

1°size:Diameter 59mm

2°lifespan:5000 hours

3°gear material: plastic or brass

4°IP rate:IP54

2)Complete Specification:

3)Motor Drawing:

Shaft drawing:

4)Application:

welding machine, electrical household, CHINAMFG machinery, office intelligent equipment, hotel leisure, antomated machine and so on.

Motor Voltage: DC12V, 24V,42V,48V,90V,110V ,300V

Motor Rated Power:15W, 25W,30W,45W,65W, 95W,120W,150W,180W

Motor no-load Speed:15RPM, 30RPM,60RPM,80RM,120RPM,150RPM,180RPM,200RPM,220RPM.

5)Factory show:

Transfer way:

7)RFQ:

Q: Are you trading company or manufacturer ?

A: We are Integration of industry and trade, with over 20 years experience in DC worm gear motor. Our company have accumulated skilled production line, complete management and powerful research support, which could match all of the customers’ requirements and make them satisfaction.

Q: What is your main product?

– DC Motor: Gear motor, Square motor, Stepped motor, and Micro motor

-Welding equipment: Wire feeder, Welding rod, Welding Torch, Earth clamp, Electrode holder, and Rectifier

Q: What if I don’t know which DC motor I need?

A: Don’t worry, Send as much information as you can, our team will help you find the right 1 you are looking for.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Q: How to delivery:

A: By sea – Buyer appoint forwarder, or our sales team find suitable forwarder for buyers.

By air – Buyer offer collect express account, or our sales team find suitable express for buyers. (Mostly for sample)

Others – Actually,samples send by DHL,UPS, TNT and Fedex etc. We arrange to delivery goods to some place from China appointed by buyers.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial, Household Appliances, Car, Power Tools |

|---|---|

| Operating Speed: | Constant Speed |

| Excitation Mode: | Excited |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How is the efficiency of a gear motor measured, and what factors can affect it?

The efficiency of a gear motor is a measure of how effectively it converts electrical input power into mechanical output power. It indicates the motor’s ability to minimize losses and maximize its energy conversion efficiency. The efficiency of a gear motor is typically measured using specific methods, and several factors can influence it. Here’s a detailed explanation:

Measuring Efficiency:

The efficiency of a gear motor is commonly measured by comparing the mechanical output power (Pout) to the electrical input power (Pin). The formula to calculate efficiency is:

Efficiency = (Pout / Pin) * 100%

The mechanical output power can be determined by measuring the torque (T) produced by the motor and the rotational speed (ω) at which it operates. The formula for mechanical power is:

Pout = T * ω

The electrical input power can be measured by monitoring the current (I) and voltage (V) supplied to the motor. The formula for electrical power is:

Pin = V * I

By substituting these values into the efficiency formula, the efficiency of the gear motor can be calculated as a percentage.

Factors Affecting Efficiency:

Several factors can influence the efficiency of a gear motor. Here are some notable factors:

- Friction and Mechanical Losses: Friction between moving parts, such as gears and bearings, can result in mechanical losses and reduce the overall efficiency of the gear motor. Minimizing friction through proper lubrication, high-quality components, and efficient design can help improve efficiency.

- Gearing Efficiency: The design and quality of the gears used in the gear motor can impact its efficiency. Gear trains can introduce mechanical losses due to gear meshing, misalignment, or backlash. Using well-designed gears with proper tooth profiles and minimizing gear train losses can improve efficiency.

- Motor Type and Construction: Different types of motors (e.g., brushed DC, brushless DC, AC induction) have varying efficiency characteristics. Motor construction, such as the quality of magnetic materials, winding resistance, and rotor design, can also affect efficiency. Choosing motors with higher efficiency ratings can improve overall gear motor efficiency.

- Electrical Losses: Electrical losses, such as resistive losses in motor windings or in the motor drive circuitry, can reduce efficiency. Minimizing resistance, optimizing motor drive electronics, and using efficient control algorithms can help mitigate electrical losses.

