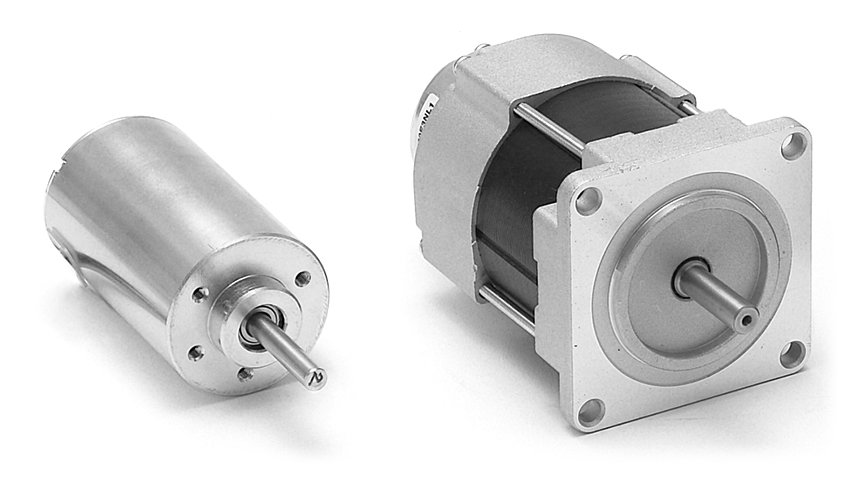

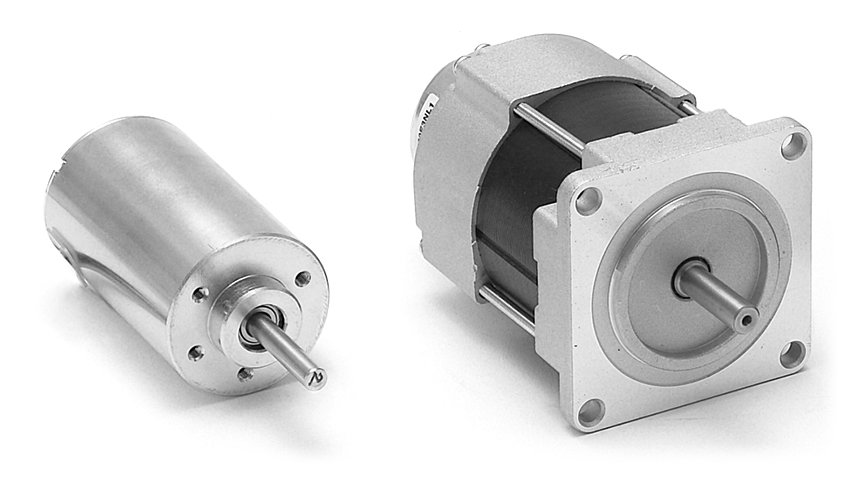

Product Description

Product Description

Product Parameters

| Model | Units | 110BSA125I030X-01 | 110BSA155I030X-01 | 110BSA185I030X-01 | 110BSA210I030X-01 |

| Number of poles | 8 | ||||

| Number of phase | 3 | ||||

| Rated voltage | VDC | 310 | 310 | 310 | 310 |

| Rated speed | RPM | 3000 | 3000 | 3000 | 3000 |

| Continuous stall torque | N.m | 2.2 | 4.8 | 7.164 | 8.592 |

| Rated torque | N.m | 2 | 4 | 6 | 7.16 |

| Rated power | W | 625 | 1250 | 1885 | 2249 |

| Peak torque | N.m | 6 | 12 | 17.91 | 21.48 |

| Peak current | A | 8 | 14.7 | 26 | 31 |

| Torque constant | Nm/A | 0.77 | 0.77 | 0.689 | 0.689 |

| Back E.M.F | V/KRPM | 54.8 | 54.8 | 54.8 | 54.8 |

| Rotor Inertia | g·cm² | 1.9 | 3.3 | 5 | 5.9 |

| Body length | mm | 125 | 155 | 185 | 210 |

| Voltage range | VDC | 48-310 | |||

| Speed range | RPM | 1000-3000 | |||

| Weight | Kg | 4.8 | 5.2 | 5.5 | 6 |

Application Area

Our Advantages

01 Quality Advantage 02 Cost Advantage 03 Delivery Advantage

The company introduced IATF16949 quality Application of SAP management system, Stepper motor 1 million pcs/month.

system to standardize the design and from raw materials to production process Brushless motor 80,000 pcs/ month.

manufacturing process, so that each link is strict control. Promote production automation, Servo motor 30,000 pcs/ month.

effectively controlled. improve process efficiency and reduce losses.

04 Technological Advantage 05 Service Advantage

Have the ability to accurately analyze and calculate the magnetic To provide customers with complete product solutions.

circuit and structure of the motor, so as to meet the design Active service, quick response.

requirements required by the product. Have a full set of product

testing and testing equipment. Implement project management and

product research.

Certifications

Company Profile

HangZhou 3X Motion Technologies Co., Ltd. was founded in 2002, specializing in the design and manufacture of various types of control motors, including: hybrid stepper motor, brush DC motor, brushless DC motor, AC servo motor, gearbox motor, driver, controller and other high-quality products. The products are suitable for robots, packing machinery, textile machinery, automatic doors, wheelchairs, medical instruments, printing machinery, intelligent logistics equipment, and other electromechanical integrated motion control products.

All products can be provided to the USA, Europe, Southeast Asia, and all over the world. The factory is located in HangZhou city, ZheJiang province, China. With a total of 300 employees and a plant area of 15,000 square meters, the company has an annual output of 10 million units of various types of motors and a sales volume of 320 million CNY.

Exhibition Information

FAQ

Q: What kind of motors can you provide?

A: At present, we mainly produce brushless DC motors, Servo motors, Hybrid stepping motors, and brushless conveyor roller etc.

Q: Can l get some samples?

A: It depends. If only a few samples for personal use or replacement, I am afraid it’ll be difficult for us to provide because all of our motors are custom made and no stock available if there are no further needs. If just sample testing before the official order and our MOQ, price and other terms are acceptable,we’d love to provide samples.

Q: Can you send me a price list?

A: For all of our motors, they are customized based on different requirements like lifetime, noise, voltage, and shaft etc. The price also varies according to annual quantity. So it’s really difficult for us to provide a price list. If you can share your detailed requirements and annual quantity, we’ll see what offer we can provide.

Q. What about wait times?

A: Samples take 7-10 days.

Q: How do you ship the goods? How long will it take to get there?

A: We usually ship by air. It usually takes 7-15 days to arrive. Please contact us if you need another mode of transportation before shipping.

Q: Can you provide OEM or ODM service?

A: Yes,OEM and ODM are both available, we have the professional R&D dept which can provide professional solutions for you.

Q: What’s the lead time for a regular order?

A: For orders, the standard lead time is 15-20 days and this time can be shorter or longer based on the different model, period and quantity.

Q: What are your payment terms?

A: T/T and other payment methods are available. Please contact us with the payment method you require before ordering. Payment terms: 30%-50% deposit, balance paid before delivery.

Q: Can my logo be printed on the product?

A. Yes. Please inform and authorize us officially before we produce, and confirm the design according to the sample.

Q: Can l visit your factory before we place an order?

A: Welcome to visit our factory, we are very pleased if we have the chance to know each other more.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial, Household Appliances, Car, Power Tools |

|---|---|

| Operating Speed: | Adjust Speed |

| Excitation Mode: | Excited |

| Function: | Control, Driving |

| Casing Protection: | Open Type |

| Number of Poles: | 8 |

| Samples: |

US$ 144/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does the speed control of a DC motor work, and what methods are commonly employed?

The speed control of a DC (Direct Current) motor is essential for achieving precise control over its rotational speed. Various methods can be employed to regulate the speed of a DC motor, depending on the specific application requirements. Here’s a detailed explanation of how speed control of a DC motor works and the commonly employed methods:

1. Voltage Control:

One of the simplest methods to control the speed of a DC motor is by varying the applied voltage. By adjusting the voltage supplied to the motor, the electromotive force (EMF) induced in the armature windings can be controlled. According to the principle of electromagnetic induction, the speed of the motor is inversely proportional to the applied voltage. Therefore, reducing the voltage decreases the speed, while increasing the voltage increases the speed. This method is commonly used in applications where a simple and inexpensive speed control mechanism is required.

2. Armature Resistance Control:

Another method to control the speed of a DC motor is by varying the armature resistance. By inserting an external resistance in series with the armature windings, the total resistance in the circuit increases. This increase in resistance reduces the armature current, thereby reducing the motor’s speed. Conversely, reducing the resistance increases the armature current and the motor’s speed. However, this method results in significant power loss and reduced motor efficiency due to the dissipation of excess energy as heat in the external resistance.

3. Field Flux Control:

Speed control can also be achieved by controlling the magnetic field strength of the motor’s stator. By altering the field flux, the interaction between the armature current and the magnetic field changes, affecting the motor’s speed. This method can be accomplished by adjusting the field current through the field windings using a field rheostat or by employing a separate power supply for the field windings. By increasing or decreasing the field flux, the speed of the motor can be adjusted accordingly. This method offers good speed regulation and efficiency but requires additional control circuitry.

4. Pulse Width Modulation (PWM):

Pulse Width Modulation is a widely used technique for speed control in DC motors. It involves rapidly switching the applied voltage on and off at a high frequency. The duty cycle, which represents the percentage of time the voltage is on, is varied to control the effective voltage applied to the motor. By adjusting the duty cycle, the average voltage across the motor is modified, thereby controlling its speed. PWM provides precise speed control, high efficiency, and low power dissipation. It is commonly employed in applications such as robotics, industrial automation, and electric vehicles.

5. Closed-Loop Control:

In closed-loop control systems, feedback from the motor’s speed or other relevant parameters is used to regulate the speed. Sensors such as encoders or tachometers measure the motor’s actual speed, which is compared to the desired speed. The difference, known as the error signal, is fed into a control algorithm that adjusts the motor’s input voltage or other control parameters to minimize the error and maintain the desired speed. Closed-loop control provides excellent speed regulation and accuracy, making it suitable for applications that require precise speed control, such as robotics and CNC machines.

These methods of speed control provide flexibility and adaptability to various applications, allowing DC motors to be effectively utilized in a wide range of industries and systems.

How is the efficiency of a DC motor determined, and what factors can affect it?

In a DC (Direct Current) motor, efficiency refers to the ratio of the motor’s output power (mechanical power) to its input power (electrical power). It is a measure of how effectively the motor converts electrical energy into mechanical work. The efficiency of a DC motor can be determined by considering several factors that affect its performance. Here’s a detailed explanation of how the efficiency of a DC motor is determined and the factors that can influence it:

The efficiency of a DC motor is calculated using the following formula:

Efficiency = (Output Power / Input Power) × 100%

1. Output Power: The output power of a DC motor is the mechanical power produced at the motor’s shaft. It can be calculated using the formula:

Output Power = Torque × Angular Speed

The torque is the rotational force exerted by the motor, and the angular speed is the rate at which the motor rotates. The output power represents the useful work or mechanical energy delivered by the motor.

2. Input Power: The input power of a DC motor is the electrical power supplied to the motor. It can be calculated using the formula:

Input Power = Voltage × Current

The voltage is the electrical potential difference applied to the motor, and the current is the amount of electrical current flowing through the motor. The input power represents the electrical energy consumed by the motor.

Once the output power and input power are determined, the efficiency can be calculated using the formula mentioned earlier.

Several factors can influence the efficiency of a DC motor:

1. Copper Losses:

Copper losses occur due to the resistance of the copper windings in the motor. These losses result in the conversion of electrical energy into heat. Higher resistance or increased current flow leads to greater copper losses and reduces the efficiency of the motor. Using thicker wire for the windings and minimizing resistance can help reduce copper losses.

2. Iron Losses:

Iron losses occur due to magnetic hysteresis and eddy currents in the motor’s iron core. These losses result in the conversion of electrical energy into heat. Using high-quality laminated iron cores and minimizing magnetic flux variations can help reduce iron losses and improve efficiency.

3. Friction and Windage Losses:

Friction and windage losses occur due to mechanical friction between moving parts and air resistance. These losses result in the conversion of mechanical energy into heat. Proper lubrication, efficient bearing systems, and aerodynamically optimized designs can help minimize friction and windage losses.

4. Brush and Commutator Losses:

In brushed DC motors, brush and commutator losses occur due to the friction and electrical resistance at the brush-commutator interface. These losses result in the conversion of electrical energy into heat. Using high-quality brushes and commutators, reducing brush voltage drop, and minimizing the number of commutator segments can help reduce these losses.

5. Magnetic Field Design:

The design of the magnetic field in the motor significantly affects its efficiency. Optimizing the magnetic field for the specific application, such as selecting appropriate magnet materials or designing efficient electromagnets, can improve the motor’s efficiency.

6. Motor Load:

The load on the motor, including the torque and speed requirements, can impact its efficiency. Operating the motor close to its optimal load conditions or utilizing speed control techniques, such as pulse width modulation (PWM), can help improve efficiency by reducing unnecessary power consumption.

7. Motor Size and Construction:

The size and construction of the motor can influence its efficiency. Properly sizing the motor for the intended application and optimizing the design for reduced losses, improved cooling, and efficient heat dissipation can enhance overall efficiency.

It’s important to note that the efficiency of a DC motor is typically highest at or near its rated load conditions. Deviating significantly from the rated load can result in reduced efficiency.

In summary, the efficiency of a DC motor is determined by comparing the output power to the input power. Factors such as copper losses, iron losses, friction and windage losses, brush and commutator losses, magnetic field design, motor load, and motor size and construction can all influence the efficiency of a DC motor. By considering and optimizing these factors, the overall efficiency of the motor can be improved.

What are the environmental implications of using DC motors, particularly in green technologies?

DC (Direct Current) motors offer several environmental benefits when used in green technologies. Their characteristics and operational advantages contribute to reducing environmental impact compared to other motor types. Here’s a detailed explanation of the environmental implications of using DC motors, particularly in green technologies:

1. Energy Efficiency:

DC motors are known for their high energy efficiency. Compared to AC (Alternating Current) motors, DC motors generally have lower energy losses and can convert a larger proportion of electrical input power into mechanical output power. This increased efficiency results in reduced energy consumption, leading to lower greenhouse gas emissions and decreased reliance on fossil fuels for electricity generation.

2. Renewable Energy Integration:

DC motors are well-suited for integration with renewable energy sources. Many green technologies, such as solar photovoltaic systems and wind turbines, produce DC power. By utilizing DC motors directly in these systems, the need for power conversion from DC to AC can be minimized, reducing energy losses associated with conversion processes. This integration improves the overall system efficiency and contributes to a more sustainable energy infrastructure.

3. Battery-Powered Applications:

DC motors are commonly used in battery-powered applications, such as electric vehicles and portable devices. The efficiency of DC motors ensures optimal utilization of the limited energy stored in batteries, resulting in extended battery life and reduced energy waste. By utilizing DC motors in these applications, the environmental impact of fossil fuel consumption for transportation and energy storage is reduced.

4. Reduced Emissions:

DC motors, especially brushless DC motors, produce fewer emissions compared to internal combustion engines or motors that rely on fossil fuels. By using DC motors in green technologies, such as electric vehicles or electrically powered equipment, the emission of greenhouse gases and air pollutants associated with traditional combustion engines is significantly reduced. This contributes to improved air quality and a reduction in overall carbon footprint.

5. Noise Reduction:

DC motors generally operate with lower noise levels compared to some other motor types. The absence of brushes in brushless DC motors and the smoother operation of DC motor designs contribute to reduced noise emissions. This is particularly beneficial in green technologies like electric vehicles or renewable energy systems, where quieter operation enhances user comfort and minimizes noise pollution in residential or urban areas.

6. Recycling and End-of-Life Considerations:

DC motors, like many electrical devices, can be recycled at the end of their operational life. The materials used in DC motors, such as copper, aluminum, and various magnets, can be recovered and reused, reducing the demand for new raw materials and minimizing waste. Proper recycling and disposal practices ensure that the environmental impact of DC motors is further mitigated.

The use of DC motors in green technologies offers several environmental benefits, including increased energy efficiency, integration with renewable energy sources, reduced emissions, noise reduction, and the potential for recycling and end-of-life considerations. These characteristics make DC motors a favorable choice for sustainable and environmentally conscious applications, contributing to the transition to a greener and more sustainable future.

editor by CX 2024-04-24

China supplier 6mm Low Rpm 3V DC Micro Gear Stepper Motor with Small Gearbox vacuum pump belt

Product Description

Product Description

Model: ZWBMD006006-711

Rated Voltage: 3V

No Load Speed: 26rpm

No load current: 40mA

Rated Speed: 22rpm

Rated Current: 100mA

Rated Torque: 296.9g.cm

Overall Length : 30.9mm

Rated Torque of Gear Box: 330g.cm

Instant Torque of Gear Box: 800g.cm

Gear Ratio: 711:1

Gear Box Length: 16.9mm

Specifications:

| Model | Application Parameters | Rated Torque of Gear Box | Instant Torque of Gear Box | Gear Ratio | Gear Box Length L1 |

|||||||

| Rated | At No Load | At Rated Load | Overall Length L |

|||||||||

| Voltage | Speed | Current | Speed | Current | Torque | |||||||

| VDC | rpm | mA | rpm | mA | gf.cm | mN.m | mm | gf.cm | gf.cm | mm | ||

| ZWBMD006006-110 | 3.0 | 166 | 37 | 140 | 100 | 54.3 | 5.33 | 28.5 | 330 | 800 | 110.6 | 14.5 |

| ZWBMD006006-148 | 3.0 | 124 | 37 | 105 | 100 | 72.8 | 7.14 | 28.5 | 330 | 800 | 148.1 | 14.5 |

| ZWBMD006006-198 | 3.0 | 93 | 37 | 78 | 100 | 97.5 | 9.56 | 28.5 | 330 | 800 | 198.4 | 14.5 |

| ZWBMD006006-266 | 3.0 | 69 | 37 | 58 | 100 | 130.5 | 12.80 | 28.5 | 330 | 800 | 265.7 | 14.5 |

| ZWBMD006006-531 | 3.0 | 35 | 40 | 29 | 100 | 221.7 | 21.74 | 30.9 | 330 | 800 | 530.8 | 16.9 |

| ZWBMD006006-711 | 3.0 | 26 | 40 | 21 | 100 | 296.9 | 29.12 | 30.9 | 330 | 800 | 711.0 | 16.9 |

| ZWBMD006006-952 | 3.0 | 19 | 40 | 16 | 95 | 330 | 32.36 | 30.9 | 330 | 800 | 952.2 | 16.9 |

| ZWBMD006006-1275 | 3.0 | 14 | 40 | 12 | 85 | 330 | 32.36 | 30.9 | 330 | 800 | 1275.2 | 16.9 |

| ZWBMD006006-1708 | 3.0 | 11 | 40 | 10 | 75 | 330 | 32.36 | 30.9 | 330 | 800 | 1707.9 | 16.9 |

above specifications just for reference and customizable according to requirements.

Please let us know your requirements and we will provide you with micro transmission solutions.

2D Drawing

Detailed Photos

Application

| Smart wearable devices | watch,VR,AR,XR and etc. |

| Household application | kitchen appliances, sewing machines, corn popper, vacuum cleaner, garden tool, sanitary ware, window curtain, intelligent closestool, sweeping robot, power seat, standing desk, electric sofa, TV, computer, treadmill, spyhole, cooker hood, electric drawer, electric mosquito net, intelligent cupboard, intelligent wardrobe, automatic soap dispenser, UV baby bottle sterilizer, lifting hot pot cookware, dishwasher, washing machine, food breaking machine, dryer, air conditioning, dustbin, coffee machine, whisk,smart lock,bread maker,Window cleaning robot and etc. |

| communication equipment | 5G base station,video conference,mobile phone and etc. |

| Office automation equipments | scanners, printers, multifunction machines copy machines, fax (FAX paper cutter), computer peripheral, bank machine, screen, lifting socket, display,notebook PC and etc. |

| Automotive products | conditioning damper actuator, car DVD,door lock actuator, retractable rearview mirror, meters, optic axis control device, head light beam level adjuster, car water pump, car antenna, lumbar support, EPB, car tail gate electric putter, HUD, head-up display, vehicle sunroof, EPS, AGS, car window, head restraint, E-booster, car seat, vehicle charging station and etc. |

| Toys and models | radio control model, automatic cruise control, ride-on toy, educational robot, programming robot, medical robot, automatic feeder, intelligent building blocks, escort robot and etc. |

| Medical equipments | blood pressure meter, breath machine, medical cleaning pump, medical bed, blood pressure monitors, medical ventilator, surgical staplers, infusion pump, dental instrument, self-clotting cutter, wound cleaning pump for orthopedic surgery,electronic cigarette, eyebrow pencil,fascia gun, , surgical robot,laboratory automation and etc. |

| Industrials | flow control valves, seismic testing,automatic reclosing,Agricultural unmanned aerial vehicle,automatic feeder ,intelligent express cabinet and etc. |

| Electric power tools | electric drill, screwdriver,garden tool and etc. |

| Precision instruments | optics instruments,automatic vending machine, wire-stripping machine and etc. |

| Personal care | tooth brush, hair clipper, electric shaver, massager, vibrator, hair dryer, rubdown machine, scissor hair machine, foot grinder,anti-myopia pen, facial beauty equipment, hair curler,Electric threading knife,POWER PERFECT PORE, Puff machine,eyebrow tweezers and etc. |

| Consumer electronics | camera, mobile phone,digital camera, automatic retracting device,camcorder, kinescope DVD,headphone stereo, cassette tape recorder, bluetooth earbud charging case, turntable, tablet,UAV(unmanned aerial vehicle),surveillance camera,PTZ camera, rotating smart speaker and etc. |

| robots | educational robot, programming robot, medical robot, escort robot and etc. |

Company Profile

HangZhou CHINAMFG Machinery & Electronics Co., Ltd was established in 2001,We provide the total drive solution for customers from design, tooling fabrication, components manufacturing and assembly.

Workshop

Testing Equipment

1) Competitive Advantages

- 1) Competitive Advantages

19+year experience in manufacturing motor gearbox

We provide technical support from r&d, prototype, testing, assembly and serial production , ODM &OEM

Competitive Price

Product Performance: Low noise, High efficiency, Long lifespan

Prompt Delivery: 15 working days after payment

Small Orders Accepted

2) Main Products

-

Precision reduction gearbox and its diameter:3.4mm-38mm,voltage:1.5-24V,power: 0.01-40W,output speed:5-2000rpm and output torque:1.0 gf.cm -50kgf.cm,

- Customized worm and gear transmission machinery;

- Precise electromechanical motion module;

- Precise component and assembly of plastic and metal powder injection.

Our Services

- ODM & OEM

- Gearbox design and development

- Related technology support

- Micro drive gearbox custom solution

Packaging & Shipping

1) Packing Details

packed in nylon firstly, then carton, and then reinforced with wooden case for outer packing.

Or according to client’s requirement.

2) Shipping Details

samples will be shipped within 10 days;

batch order leading time according to the actual situation.

Certifications

Certifications

We Have passed to hold ISO9001:2015(CN11/3571),ISO14001:2004(U006616E0153R3M), ISO13485:2016(CN18/42018) and IATF16949:2016(CN11/3571.01).

and more…

FAQ

FAQ

1. Can you make the gearbox with custom specifications?

YES. We have design and development team, also a great term of engineers, each of them have

many work years experience.

2.Do you provide the samples?

YES. Our company can provide the samples to you, and the delivery time is about 5-15days according to the specification of gearbox you need.

3.What is your MOQ?

Our MOQ is 2000pcs. But at the beginning of our business, we accept small order.

4. Do you have the item in stock?

I am sorry we donot have the item in stock, All products are made with orders.

5. Do you provide technology support?

YES. Our company have design and development team, we can provide technology support if you

need.

6.How to ship to us?

We will ship the goods to you according to the DHL or UPS or FEDEX etc account you provide.

7.How to pay the money?

We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

8. How can I know the product is suitable for me?

Frist, you need to provide us the more details information about the product. We will recommend the item to you according to your requirement of specification. After you confirm, we will prepare the samples to you. also we will offer some good advances according to your product use.

9. Can I come to your company to visit?

YES, you can come to our company to visit at anytime, and welcome to visit our company.

10. How do contact us ?

Please send an inquiry

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial, Household Appliances, Car, Camera |

|---|---|

| Operating Speed: | Low Speed |

| Excitation Mode: | Permanent Magnet |

| Function: | Control |

| Casing Protection: | Drip-Proof |

| Number of Poles: | 2 |

| Samples: |

US$ 90/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are gear motors suitable for both heavy-duty industrial applications and smaller-scale uses?

Yes, gear motors are suitable for both heavy-duty industrial applications and smaller-scale uses. Their versatility and ability to provide torque multiplication make them valuable in a wide range of applications. Here’s a detailed explanation of why gear motors are suitable for both types of applications:

1. Heavy-Duty Industrial Applications:

Gear motors are commonly used in heavy-duty industrial applications due to their robustness and ability to handle high loads. Here are the reasons why they are suitable for such applications:

- Torque Multiplication: Gear motors are designed to provide high torque output, making them ideal for applications that require substantial force to move or operate heavy machinery, conveyors, or equipment.

- Load Handling: Industrial settings often involve heavy loads and demanding operating conditions. Gear motors, with their ability to handle high loads, are well-suited for tasks such as lifting, pulling, pushing, or driving heavy materials or equipment.

- Durability: Heavy-duty industrial applications require components that can withstand harsh environments, frequent use, and demanding operating conditions. Gear motors are typically constructed with durable materials and designed to withstand heavy vibrations, shock loads, and temperature variations.

- Speed Reduction: Many industrial processes require the reduction of motor speed to achieve the desired output speed. Gear motors offer precise speed reduction capabilities through gear ratios, allowing for optimal control and operation of machinery and equipment.

2. Smaller-Scale Uses:

While gear motors excel in heavy-duty industrial applications, they are also suitable for smaller-scale uses across various industries and applications. Here’s why gear motors are well-suited for smaller-scale uses:

- Compact Size: Gear motors are available in compact sizes, making them suitable for applications with limited space or small-scale machinery, devices, or appliances.

- Torque and Power Control: Even in smaller-scale applications, there may be a need for torque multiplication or precise power control. Gear motors can provide the necessary torque and power output for tasks such as precise positioning, controlling speed, or driving small loads.

- Versatility: Gear motors come in various configurations, such as parallel shaft, planetary, or worm gear designs, offering flexibility to match specific requirements. They can be adapted to different applications, including robotics, medical devices, automotive systems, home automation, and more.

- Efficiency: Gear motors are designed to be efficient, converting the electrical input power into mechanical output power with minimal losses. This efficiency is advantageous for smaller-scale applications where energy conservation and battery life are critical.

Overall, gear motors are highly versatile and suitable for both heavy-duty industrial applications and smaller-scale uses. Their ability to provide torque multiplication, handle high loads, offer precise speed control, and accommodate various sizes and configurations makes them a reliable choice in a wide range of applications. Whether it’s powering large industrial machinery or driving small-scale automation systems, gear motors provide the necessary torque, control, and durability required for efficient operation.

Are there environmental benefits to using gear motors in certain applications?

Yes, there are several environmental benefits associated with the use of gear motors in certain applications. Gear motors offer advantages that can contribute to increased energy efficiency, reduced resource consumption, and lower environmental impact. Here’s a detailed explanation of the environmental benefits of using gear motors:

1. Energy Efficiency:

Gear motors can improve energy efficiency in various ways:

- Torque Conversion: Gear reduction allows gear motors to deliver higher torque output while operating at lower speeds. This enables the motor to perform tasks that require high torque, such as lifting heavy loads or driving machinery with high inertia, more efficiently. By matching the motor’s power characteristics to the load requirements, gear motors can operate closer to their peak efficiency, minimizing energy waste.

- Controlled Speed: Gear reduction provides finer control over the motor’s rotational speed. This allows for more precise speed regulation, reducing the likelihood of energy overconsumption and optimizing energy usage.

2. Reduced Resource Consumption:

The use of gear motors can lead to reduced resource consumption and environmental impact:

- Smaller Motor Size: Gear reduction allows gear motors to deliver higher torque with smaller, more compact motors. This reduction in motor size translates to reduced material and resource requirements during manufacturing. It also enables the use of smaller and lighter equipment, which can contribute to energy savings during operation and transportation.

- Extended Motor Lifespan: The gear mechanism in gear motors helps reduce the load and stress on the motor itself. By distributing the load more evenly, gear motors can help extend the lifespan of the motor, reducing the need for frequent replacements and the associated resource consumption.

3. Noise Reduction:

Gear motors can contribute to a quieter and more environmentally friendly working environment:

- Noise Dampening: Gear reduction can help reduce the noise generated by the motor. The gear mechanism acts as a noise dampener, absorbing and dispersing vibrations and reducing overall noise emission. This is particularly beneficial in applications where noise reduction is important, such as residential areas, offices, or noise-sensitive environments.

4. Precision and Control:

Gear motors offer enhanced precision and control, which can lead to environmental benefits:

- Precise Positioning: Gear motors, especially stepper motors and servo motors, provide precise positioning capabilities. This accuracy allows for more efficient use of resources, minimizing waste and optimizing the performance of machinery or systems.

- Optimized Control: Gear motors enable precise control over speed, torque, and movement. This control allows for better optimization of processes, reducing energy consumption and minimizing unnecessary wear and tear on equipment.

In summary, using gear motors in certain applications can have significant environmental benefits. Gear motors offer improved energy efficiency, reduced resource consumption, noise reduction, and enhanced precision and control. These advantages contribute to lower energy consumption, reduced environmental impact, and a more sustainable approach to power transmission and control. When selecting motor systems for specific applications, considering the environmental benefits of gear motors can help promote energy efficiency and sustainability.

Are there specific considerations for selecting the right gear motor for a particular application?

When selecting a gear motor for a specific application, several considerations need to be taken into account. The choice of the right gear motor is crucial to ensure optimal performance, efficiency, and reliability. Here’s a detailed explanation of the specific considerations for selecting the right gear motor for a particular application:

1. Torque Requirement:

The torque requirement of the application is a critical factor in gear motor selection. Determine the maximum torque that the gear motor needs to deliver to perform the required tasks. Consider both the starting torque (the torque required to initiate motion) and the operating torque (the torque required to sustain motion). Select a gear motor that can provide adequate torque to handle the load requirements of the application. It’s important to account for any potential torque spikes or variations during operation.

2. Speed Requirement:

Consider the desired speed range or specific speed requirements of the application. Determine the rotational speed (in RPM) that the gear motor needs to achieve to meet the application’s performance criteria. Select a gear motor with a suitable gear ratio that can achieve the desired speed at the output shaft. Ensure that the gear motor can maintain the required speed consistently and accurately throughout the operation.

3. Duty Cycle:

Evaluate the duty cycle of the application, which refers to the ratio of operating time to rest or idle time. Consider whether the application requires continuous operation or intermittent operation. Determine the duty cycle’s impact on the gear motor, including factors such as heat generation, cooling requirements, and potential wear and tear. Select a gear motor that is designed to handle the expected duty cycle and ensure long-term reliability and durability.

4. Environmental Factors:

Take into account the environmental conditions in which the gear motor will operate. Consider factors such as temperature extremes, humidity, dust, vibrations, and exposure to chemicals or corrosive substances. Choose a gear motor that is specifically designed to withstand and perform optimally under the anticipated environmental conditions. This may involve selecting gear motors with appropriate sealing, protective coatings, or materials that can resist corrosion and withstand harsh environments.

5. Efficiency and Power Requirements:

Consider the desired efficiency and power consumption of the gear motor. Evaluate the power supply available for the application and select a gear motor that operates within the specified voltage and current ranges. Assess the gear motor’s efficiency to ensure that it maximizes power transmission and minimizes wasted energy. Choosing an efficient gear motor can contribute to cost savings and reduced environmental impact.

6. Physical Constraints:

Assess the physical constraints of the application, including space limitations, mounting options, and integration requirements. Consider the size, dimensions, and weight of the gear motor to ensure it can be accommodated within the available space. Evaluate the mounting options and compatibility with the application’s mechanical structure. Additionally, consider any specific integration requirements, such as shaft dimensions, connectors, or interfaces that need to align with the application’s design.

7. Noise and Vibration:

Depending on the application, noise and vibration levels may be critical factors. Evaluate the acceptable noise and vibration levels for the application’s environment and operation. Choose a gear motor that is designed to minimize noise and vibration, such as those with helical gears or precision engineering. This is particularly important in applications that require quiet operation or where excessive noise and vibration may cause issues or discomfort.

By considering these specific factors when selecting a gear motor for a particular application, you can ensure that the chosen gear motor meets the performance requirements, operates efficiently, and provides reliable and consistent power transmission. It’s important to consult with gear motor manufacturers or experts to determine the most suitable gear motor based on the specific application’s needs.

editor by CX 2024-04-22

China OEM Custom 3mm 4mm 12mm 22mm 24mm 37mm 38mm 3V 0.1W DC Geared Motor with Gearbox Motor vacuum pump design

Product Description

Product Description

Model: ZWBMD571571-711

Rated Voltage: 3V

No Load Speed: 26rpm

No load current: 40mA

Rated Speed: 22rpm

Rated Current: 100mA

Rated Torque: 296.9g.cm

Overall Length : 30.9mm

Rated Torque of Gear Box: 330g.cm

Instant Torque of Gear Box: 800g.cm

Gear Ratio: 711:1

Gear Box Length: 16.9mm

Specifications:

| Model | Application Parameters | Rated Torque of Gear Box | Instant Torque of Gear Box | Gear Ratio | Gear Box Length L1 |

|||||||

| Rated | At No Load | At Rated Load | Overall Length L |

|||||||||

| Voltage | Speed | Current | Speed | Current | Torque | |||||||

| VDC | rpm | mA | rpm | mA | gf.cm | mN.m | mm | gf.cm | gf.cm | mm | ||

| ZWBMD006006-110 | 3.0 | 166 | 37 | 140 | 100 | 54.3 | 5.33 | 28.5 | 330 | 800 | 110.6 | 14.5 |

| ZWBMD006006-148 | 3.0 | 124 | 37 | 105 | 100 | 72.8 | 7.14 | 28.5 | 330 | 800 | 148.1 | 14.5 |

| ZWBMD006006-198 | 3.0 | 93 | 37 | 78 | 100 | 97.5 | 9.56 | 28.5 | 330 | 800 | 198.4 | 14.5 |

| ZWBMD006006-266 | 3.0 | 69 | 37 | 58 | 100 | 130.5 | 12.80 | 28.5 | 330 | 800 | 265.7 | 14.5 |

| ZWBMD006006-531 | 3.0 | 35 | 40 | 29 | 100 | 221.7 | 21.74 | 30.9 | 330 | 800 | 530.8 | 16.9 |

| ZWBMD006006-711 | 3.0 | 26 | 40 | 21 | 100 | 296.9 | 29.12 | 30.9 | 330 | 800 | 711.0 | 16.9 |

| ZWBMD006006-952 | 3.0 | 19 | 40 | 16 | 95 | 330 | 32.36 | 30.9 | 330 | 800 | 952.2 | 16.9 |

| ZWBMD006006-1275 | 3.0 | 14 | 40 | 12 | 85 | 330 | 32.36 | 30.9 | 330 | 800 | 1275.2 | 16.9 |

| ZWBMD006006-1708 | 3.0 | 11 | 40 | 10 | 75 | 330 | 32.36 | 30.9 | 330 | 800 | 1707.9 | 16.9 |

above specifications just for reference and customizable according to requirements.

Please let us know your requirements and we will provide you with micro transmission solutions.

2D Drawing

Detailed Photos

Application

| Smart wearable devices | watch,VR,AR,XR and etc. |

| Household application | kitchen appliances, sewing machines, corn popper, vacuum cleaner, garden tool, sanitary ware, window curtain, intelligent closestool, sweeping robot, power seat, standing desk, electric sofa, TV, computer, treadmill, spyhole, cooker hood, electric drawer, electric mosquito net, intelligent cupboard, intelligent wardrobe, automatic soap dispenser, UV baby bottle sterilizer, lifting hot pot cookware, dishwasher, washing machine, food breaking machine, dryer, air conditioning, dustbin, coffee machine, whisk,smart lock,bread maker,Window cleaning robot and etc. |

| communication equipment | 5G base station,video conference,mobile phone and etc. |

| Office automation equipments | scanners, printers, multifunction machines copy machines, fax (FAX paper cutter), computer peripheral, bank machine, screen, lifting socket, display,notebook PC and etc. |

| Automotive products | conditioning damper actuator, car DVD,door lock actuator, retractable rearview mirror, meters, optic axis control device, head light beam level adjuster, car water pump, car antenna, lumbar support, EPB, car tail gate electric putter, HUD, head-up display, vehicle sunroof, EPS, AGS, car window, head restraint, E-booster, car seat, vehicle charging station and etc. |

| Toys and models | radio control model, automatic cruise control, ride-on toy, educational robot, programming robot, medical robot, automatic feeder, intelligent building blocks, escort robot and etc. |

| Medical equipments | blood pressure meter, breath machine, medical cleaning pump, medical bed, blood pressure monitors, medical ventilator, surgical staplers, infusion pump, dental instrument, self-clotting cutter, wound cleaning pump for orthopedic surgery,electronic cigarette, eyebrow pencil,fascia gun, , surgical robot,laboratory automation and etc. |

| Industrials | flow control valves, seismic testing,automatic reclosing,Agricultural unmanned aerial vehicle,automatic feeder ,intelligent express cabinet and etc. |

| Electric power tools | electric drill, screwdriver,garden tool and etc. |

| Precision instruments | optics instruments,automatic vending machine, wire-stripping machine and etc. |

| Personal care | tooth brush, hair clipper, electric shaver, massager, vibrator, hair dryer, rubdown machine, scissor hair machine, foot grinder,anti-myopia pen, facial beauty equipment, hair curler,Electric threading knife,POWER PERFECT PORE, Puff machine,eyebrow tweezers and etc. |

| Consumer electronics | camera, mobile phone,digital camera, automatic retracting device,camcorder, kinescope DVD,headphone stereo, cassette tape recorder, bluetooth earbud charging case, turntable, tablet,UAV(unmanned aerial vehicle),surveillance camera,PTZ camera, rotating smart speaker and etc. |

| robots | educational robot, programming robot, medical robot, escort robot and etc. |

Company Profile

HangZhou CHINAMFG Machinery & Electronics Co., Ltd was established in 2001,We provide the total drive solution for customers from design, tooling fabrication, components manufacturing and assembly.

Workshop

Testing Equipment

1) Competitive Advantages

- 1) Competitive Advantages

19+year experience in manufacturing motor gearbox

We provide technical support from r&d, prototype, testing, assembly and serial production , ODM &OEM

Competitive Price

Product Performance: Low noise, High efficiency, Long lifespan

Prompt Delivery: 15 working days after payment

Small Orders Accepted

2) Main Products

-

Precision reduction gearbox and its diameter:3.4mm-38mm,voltage:1.5-24V,power: 0.01-40W,output speed:5-2000rpm and output torque:1.0 gf.cm -50kgf.cm,

- Customized worm and gear transmission machinery;

- Precise electromechanical motion module;

- Precise component and assembly of plastic and metal powder injection.

Our Services

- ODM & OEM

- Gearbox design and development

- Related technology support

- Micro drive gearbox custom solution

Packaging & Shipping

1) Packing Details

packed in nylon firstly, then carton, and then reinforced with wooden case for outer packing.

Or according to client’s requirement.

2) Shipping Details

samples will be shipped within 10 days;

batch order leading time according to the actual situation.

Certifications

Certifications

We Have passed to hold ISO9001:2015(CN11/3571),ISO14001:2004(U006616E0153R3M), ISO13485:2016(CN18/42018) and IATF16949:2016(CN11/3571.01).

and more…

FAQ

FAQ

1. Can you make the gearbox with custom specifications?

YES. We have design and development team, also a great term of engineers, each of them have

many work years experience.

2.Do you provide the samples?

YES. Our company can provide the samples to you, and the delivery time is about 5-15days according to the specification of gearbox you need.

3.What is your MOQ?

Our MOQ is 2000pcs. But at the beginning of our business, we accept small order.

4. Do you have the item in stock?

I am sorry we donot have the item in stock, All products are made with orders.

5. Do you provide technology support?

YES. Our company have design and development team, we can provide technology support if you

need.

6.How to ship to us?

We will ship the goods to you according to the DHL or UPS or FEDEX etc account you provide.

7.How to pay the money?

We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

8. How can I know the product is suitable for me?

Frist, you need to provide us the more details information about the product. We will recommend the item to you according to your requirement of specification. After you confirm, we will prepare the samples to you. also we will offer some good advances according to your product use.

9. Can I come to your company to visit?

YES, you can come to our company to visit at anytime, and welcome to visit our company.

10. How do contact us ?

Please send an inquiry

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Universal, Industrial, Household Appliances, Car, Camera |

|---|---|

| Operating Speed: | Low Speed |

| Excitation Mode: | Permanent Magnet |

| Function: | Control |

| Casing Protection: | Drip-Proof |

| Number of Poles: | 2 |

| Samples: |

US$ 90/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are there innovations or emerging technologies in the field of gear motor design?

Yes, there are several innovations and emerging technologies in the field of gear motor design. These advancements aim to improve the performance, efficiency, compactness, and reliability of gear motors. Here are some notable innovations and emerging technologies in gear motor design:

1. Miniaturization and Compact Design:

Advancements in manufacturing techniques and materials have enabled the miniaturization of gear motors without compromising their performance. Gear motors with compact designs are highly sought after in applications where space is limited, such as robotics, medical devices, and consumer electronics. Innovative approaches like micro-gear motors and integrated motor-gear units are being developed to achieve smaller form factors while maintaining high torque and efficiency.

2. High-Efficiency Gearing:

New gear designs focus on improving efficiency by reducing friction and mechanical losses. Advanced gear manufacturing techniques, such as precision machining and 3D printing, allow for the creation of intricate gear tooth profiles that optimize power transmission and minimize losses. Additionally, the use of high-performance materials, coatings, and lubricants helps reduce friction and wear, improving overall gear motor efficiency.

3. Magnetic Gearing:

Magnetic gearing is an emerging technology that replaces traditional mechanical gears with magnetic fields to transmit torque. It utilizes the interaction of permanent magnets to transfer power, eliminating the need for physical gear meshing. Magnetic gearing offers advantages such as high efficiency, low noise, compactness, and maintenance-free operation. While still being developed and refined, magnetic gearing holds promise for various applications, including gear motors.

4. Integrated Electronics and Controls:

Gear motor designs are incorporating integrated electronics and controls to enhance performance and functionality. Integrated motor drives and controllers simplify system integration, reduce wiring complexity, and allow for advanced control features. These integrated solutions offer precise speed and torque control, intelligent feedback mechanisms, and connectivity options for seamless integration into automation systems and IoT (Internet of Things) platforms.

5. Smart and Condition Monitoring Capabilities:

New gear motor designs incorporate smart features and condition monitoring capabilities to enable predictive maintenance and optimize performance. Integrated sensors and monitoring systems can detect abnormal operating conditions, track performance parameters, and provide real-time feedback for proactive maintenance and troubleshooting. This helps prevent unexpected failures, extend the lifespan of gear motors, and improve overall system reliability.

6. Energy-Efficient Motor Technologies:

Gear motor design is influenced by advancements in energy-efficient motor technologies. Brushless DC (BLDC) motors and synchronous reluctance motors (SynRM) are gaining popularity due to their higher efficiency, better power density, and improved controllability compared to traditional brushed DC and induction motors. These motor technologies, when combined with optimized gear designs, contribute to overall system energy savings and performance improvements.

These are just a few examples of the innovations and emerging technologies in gear motor design. The field is continuously evolving, driven by the need for more efficient, compact, and reliable motion control solutions in various industries. Gear motor manufacturers and researchers are actively exploring new materials, manufacturing techniques, control strategies, and system integration approaches to meet the evolving demands of modern applications.

Can gear motors be used for precise positioning, and if so, what features enable this?

Yes, gear motors can be used for precise positioning in various applications. The combination of gear mechanisms and motor control features enables gear motors to achieve accurate and repeatable positioning. Here’s a detailed explanation of the features that enable gear motors to be used for precise positioning:

1. Gear Reduction:

One of the key features of gear motors is their ability to provide gear reduction. Gear reduction refers to the process of reducing the output speed of the motor while increasing the torque. By using the appropriate gear ratio, gear motors can achieve finer control over the rotational movement, allowing for more precise positioning. The gear reduction mechanism enables the motor to rotate at a slower speed while maintaining higher torque, resulting in improved accuracy and control.

2. High Resolution Encoders:

Many gear motors are equipped with high-resolution encoders. An encoder is a device that measures the position and speed of the motor shaft. High-resolution encoders provide precise feedback on the motor’s rotational position, allowing for accurate position control. The encoder signals are used in conjunction with motor control algorithms to ensure precise positioning by monitoring and adjusting the motor’s movement in real-time. The use of high-resolution encoders greatly enhances the gear motor’s ability to achieve precise and repeatable positioning.

3. Closed-Loop Control:

Gear motors with closed-loop control systems offer enhanced positioning capabilities. Closed-loop control involves continuously comparing the actual motor position (as measured by the encoder) with the desired position and making adjustments to minimize any position error. The closed-loop control system uses feedback from the encoder to adjust the motor’s speed, direction, and torque, ensuring accurate positioning even in the presence of external disturbances or variations in the load. Closed-loop control enables gear motors to actively correct for position errors and maintain precise positioning over time.

4. Stepper Motors:

Stepper motors are a type of gear motor that provides excellent precision and control for positioning applications. Stepper motors operate by converting electrical pulses into incremental steps of movement. Each step corresponds to a specific angular displacement, allowing precise positioning control. Stepper motors offer high step resolution, allowing for fine position adjustments. They are commonly used in applications that require precise positioning, such as robotics, 3D printers, and CNC machines.

5. Servo Motors:

Servo motors are another type of gear motor that excels in precise positioning tasks. Servo motors combine a motor, a feedback device (such as an encoder), and a closed-loop control system. They offer high torque, high speed, and excellent positional accuracy. Servo motors are capable of dynamically adjusting their speed and torque to maintain the desired position accurately. They are widely used in applications that require precise and responsive positioning, such as industrial automation, robotics, and camera pan-tilt systems.

6. Motion Control Algorithms:

Advanced motion control algorithms play a crucial role in enabling gear motors to achieve precise positioning. These algorithms, implemented in motor control systems or dedicated motion controllers, optimize the motor’s behavior to ensure accurate positioning. They take into account factors such as acceleration, deceleration, velocity profiling, and jerk control to achieve smooth and precise movements. Motion control algorithms enhance the gear motor’s ability to start, stop, and position accurately, reducing position errors and overshoot.

By leveraging gear reduction, high-resolution encoders, closed-loop control, stepper motors, servo motors, and motion control algorithms, gear motors can be effectively used for precise positioning in various applications. These features enable gear motors to achieve accurate and repeatable positioning, making them suitable for tasks that require precise control and reliable positioning performance.

What is a gear motor, and how does it combine the functions of gears and a motor?

A gear motor is a type of motor that incorporates gears into its design to combine the functions of gears and a motor. It consists of a motor, which provides the mechanical power, and a set of gears, which transmit and modify this power to achieve specific output characteristics. Here’s a detailed explanation of what a gear motor is and how it combines the functions of gears and a motor:

A gear motor typically consists of two main components: the motor and the gear system. The motor is responsible for converting electrical energy into mechanical energy, generating rotational motion. The gear system, on the other hand, consists of multiple gears with different sizes and tooth configurations. These gears are meshed together in a specific arrangement to transmit and modify the output torque and speed of the motor.

The gears in a gear motor serve several functions:

1. Torque Amplification:

One of the primary functions of the gear system in a gear motor is to amplify the torque output of the motor. By using gears with different sizes, the input torque can be effectively multiplied or reduced. This allows the gear motor to provide higher torque at lower speeds or lower torque at higher speeds, depending on the gear arrangement. This torque amplification is beneficial in applications where high torque is required, such as in heavy machinery or vehicles.

2. Speed Reduction or Increase:

The gear system in a gear motor can also be used to reduce or increase the rotational speed of the motor output. By utilizing gears with different numbers of teeth, the gear ratio can be adjusted to achieve the desired speed output. For example, a gear motor with a higher gear ratio will output lower speed but higher torque, whereas a gear motor with a lower gear ratio will output higher speed but lower torque. This speed control capability allows for precise matching of motor output to the requirements of specific applications.

3. Directional Control:

Gears in a gear motor can be used to control the direction of rotation of the motor output shaft. By employing different combinations of gears, such as spur gears, bevel gears, or worm gears, the rotational direction can be changed. This directional control is crucial in applications where bidirectional movement is required, such as in conveyor systems or robotic arms.

4. Load Distribution:

The gear system in a gear motor helps distribute the load evenly across multiple gears, which reduces the stress on individual gears and increases the overall durability and lifespan of the motor. By sharing the load among multiple gears, the gear motor can handle higher torque applications without putting excessive strain on any particular gear. This load distribution capability is especially important in heavy-duty applications that require continuous operation under demanding conditions.

By combining the functions of gears and a motor, gear motors offer several advantages. They provide torque amplification, speed control, directional control, and load distribution capabilities, making them suitable for various applications that require precise and controlled mechanical power. Gear motors are commonly used in industries such as robotics, automotive, manufacturing, and automation, where reliable and efficient power transmission is essential.

editor by CX 2024-04-19

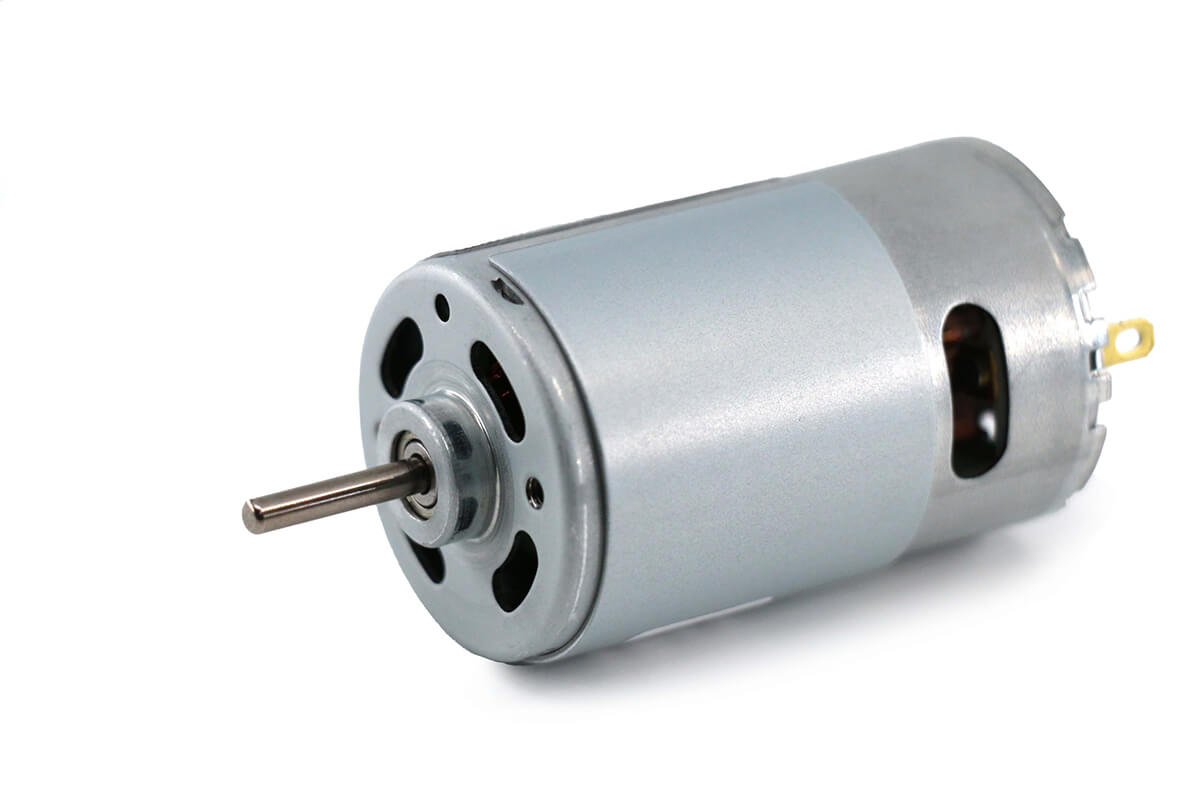

China Professional 12V 24V RS 385s High Speed Micro Hydraulic Motor Planetary Gearbox 5V 6 Volt DC Gear Motor vacuum pump distributors

Product Description

Product Description

Product Description

Company Profile

Company profile

ZheJiang Lulang New Material Technology Co., Ltd headquartered in HangZhou, China, is a high-tech enterprise engaged in the research, development, production and sales of new permanent magnetic materials. As an expert in the application technology of permanent magnetic materials, we have advanced magnetic performance analyzer, professional analytical magnets and experienced senior technical engineers, which can help customers better choose appropriate magnetic materials, and can also customize various magnetic components according to customers’ needs.

Our products and services: Sintered neodymium iron boron series, pressure plastic rubber magnet, high temperature resistant samarium cobalt, sintered ferrite permanent magnet, magnetic components related accessories and mold design and manufacturing; The design, testing and verification of magnetic materials, professional research and development team, meet the customer’s product customization, quality assurance, and a complete range of electroplating supporting equipment (white zinc, color zinc, white nickel, black nickel, organic epoxy resin, electrophoresis, aluminum electroplating, phosphating, etc. )

Exhibition

Exhibition

Payment and logistics

Payment and logistics

FAQ

FAQ

Q1: How long does NdFeB magnet last?

A: Under normal circumstance,magnetic force would not reduce,belong to permanent;high temperature and high pressure will affect magnet performance .

Q2: What are the surface treatments for NdFeB magnets?

A: In general, it is nickel , Zinc and black epoxy plated, we can also customize according to customer needs.

Q3: Could I get samples?How long is the delivery time for samples and bulk order?

A:1.Yes, we have materials in stock to help you to get the samples as soon as we can. 2. If we have materials in our stock, we can send them within 3 working days. If we don’t have material in stock, production timefor sample is 5-10 days, 15-25 days for bulk order.

Q4: How is the quality and price?

A: Our main markets are North America and Europe,Our core competitiveness is high quality, we will provide the high quality magnet with reasonable price.

Q5: What is the magnets application ?

A: Neodymium magnet have been growing rapidly in the global market, magnets are widely used in the :Computers, Copiers, Wind power stations, Electron spin resonance, dental material.industrial robots, Recycling,Television,speakers, Motor, Sensors. Mobile, Cars, information technologies, etc. Motors, Medical Equipment and so on.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industrial Magnet |

|---|---|

| Shape: | Customized |

| Coating: | Nickel |

| Samples: |

US$ 10.00/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the speed control of a DC motor work, and what methods are commonly employed?

The speed control of a DC (Direct Current) motor is essential for achieving precise control over its rotational speed. Various methods can be employed to regulate the speed of a DC motor, depending on the specific application requirements. Here’s a detailed explanation of how speed control of a DC motor works and the commonly employed methods:

1. Voltage Control:

One of the simplest methods to control the speed of a DC motor is by varying the applied voltage. By adjusting the voltage supplied to the motor, the electromotive force (EMF) induced in the armature windings can be controlled. According to the principle of electromagnetic induction, the speed of the motor is inversely proportional to the applied voltage. Therefore, reducing the voltage decreases the speed, while increasing the voltage increases the speed. This method is commonly used in applications where a simple and inexpensive speed control mechanism is required.

2. Armature Resistance Control:

Another method to control the speed of a DC motor is by varying the armature resistance. By inserting an external resistance in series with the armature windings, the total resistance in the circuit increases. This increase in resistance reduces the armature current, thereby reducing the motor’s speed. Conversely, reducing the resistance increases the armature current and the motor’s speed. However, this method results in significant power loss and reduced motor efficiency due to the dissipation of excess energy as heat in the external resistance.

3. Field Flux Control:

Speed control can also be achieved by controlling the magnetic field strength of the motor’s stator. By altering the field flux, the interaction between the armature current and the magnetic field changes, affecting the motor’s speed. This method can be accomplished by adjusting the field current through the field windings using a field rheostat or by employing a separate power supply for the field windings. By increasing or decreasing the field flux, the speed of the motor can be adjusted accordingly. This method offers good speed regulation and efficiency but requires additional control circuitry.

4. Pulse Width Modulation (PWM):

Pulse Width Modulation is a widely used technique for speed control in DC motors. It involves rapidly switching the applied voltage on and off at a high frequency. The duty cycle, which represents the percentage of time the voltage is on, is varied to control the effective voltage applied to the motor. By adjusting the duty cycle, the average voltage across the motor is modified, thereby controlling its speed. PWM provides precise speed control, high efficiency, and low power dissipation. It is commonly employed in applications such as robotics, industrial automation, and electric vehicles.

5. Closed-Loop Control:

In closed-loop control systems, feedback from the motor’s speed or other relevant parameters is used to regulate the speed. Sensors such as encoders or tachometers measure the motor’s actual speed, which is compared to the desired speed. The difference, known as the error signal, is fed into a control algorithm that adjusts the motor’s input voltage or other control parameters to minimize the error and maintain the desired speed. Closed-loop control provides excellent speed regulation and accuracy, making it suitable for applications that require precise speed control, such as robotics and CNC machines.

These methods of speed control provide flexibility and adaptability to various applications, allowing DC motors to be effectively utilized in a wide range of industries and systems.

Are there specific types of DC motors designed for different industries or applications?

Yes, there are specific types of DC (Direct Current) motors that are designed and optimized for various industries and applications. DC motors offer a wide range of performance characteristics, allowing them to be tailored to specific requirements. Here’s a detailed explanation of the types of DC motors designed for different industries or applications:

1. Brushed DC Motors:

Brushed DC motors are commonly used in applications that require simple and cost-effective motor solutions. They are suitable for applications with lower efficiency requirements and where maintenance considerations are manageable. Some common industries and applications that use brushed DC motors include:

- Automotive: Power window mechanisms, windshield wipers, cooling fans, and seat adjustment systems.

- Consumer Electronics: Household appliances, toys, power tools, and personal care devices.

- Industrial Machinery: Conveyors, pumps, fans, and machine tools.

2. Brushless DC Motors:

Brushless DC motors are known for their higher efficiency, greater reliability, and precise control capabilities. They are widely used in industries and applications that demand higher performance and advanced control features. Some specific industries and applications that utilize brushless DC motors include:

- Automotive: Electric power steering systems, electric vehicles, hybrid vehicles, and HVAC systems.

- Aerospace and Defense: Actuators, robotics, unmanned aerial vehicles (UAVs), and missile systems.

- Medical and Laboratory Equipment: Centrifuges, pumps, robotics, and diagnostic devices.

- Industrial Automation: CNC machines, robotics, automated guided vehicles (AGVs), and precision motion control systems.

- Renewable Energy: Wind turbine generators, solar tracking systems, and energy storage systems.

3. High-Torque DC Motors:

High-torque DC motors are designed to provide substantial torque output at low speeds. They are commonly used in applications that require heavy lifting or high starting torque. Industries and applications that often utilize high-torque DC motors include:

- Material Handling: Cranes, hoists, winches, lifts, and elevators.

- Construction and Mining: Excavators, bulldozers, drilling rigs, and conveyor systems.

- Automotive: Electric vehicles, electric powertrains, and traction control systems.

- Marine and Shipbuilding: Thrusters, winches, and anchor handling systems.

4. Low-Voltage DC Motors:

Low-voltage DC motors are designed to operate at lower voltages, typically below 24 volts. They are commonly used in battery-powered applications and systems where safety or specific voltage requirements exist. Some industries and applications that utilize low-voltage DC motors include:

- Automotive: Automotive accessories, window actuators, and door locks.

- Robotics and Hobbyist Projects: DIY robots, RC vehicles, and model trains.

- Solar Power Systems: Solar tracking systems, solar panel actuators, and solar-powered water pumps.

- Home Automation: Automated blinds, curtains, and smart home devices.

These are just a few examples of the types of DC motors designed for different industries and applications. The versatility and adaptability of DC motors make them suitable for a wide range of uses, and manufacturers often offer customized motor solutions to meet specific requirements.

Are there innovations or emerging technologies in the field of DC motor design?

Yes, there have been several innovations and emerging technologies in the field of DC (Direct Current) motor design. These advancements aim to improve the performance, efficiency, reliability, and overall capabilities of DC motors. Here’s a detailed explanation of some notable innovations and emerging technologies in DC motor design:

1. Brushless DC Motors:

One significant advancement in DC motor design is the development and widespread adoption of brushless DC motors (BLDC motors). Unlike traditional DC motors that use brushes for commutation, BLDC motors employ electronic commutation through the use of permanent magnets and motor controller circuits. This eliminates the need for brushes, reducing maintenance requirements and improving overall motor efficiency and lifespan. BLDC motors offer higher torque density, smoother operation, better speed control, and improved energy efficiency compared to conventional brushed DC motors.

2. High-Efficiency Materials:

The use of high-efficiency materials in DC motor design has been an area of focus for improving motor performance. Advanced magnetic materials, such as neodymium magnets, have allowed for stronger and more compact motor designs. These materials increase the motor’s power density, enabling higher torque output and improved efficiency. Additionally, advancements in materials used for motor windings and core laminations have reduced electrical losses and improved overall motor efficiency.

3. Power Electronics and Motor Controllers:

Advancements in power electronics and motor control technologies have greatly influenced DC motor design. The development of sophisticated motor controllers and efficient power electronic devices enables precise control of motor speed, torque, and direction. These technologies have resulted in more efficient and reliable motor operation, reduced energy consumption, and enhanced motor performance in various applications.

4. Integrated Motor Systems:

Integrated motor systems combine the motor, motor controller, and associated electronics into a single unit. These integrated systems offer compact designs, simplified installation, and improved overall performance. By integrating the motor and controller, issues related to compatibility and communication between separate components are minimized. Integrated motor systems are commonly used in applications such as robotics, electric vehicles, and industrial automation.

5. IoT and Connectivity:

The integration of DC motors with Internet of Things (IoT) technologies and connectivity has opened up new possibilities for monitoring, control, and optimization of motor performance. By incorporating sensors, actuators, and connectivity features, DC motors can be remotely monitored, diagnosed, and controlled. This enables predictive maintenance, energy optimization, and real-time performance adjustments, leading to improved efficiency and reliability in various applications.

6. Advanced Motor Control Algorithms:

Advanced motor control algorithms, such as sensorless control and field-oriented control (FOC), have contributed to improved performance and efficiency of DC motors. Sensorless control techniques eliminate the need for additional sensors by leveraging motor current and voltage measurements to estimate rotor position. FOC algorithms optimize motor control by aligning the magnetic field with the rotor position, resulting in improved torque and efficiency, especially at low speeds.

These innovations and emerging technologies in DC motor design have revolutionized the capabilities and performance of DC motors. Brushless DC motors, high-efficiency materials, advanced motor control techniques, integrated motor systems, IoT connectivity, and advanced control algorithms have collectively contributed to more efficient, reliable, and versatile DC motor solutions across various industries and applications.

editor by CX 2024-04-17

China wholesaler Input Extension Shaft Speed Reduction DC Electric Motor in Mechanica Gearbox vacuum pump ac system

Product Description

Characteristics:

(1)Large output torque

(2) Safe, reliable, economical and durable

(3) Stable transmission, quiet operation

(4) High heat-radiating efficiency, high carrying ability

(5) Combination of 2 single-step worm gear speed reducers, meeting the requirements of super speed ratio

(6) Mechanical gearboxes are widely used in the sectors,like foodstuff, ceramics, and chemical manufacturing, as well as packing, printing, dyeing and plastics

Technical data:

(1) Motor input power:0.06kw-15kw

(2) Output torque:4-2320N.M

(3) Speed ratio of worm gear peed reducer: 5/10/15/20/25/30/40/50/60/80/100

(4) With IEC motor input flange: 56B14/71B14/80B5/90B5…

Materials:

(1) NMRV571-NMRV090: Aluminium alloy housing

(2) NMRV110-150: Cast iron housing

(3) Bearing: CHINAMFG bearing & Homemade bearing

(4) Lubricant: Synthetic & Mineral

(5) The material of the worm mandrel is HT250, and the worm ring gear is ZQSn10-1.

(6) With high quality homemade bearings, assembled CHINAMFG oil seals & filled with high quality lubricant.

Operation&mantenance

(1)When worm speed reducer starts to work up to200-400 hours, its lubricant should be replaced.

(2)The gearbox need to replace the oil after 4000 hours.

(3)Worm reduction gearbox is fully filled with lubricant oil after finshed assembly.

(4)Lubricanting oil should be kept enough in the casing and checked at a fixed time.

Color:

(1) Blue / Light blue

(2) Silvery White

Quality control

(1) Quality guarantee: 1 year

(2) Certificate of quality: ISO9001:2000

(3) Every product must be tested before sending

| Motor power | Model | speed ratio | output speed | output toruqe |

| 0.06kw 1400rpm | NMRV030 | 5 | 280rpm | 2.0N.M |

| NMRV030 | 7.5 | 186rpm | 2.6N.M | |

| NMRV030 | 10 | 140rpm | 3.3N.M | |

| NMRV030 | 15 | 94rpm | 4.7N.M | |

| NMRV030 | 20 | 70rpm | 5.9N.M | |

| NMRV030 | 25 | 56rpm | 6.8N.M | |

| NMRV030 | 30 | 47rpm | 7.9N.M | |

| NMRV030 | 40 | 35rpm | 9.7N.M | |

| NMRV030 | 50 | 28rpm | 11.0N.M | |

| NMRV030 | 60 | 24rpm | 12.0N.M | |

| NMRV030 | 80 | 18rpm | 14.0N.M | |

| 0.09kw 1400rpm | NMRV030 | 5 | 280rpm | 2.7N.M |

| NMRV030 | 7.5 | 186rpm | 3.9N.M | |

| NMRV030 | 10 | 140rpm | 5.0N.M | |

| NMRV030 | 15 | 94rpm | 7.0N.M | |

| NMRV030 | 20 | 70rpm | 8.8N.M | |

| NMRV030 | 25 | 56rpm | 10.0N.M | |

| NMRV030 | 30 | 47rpm | 12.0N.M | |

| NMRV030 | 40 | 35rpm | 14.0N.M | |

| NMRV030 | 50 | 28rpm | 17.0N.M | |

| NMRV030 | 60 | 24rpm | 18.0N.M | |

| 0.12kw 1400rpm | NMRV030 | 5 | 280rpm | 3.6N.M |

| NMRV030 | 7.5 | 186rpm | 5.2N.M | |

| NMRV030 | 10 | 140rpm | 6.6N.M | |

| NMRV030 | 15 | 94rpm | 9.3N.M | |

| NMRV030 | 20 | 70rpm | 12.0N.M | |

| NMRV030 | 25 | 56rpm | 14.0N.M | |

| NMRV030 | 30 | 47rpm | 16.0N.M | |

| NMRV030 | 40 | 35rpm | 19.0N.M | |

| NMRV030 | 50 | 28rpm | 22.0N.M | |

| 0.18kw 1400rpm | NMRV030 | 5 | 280rpm | 5.3N.M |

| NMRV030 | 7.5 | 186rpm | 7.7N.M | |

| NMRV030 | 10 | 140rpm | 10.0N.M | |

| NMRV030 | 15 | 94rpm | 14.0N.M | |

| NMRV030 | 20 | 70rpm | 18.0N.M | |

| NMRV030 | 25 | 56rpm | 20.0N.M | |

| NMRV030 | 30 | 47rpm | 24.0N.M |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Reducer |

|---|---|

| Operating Speed: | High Speed |

| Excitation Mode: | Excited |

| Function: | Control |

| Casing Protection: | Open Type |

| Number of Poles: | 6 |

| Customization: |

Available

|

|

|---|

What are the key differences between brushed and brushless DC motors?

Brushed and brushless DC motors are two distinct types of motors that differ in their construction, operation, and performance characteristics. Here’s a detailed explanation of the key differences between brushed and brushless DC motors:

1. Construction:

Brushed DC Motors: Brushed DC motors have a relatively simple construction. They consist of a rotor with armature windings and a commutator, and a stator with permanent magnets or electromagnets. The commutator and brushes make physical contact to provide electrical connections to the armature windings.

Brushless DC Motors: Brushless DC motors have a more complex construction. They typically consist of a stationary stator with permanent magnets or electromagnets and a rotor with multiple coils or windings. The rotor does not have a commutator or brushes.

2. Commutation:

Brushed DC Motors: In brushed DC motors, the commutator and brushes are responsible for the commutation process. The brushes make contact with different segments of the commutator, reversing the direction of the current through the armature windings as the rotor rotates. This switching of the current direction generates the necessary torque for motor rotation.