- Load Conditions: The operating conditions and load characteristics placed on the gear motor can impact its efficiency. Heavy loads, high speeds, or frequent acceleration and deceleration can increase losses and reduce efficiency. Matching the gear motor’s specifications to the application requirements and optimizing load conditions can improve efficiency.

- Temperature: Elevated temperatures can significantly affect the efficiency of a gear motor. Excessive heat can increase resistive losses, reduce lubrication effectiveness, and affect the magnetic properties of motor components. Proper cooling and thermal management techniques are essential to maintain optimal efficiency.

By considering these factors and implementing measures to minimize losses and optimize performance, the efficiency of a gear motor can be enhanced. Manufacturers often provide efficiency specifications for gear motors, allowing users to select motors that best meet their efficiency requirements for specific applications.

What is the significance of gear reduction in gear motors, and how does it affect efficiency?

Gear reduction plays a significant role in gear motors as it enables the motor to deliver higher torque while reducing the output speed. This feature has several important implications for gear motors, including enhanced power transmission, improved control, and potential trade-offs in terms of efficiency. Here’s a detailed explanation of the significance of gear reduction in gear motors and its effect on efficiency:

Significance of Gear Reduction:

1. Increased Torque: Gear reduction allows gear motors to generate higher torque output compared to a motor without gears. By reducing the rotational speed at the output shaft, gear reduction increases the mechanical advantage of the system. This increased torque is beneficial in applications that require high torque to overcome resistance, such as lifting heavy loads or driving machinery with high inertia.

2. Improved Control: Gear reduction enhances the control and precision of gear motors. By reducing the speed, gear reduction allows for finer control over the motor’s rotational movement. This is particularly important in applications that require precise positioning or accurate speed control. The gear reduction mechanism enables gear motors to achieve smoother and more controlled movements, reducing the risk of overshooting or undershooting the desired position.

3. Load Matching: Gear reduction helps match the motor’s power characteristics to the load requirements. Different applications have varying torque and speed requirements. Gear reduction allows the gear motor to achieve a better match between the motor’s power output and the specific requirements of the load. It enables the motor to operate closer to its peak efficiency by optimizing the torque-speed trade-off.

Effect on Efficiency:

While gear reduction offers several advantages, it can also affect the efficiency of gear motors. Here’s how gear reduction impacts efficiency:

1. Mechanical Efficiency: The gear reduction process introduces mechanical components such as gears, bearings, and lubrication systems. These components introduce additional friction and mechanical losses into the system. As a result, some energy is lost in the form of heat during the gear reduction process. The efficiency of the gear motor is influenced by the quality of the gears, the lubrication used, and the overall design of the gear system. Well-designed and properly maintained gear systems can minimize these losses and optimize mechanical efficiency.

2. System Efficiency: Gear reduction affects the overall system efficiency by impacting the motor’s electrical efficiency. In gear motors, the motor typically operates at higher speeds and lower torques compared to a direct-drive motor. The overall system efficiency takes into account both the electrical efficiency of the motor and the mechanical efficiency of the gear system. While gear reduction can increase the torque output, it also introduces additional losses due to increased mechanical complexity. Therefore, the overall system efficiency may be lower compared to a direct-drive motor for certain applications.

It’s important to note that the efficiency of gear motors is influenced by various factors beyond gear reduction, such as motor design, control systems, and operating conditions. The selection of high-quality gears, proper lubrication, and regular maintenance can help minimize losses and improve efficiency. Additionally, advancements in gear technology, such as the use of precision gears and improved lubricants, can contribute to higher overall efficiency in gear motors.

In summary, gear reduction is significant in gear motors as it provides increased torque, improved control, and better load matching. However, gear reduction can introduce mechanical losses and affect the overall efficiency of the system. Proper design, maintenance, and consideration of application requirements are essential to optimize the balance between torque, speed, and efficiency in gear motors.

What is a gear motor, and how does it combine the functions of gears and a motor?

A gear motor is a type of motor that incorporates gears into its design to combine the functions of gears and a motor. It consists of a motor, which provides the mechanical power, and a set of gears, which transmit and modify this power to achieve specific output characteristics. Here’s a detailed explanation of what a gear motor is and how it combines the functions of gears and a motor: