Product Description

Product Description

Model selection

1.Installation method: Horizontal ( foot) installation, Vertical ( flange) installation

2.Requirement for the output shaft of motor: 18,22,28,32,40,50mm

3.Power requirement: 100W, 200W….3700W

4.Speed of the motor you need

5.Ratio: Motor input speed/output speed. Or advise your required output speed. We have 3,5,10…1800

6.Voltage: Three phase 220V/380V 50/60Hz; Single phase 110, 220V 50/60Hz

7.Additional parts:DC 90V brake unit; Hand release brake unit; DC 24V brake unit, 110V forced draft fan; 220V forced draft fan.

8.Position of terminal box: view from output shaft

9.Wire inlet direction

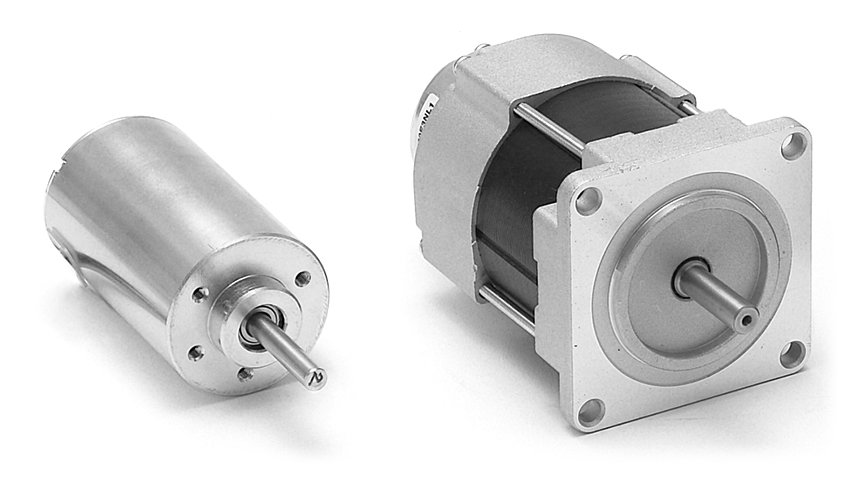

Features of AC Gear motor

1.Small size, light weight, knot no noise, compact, maintenance-free

2.High tightness. Geared motor output section has the configuration of seals and O-ring to avoid grease refluxing and damage of insulation aging .

3.High efficiency. The gear motor products using the new silicon steel stamping die design, high precision core, strong magnetic properties, geared motor cooling structure using the new shape .

4.Optimal design, the ST ( speed – torque ) features optimized so that gear motors can work for a variety of operating environments.

5.Customized, our company has developed its own design team, geared motors can be customized according to the customer ‘s specific needs specifications.

Application:

Various industrial production lines, coveyor machinery, food machinery, medical machinery, printing machinery, office facility, instrument, automatic mahjong machine

| 1/8hp-100w | 1/4hp-200w | 1/2hp-400w | 1hp-750w | 2hp-1.5kw | 3hp-2.2kw | 5hp-3.7kw | ||||||||||||||

| Type | Indicated Odds |

Actual odds |

Type | Indicated Odds |

Actual odds |

Type | Indicated Odds |

Actual odds |

Type | Indicated Odds |

Actual odds |

Type | Indicated Odds |

Actual odds |

Type | Indicated Odds |

Actual odds |

Type | Indicated Odds |

Actual odds |

| 18 | 5 | 4.58 | 18 | 5 | 6.82 | 22 | 5 | 5.218 | 28 | 5 | 5.745 | 32 | 5 | 5.01 | 32 | 5 | 5.01 | 40 | 5 | 5.1 |

| 10 | 10 | 10 | 10.3 | 10 | 9.97 | 10 | 11.157 | 10 | 10.08 | 10 | 10.08 | 10 | 9.87 | |||||||

| 15 | 15.1 | 15 | 16.67 | 15 | 13.73 | 15 | 16.157 | 15 | 16.2 | 40 | 15 | 17.03 | 15 | 17.03 | ||||||

| 20 | 19.9 | 20 | 21 | 20 | 20.01 | 20 | 19.942 | 20 | 19.6 | 20 | 21.33 | 20 | 21.33 | |||||||

| 25 | 24.44 | 25 | 28.3 | 25 | 25.04 | 25 | 24.704 | 25 | 25.07 | 25 | 24.19 | 50 | 25 | 24.88 | ||||||

| 30 | 30.8 | 22 | 15 | 15.46 | 28 | 15 | 14.75 | 32 | 30 | 31.09 | 40 | 30 | 30.44 | 30 | 30.44 | 30 | 29.85 | |||

| 40 | 41.25 | 20 | 20.34 | 20 | 21.16 | 35 | 35.82 | 40 | 42.79 | 40 | 37.52 | 35 | 36.05 | |||||||

| 50 | 48.19 | 25 | 25.09 | 25 | 26.11 | 40 | 41.28 | 50 | 52.52 | 50 | 52.52 | 40 | 40.67 | |||||||

| 22 | 60 | 30 | 28.18 | 30 | 29.33 | 50 | 51.06 | 60 | 58.54 | 60 | 58.54 | 45 | 46.33 | |||||||

| 70 | 35 | 36.66 | 40 | 41.11 | 60 | 57.6 | 70 | 72.16 | 50 | 70 | 68.63 | 50 | 49.63 | |||||||

| 95 | 40 | 42.72 | 55 | 46.3 | 70 | 70.9 | 80 | 81.06 | 80 | 82.95 | 60 | 59.56 | ||||||||

| 105 | 50 | 50.23 | 50 | 50.35 | 80 | 78 | 90 | 91.93 | 90 | 90.67 | 70 | 69.69 | ||||||||

| 120 | 65 | 66.12 | 55 | 56.28 | 90 | 92.57 | 105 | 104.83 | 100 | 99.55 | 80 | 81.89 | ||||||||

| 130 | 75 | 73.2 | 65 | 63.38 | 100 | 101.23 | 50 | 110 | 109.93 | 110 | 109.93 | |||||||||

| 170 | 80 | 81.55 | 75 | 72.27 | 110 | 112.01 | 120 | 121.31 | 120 | 121.31 | ||||||||||

| 200 | 90 | 91.57 | 80 | 80.77 | 125 | 124.49 | 125 | 125.18 | 140 | 137.24 | ||||||||||

| 18 | 100 | 100.38 | 90 | 89.2 | 130 | 128.68 | 140 | 137.24 | 160 | 155.91 | ||||||||||

| 110 | 112.16 | 100 | 100.2 | 140 | 139.85 | 155 | 155.91 | 180 | 1766.38 | |||||||||||

| 125 | 125.99 | 150 | 147.73 | 180 | 176.38 | |||||||||||||||

| 140 | 141.9 | 160 | 159.46 | |||||||||||||||||

| 165 | 164.05 | 32 | 100 | 101.1 | 180 | 180.86 | ||||||||||||||

| 185 | 184.77 | 110 | 108.44 | 40 | 125 | 125.23 | ||||||||||||||

| 120 | 119.98 | 135 | 133.76 | |||||||||||||||||

| 130 | 131.21 | 150 | 150.46 | |||||||||||||||||

| 145 | 145.69 | 160 | 160.7 | |||||||||||||||||

| 150 | 149.98 | 180 | 179.97 | |||||||||||||||||

| 160 | 161.2 | 200 | 216.22 | |||||||||||||||||

| 180 | 181.48 | |||||||||||||||||||

| 200 | 201.5 | |||||||||||||||||||

Detailed Photos

Our Advantages

We have more than 30years on all kinds of ac motors and gearmotor ,worm reducers producing ,nice price

What we do:

1.Stamping of lamination

2.Rotor die-casting

3.Winding and inserting – both manual and semi-automatically

4.Vacuum varnishing

5.Machining shaft, housing, end shields, etc…

6.Rotor balancing

7.Painting – both wet paint and powder coating

8.assembly

9.Packing

10.Inspecting spare parts every processing

11.100% test after each process and final test before packing.,

FAQ

Q: Do you offer OEM service?

A: Yes

Q: What is your payment term?

A: 30% T/T in advance, 70% balance when receiving B/L copy. Or irrevocable L/C.

Q: What is your lead time?

A: About 30 days after receiving deposit or original L/C.

Q: What certifiicates do you have?

A: We have CE, ISO. And we can apply for specific certificate for different country such as SONCAP for Nigeria, COI for Iran, SASO for Saudi Arabia, etc

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Layout: | Helical |

| Gear Shape: | Helical |

| Step: | Three-Step |

| Samples: |

US$ 224/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Are gear motors suitable for both heavy-duty industrial applications and smaller-scale uses?

Yes, gear motors are suitable for both heavy-duty industrial applications and smaller-scale uses. Their versatility and ability to provide torque multiplication make them valuable in a wide range of applications. Here’s a detailed explanation of why gear motors are suitable for both types of applications:

1. Heavy-Duty Industrial Applications:

Gear motors are commonly used in heavy-duty industrial applications due to their robustness and ability to handle high loads. Here are the reasons why they are suitable for such applications:

- Torque Multiplication: Gear motors are designed to provide high torque output, making them ideal for applications that require substantial force to move or operate heavy machinery, conveyors, or equipment.

- Load Handling: Industrial settings often involve heavy loads and demanding operating conditions. Gear motors, with their ability to handle high loads, are well-suited for tasks such as lifting, pulling, pushing, or driving heavy materials or equipment.

- Durability: Heavy-duty industrial applications require components that can withstand harsh environments, frequent use, and demanding operating conditions. Gear motors are typically constructed with durable materials and designed to withstand heavy vibrations, shock loads, and temperature variations.

- Speed Reduction: Many industrial processes require the reduction of motor speed to achieve the desired output speed. Gear motors offer precise speed reduction capabilities through gear ratios, allowing for optimal control and operation of machinery and equipment.

2. Smaller-Scale Uses:

While gear motors excel in heavy-duty industrial applications, they are also suitable for smaller-scale uses across various industries and applications. Here’s why gear motors are well-suited for smaller-scale uses:

- Compact Size: Gear motors are available in compact sizes, making them suitable for applications with limited space or small-scale machinery, devices, or appliances.

- Torque and Power Control: Even in smaller-scale applications, there may be a need for torque multiplication or precise power control. Gear motors can provide the necessary torque and power output for tasks such as precise positioning, controlling speed, or driving small loads.

- Versatility: Gear motors come in various configurations, such as parallel shaft, planetary, or worm gear designs, offering flexibility to match specific requirements. They can be adapted to different applications, including robotics, medical devices, automotive systems, home automation, and more.

- Efficiency: Gear motors are designed to be efficient, converting the electrical input power into mechanical output power with minimal losses. This efficiency is advantageous for smaller-scale applications where energy conservation and battery life are critical.

Overall, gear motors are highly versatile and suitable for both heavy-duty industrial applications and smaller-scale uses. Their ability to provide torque multiplication, handle high loads, offer precise speed control, and accommodate various sizes and configurations makes them a reliable choice in a wide range of applications. Whether it’s powering large industrial machinery or driving small-scale automation systems, gear motors provide the necessary torque, control, and durability required for efficient operation.

What are some common challenges or issues associated with gear motors, and how can they be addressed?

Gear motors, like any mechanical system, can face certain challenges or issues that may affect their performance, reliability, or longevity. However, many of these challenges can be addressed through proper design, maintenance, and operational practices. Here are some common challenges associated with gear motors and potential solutions:

1. Gear Wear and Failure:

Over time, gears in a gear motor can experience wear, resulting in decreased performance or even failure. The following measures can address this challenge:

- Proper Lubrication: Regular lubrication with the appropriate lubricant can minimize friction and wear between gear teeth. It is essential to follow manufacturer recommendations for lubrication intervals and use high-quality lubricants suitable for the specific gear motor.

- Maintenance and Inspection: Routine maintenance and periodic inspections can help identify early signs of gear wear or damage. Timely replacement of worn gears or components can prevent further damage and ensure the gear motor’s optimal performance.

- Material Selection: Choosing gears made from durable and wear-resistant materials, such as hardened steel or specialized alloys, can increase their lifespan and resistance to wear.

2. Backlash and Inaccuracy:

Backlash, as discussed earlier, can introduce inaccuracies in gear motor systems. The following approaches can help address this issue:

- Anti-Backlash Gears: Using anti-backlash gears, which are designed to minimize or eliminate backlash, can significantly reduce inaccuracies caused by gear play.

- Tight Manufacturing Tolerances: Ensuring precise manufacturing tolerances during gear production helps minimize backlash and improve overall accuracy.

- Backlash Compensation: Implementing control algorithms or mechanisms to compensate for backlash can help mitigate its effects and improve the accuracy of the gear motor.

3. Noise and Vibrations:

Gear motors can generate noise and vibrations during operation, which may be undesirable in certain applications. The following strategies can help mitigate this challenge:

- Noise Dampening: Incorporating noise-dampening features, such as vibration-absorbing materials or isolation mounts, can reduce noise and vibrations transmitted from the gear motor to the surrounding environment.

- Quality Gears and Bearings: Using high-quality gears and bearings can minimize vibrations and noise generation. Precision-machined gears and well-maintained bearings help ensure smooth operation and reduce unwanted noise.

- Proper Alignment: Ensuring accurate alignment of gears, shafts, and other components reduces the likelihood of noise and vibrations caused by misalignment. Regular inspections and adjustments can help maintain optimal alignment.

4. Overheating and Thermal Management:

Heat buildup can be a challenge in gear motors, especially during prolonged or heavy-duty operation. Effective thermal management techniques can address this issue:

- Adequate Ventilation: Providing proper ventilation and airflow around the gear motor helps dissipate heat. This can involve designing cooling fins, incorporating fans or blowers, or ensuring sufficient clearance for air circulation.

- Heat Dissipation Materials: Using heat-dissipating materials, such as aluminum or copper, in motor housings or heat sinks can improve heat dissipation and prevent overheating.

- Monitoring and Control: Implementing temperature sensors and thermal protection mechanisms allows for real-time monitoring of the gear motor’s temperature. If the temperature exceeds safe limits, the motor can be automatically shut down or adjusted to prevent damage.

5. Load Variations and Shock Loads:

Unexpected load variations or shock loads can impact the performance and durability of gear motors. The following measures can help address this challenge:

- Proper Sizing and Selection: Choosing gear motors with appropriate torque and load capacity ratings for the intended application helps ensure they can handle expected load variations and occasional shock loads without exceeding their limits.

- Shock Absorption: Incorporating shock-absorbing mechanisms, such as dampers or resilient couplings, can help mitigate the effects of sudden load changes or impacts on the gear motor.

- Load Monitoring: Implementing load monitoring systems or sensors allows for real-time monitoring of load variations. This information can be used to adjust operation or trigger protective measures when necessary.

By addressing these common challenges associated with gear motors through appropriate design considerations, regular maintenance, and operational practices, it is possible to enhance their performance, reliability, and longevity.

Are there specific considerations for selecting the right gear motor for a particular application?

When selecting a gear motor for a specific application, several considerations need to be taken into account. The choice of the right gear motor is crucial to ensure optimal performance, efficiency, and reliability. Here’s a detailed explanation of the specific considerations for selecting the right gear motor for a particular application:

1. Torque Requirement:

The torque requirement of the application is a critical factor in gear motor selection. Determine the maximum torque that the gear motor needs to deliver to perform the required tasks. Consider both the starting torque (the torque required to initiate motion) and the operating torque (the torque required to sustain motion). Select a gear motor that can provide adequate torque to handle the load requirements of the application. It’s important to account for any potential torque spikes or variations during operation.

2. Speed Requirement:

Consider the desired speed range or specific speed requirements of the application. Determine the rotational speed (in RPM) that the gear motor needs to achieve to meet the application’s performance criteria. Select a gear motor with a suitable gear ratio that can achieve the desired speed at the output shaft. Ensure that the gear motor can maintain the required speed consistently and accurately throughout the operation.

3. Duty Cycle:

Evaluate the duty cycle of the application, which refers to the ratio of operating time to rest or idle time. Consider whether the application requires continuous operation or intermittent operation. Determine the duty cycle’s impact on the gear motor, including factors such as heat generation, cooling requirements, and potential wear and tear. Select a gear motor that is designed to handle the expected duty cycle and ensure long-term reliability and durability.

4. Environmental Factors:

Take into account the environmental conditions in which the gear motor will operate. Consider factors such as temperature extremes, humidity, dust, vibrations, and exposure to chemicals or corrosive substances. Choose a gear motor that is specifically designed to withstand and perform optimally under the anticipated environmental conditions. This may involve selecting gear motors with appropriate sealing, protective coatings, or materials that can resist corrosion and withstand harsh environments.

5. Efficiency and Power Requirements:

Consider the desired efficiency and power consumption of the gear motor. Evaluate the power supply available for the application and select a gear motor that operates within the specified voltage and current ranges. Assess the gear motor’s efficiency to ensure that it maximizes power transmission and minimizes wasted energy. Choosing an efficient gear motor can contribute to cost savings and reduced environmental impact.

6. Physical Constraints:

Assess the physical constraints of the application, including space limitations, mounting options, and integration requirements. Consider the size, dimensions, and weight of the gear motor to ensure it can be accommodated within the available space. Evaluate the mounting options and compatibility with the application’s mechanical structure. Additionally, consider any specific integration requirements, such as shaft dimensions, connectors, or interfaces that need to align with the application’s design.

7. Noise and Vibration:

Depending on the application, noise and vibration levels may be critical factors. Evaluate the acceptable noise and vibration levels for the application’s environment and operation. Choose a gear motor that is designed to minimize noise and vibration, such as those with helical gears or precision engineering. This is particularly important in applications that require quiet operation or where excessive noise and vibration may cause issues or discomfort.

By considering these specific factors when selecting a gear motor for a particular application, you can ensure that the chosen gear motor meets the performance requirements, operates efficiently, and provides reliable and consistent power transmission. It’s important to consult with gear motor manufacturers or experts to determine the most suitable gear motor based on the specific application’s needs.

editor by CX 2024-04-25

China supplier High Torque Reducer Helical Hypoid Gear Reducer Motor Electric Motors with Gearbox with Good quality

Product Description

Product Description

High torque reducer helical hypoid gear reducer motor electric motors with gearbox

1.KM series Helical-hypoid Gearbox’s Characteristics

KM series helical-hypoid gearbox is a new-generation of product developed by Aokman. With a compromise of advanced technology both at home and abroad, its main features are as follows:

(1) Driven by hypoid gears, which has big ratios.

(2) Large output torque, high efficiency, energy saving and environmental protection.

(3) High-quality aluminum alloy housing, and light in weight and non-rusting.

(4) Smooth in running and low in noise, and can work long time in dreadful conditions.

(5) Good-looking in appearance, durable in service life and small in volume.

(6) Suitable for all round installation, wide application and easy use.

(7) The mounting dimension of KM series helical-hypoid gearbox are compatible with RV series worm gearbox.

(8) Modular and multi-structure can meet the demands of various conditions.

Detailed Photos

2. KM series Helical-hypoid Gearbox’s Main Materials

(1) Housing: die-cast aluminum alloy (frame size 27 to 57)

(2) Gear wheel: 20CrMnTiH1 carbonizing & quenching heat treatment make the hardness of gears surface be up to 56-62 HRC, and be retained carburization layers thickness between 0.3 and 0.5mm after precise grinding.

3. KM series Helical-hypoid Gearbox’s Surface Painting

Aluminum alloy housing:

(1) Shot blasting and special antiseptic treatment on the aluminum alloy surface.

(2) After phosphating, spray the RAL9571 silver white paint.4.Gearbox Parameters

Product Parameters

| Models | Stage | Nominal Ratio | Output Speed (n2)* | Max. Torque | Input Shaft Dia. | Output Hole Dia. | Output Shaft Dia. |

| KM050 | 3 Stage | 50~300 | 4.8~27 | 130N.m | Φ11 | Φ20, Φ24 | Φ25 |

| 2 Stage | 7.5~60 | 24~181 | 130N.m | Φ11 | |||

| KM063 | 3 Stage | 50~300 | 4.6~27 | 200N.m | Φ11 | Φ25, Φ28 | Φ25 |

| 2 Stage | 7.5~60 | 23~184 | 200N.m | Φ14 | |||

| KM075 | 3 Stage | 50~300 | 4.7~28 | 350N.m | Φ14 | Φ28, Φ30, Φ35 | Φ28 |

| 2 Stage | 7.5~60 | 24~187 | 350N.m | Φ16 | |||

| KM090 | 3 Stage | 50~300 | 4.7~28 | 500N.m | Φ14 | Φ35, Φ38 | Φ35 |

| 2 Stage | 7.5~60 | 24~187 | 500N.m | Φ19 | |||

| KM110 | 3 Stage | 50~300 | 4.7~27 | 750N.m | Φ19 | Φ40, Φ42 | Φ42 |

| 2 Stage | 7.5~60 | 24~187 | 750N.m | Φ24 |

Packaging & Shipping

Company Profile

Our Advantages

After Sales Service

| Pre-sale services | 1. Select equipment model. |

| 2.Design and manufacture products according to clients’ special requirement. | |

| 3.Train technical personal for clients | |

| Services during selling | 1.Pre-check and accept products ahead of delivery. |

| 2. Help clients to draft solving plans. | |

| After-sale services | 1.Assist clients to prepare for the first construction scheme. |

| 2. Train the first-line operators. | |

| 3.Take initiative to eliminate the trouble rapidly. | |

| 4. Provide technical exchanging. |

FAQ

1.Q:What kinds of gearbox can you produce for us?

A:Main products of our company: UDL series speed variator,RV series worm gear reducer, ATA series shaft mounted gearbox, X,B series gear reducer,

P series planetary gearbox and R, S, K, and F series helical-tooth reducer, more

than 1 hundred models and thousands of specifications

2.Q:Can you make as per custom drawing?

A: Yes, we offer customized service for customers.

3.Q:What is your terms of payment ?

A: 30% Advance payment by T/T after signing the contract.70% before delivery

4.Q:What is your MOQ?

A: 1 Set

If you have any demand for our products please feel free to contact me. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Function: | Speed Changing, Speed Reduction |

| Layout: | Orthogonal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Industry |

| Step: | Double or Three-Step |

| Customization: |

Available

|

|

|---|

Where can individuals find reliable resources for learning more about gear motors and their applications?

Individuals seeking to learn more about gear motors and their applications have access to various reliable resources that provide valuable information and insights. Here are some sources where individuals can find reliable information about gear motors:

1. Manufacturer Websites:

Manufacturer websites are a primary source of information about gear motors. Gear motor manufacturers often provide detailed product specifications, application guides, technical documentation, and educational materials on their websites. These resources offer insights into different gear motor types, features, performance characteristics, and application considerations. Manufacturer websites are a reliable and convenient starting point for learning about gear motors.

2. Industry Associations and Organizations:

Industry associations and organizations related to mechanical engineering, automation, and motion control often have resources and publications dedicated to gear motors. These organizations provide technical articles, whitepapers, industry standards, and guidelines related to gear motor design, selection, and application. Examples of such associations include the American Gear Manufacturers Association (AGMA), International Electrotechnical Commission (IEC), and Institute of Electrical and Electronics Engineers (IEEE).

3. Technical Publications and Journals:

Technical publications and journals focused on engineering, robotics, and motion control are valuable sources of in-depth knowledge about gear motors. Publications like IEEE Transactions on Industrial Electronics, Mechanical Engineering magazine, or Motion System Design magazine often feature articles, case studies, and research papers on gear motor technology, advancements, and applications. These publications provide authoritative and up-to-date information from industry experts and researchers.

4. Online Forums and Communities:

Online forums and communities dedicated to engineering, robotics, and automation can be excellent resources for discussions, insights, and practical experiences related to gear motors. Websites like Stack Exchange, engineering-focused subreddits, or specialized forums provide platforms for individuals to ask questions, share knowledge, and engage in discussions with professionals and enthusiasts in the field. Participating in these communities allows individuals to learn from real-world experiences and gain practical insights.

5. Educational Institutions and Courses:

Technical colleges, universities, and vocational training centers often offer courses or programs in mechanical engineering, mechatronics, or automation that cover gear motor fundamentals and applications. These educational institutions provide comprehensive curricula, textbooks, and lecture materials that can serve as reliable resources for individuals interested in learning about gear motors. Additionally, online learning platforms like Coursera, Udemy, or LinkedIn Learning offer courses on topics related to gear motors and motion control.

6. Trade Shows and Exhibitions:

Attending trade shows, exhibitions, and industry conferences related to automation, robotics, or motion control provides opportunities to learn about the latest advancements in gear motor technology. These events often feature product demonstrations, technical presentations, and expert panels where individuals can interact with gear motor manufacturers, industry experts, and other professionals. It’s a great way to stay updated on the latest trends, innovations, and applications of gear motors.

When seeking reliable resources, it’s important to consider the credibility of the source, the expertise of the authors, and the relevance to the specific area of interest. By leveraging these resources, individuals can gain a comprehensive understanding of gear motors and their applications, from basic principles to advanced topics, enabling them to make informed decisions and effectively utilize gear motors in their projects or applications.

What are some common challenges or issues associated with gear motors, and how can they be addressed?

Gear motors, like any mechanical system, can face certain challenges or issues that may affect their performance, reliability, or longevity. However, many of these challenges can be addressed through proper design, maintenance, and operational practices. Here are some common challenges associated with gear motors and potential solutions:

1. Gear Wear and Failure:

Over time, gears in a gear motor can experience wear, resulting in decreased performance or even failure. The following measures can address this challenge:

- Proper Lubrication: Regular lubrication with the appropriate lubricant can minimize friction and wear between gear teeth. It is essential to follow manufacturer recommendations for lubrication intervals and use high-quality lubricants suitable for the specific gear motor.

- Maintenance and Inspection: Routine maintenance and periodic inspections can help identify early signs of gear wear or damage. Timely replacement of worn gears or components can prevent further damage and ensure the gear motor’s optimal performance.

- Material Selection: Choosing gears made from durable and wear-resistant materials, such as hardened steel or specialized alloys, can increase their lifespan and resistance to wear.

2. Backlash and Inaccuracy:

Backlash, as discussed earlier, can introduce inaccuracies in gear motor systems. The following approaches can help address this issue:

- Anti-Backlash Gears: Using anti-backlash gears, which are designed to minimize or eliminate backlash, can significantly reduce inaccuracies caused by gear play.

- Tight Manufacturing Tolerances: Ensuring precise manufacturing tolerances during gear production helps minimize backlash and improve overall accuracy.

- Backlash Compensation: Implementing control algorithms or mechanisms to compensate for backlash can help mitigate its effects and improve the accuracy of the gear motor.

3. Noise and Vibrations:

Gear motors can generate noise and vibrations during operation, which may be undesirable in certain applications. The following strategies can help mitigate this challenge:

- Noise Dampening: Incorporating noise-dampening features, such as vibration-absorbing materials or isolation mounts, can reduce noise and vibrations transmitted from the gear motor to the surrounding environment.

- Quality Gears and Bearings: Using high-quality gears and bearings can minimize vibrations and noise generation. Precision-machined gears and well-maintained bearings help ensure smooth operation and reduce unwanted noise.

- Proper Alignment: Ensuring accurate alignment of gears, shafts, and other components reduces the likelihood of noise and vibrations caused by misalignment. Regular inspections and adjustments can help maintain optimal alignment.

4. Overheating and Thermal Management:

Heat buildup can be a challenge in gear motors, especially during prolonged or heavy-duty operation. Effective thermal management techniques can address this issue:

- Adequate Ventilation: Providing proper ventilation and airflow around the gear motor helps dissipate heat. This can involve designing cooling fins, incorporating fans or blowers, or ensuring sufficient clearance for air circulation.

- Heat Dissipation Materials: Using heat-dissipating materials, such as aluminum or copper, in motor housings or heat sinks can improve heat dissipation and prevent overheating.

- Monitoring and Control: Implementing temperature sensors and thermal protection mechanisms allows for real-time monitoring of the gear motor’s temperature. If the temperature exceeds safe limits, the motor can be automatically shut down or adjusted to prevent damage.

5. Load Variations and Shock Loads:

Unexpected load variations or shock loads can impact the performance and durability of gear motors. The following measures can help address this challenge:

- Proper Sizing and Selection: Choosing gear motors with appropriate torque and load capacity ratings for the intended application helps ensure they can handle expected load variations and occasional shock loads without exceeding their limits.

- Shock Absorption: Incorporating shock-absorbing mechanisms, such as dampers or resilient couplings, can help mitigate the effects of sudden load changes or impacts on the gear motor.

- Load Monitoring: Implementing load monitoring systems or sensors allows for real-time monitoring of load variations. This information can be used to adjust operation or trigger protective measures when necessary.

By addressing these common challenges associated with gear motors through appropriate design considerations, regular maintenance, and operational practices, it is possible to enhance their performance, reliability, and longevity.

What are the different types of gears used in gear motors, and how do they impact performance?

Various types of gears are used in gear motors, each with its unique characteristics and impact on performance. The choice of gear type depends on the specific requirements of the application, including torque, speed, efficiency, noise level, and space constraints. Here’s a detailed explanation of the different types of gears used in gear motors and their impact on performance:

1. Spur Gears:

Spur gears are the most common type of gears used in gear motors. They have straight teeth that are parallel to the gear’s axis and mesh with another spur gear to transmit power. Spur gears provide high efficiency, reliable operation, and cost-effectiveness. However, they can generate significant noise due to the meshing of teeth, and they may produce axial thrust forces. Spur gears are suitable for applications that require high torque transmission and moderate to high rotational speeds.

2. Helical Gears:

Helical gears have angled teeth that are cut at an angle to the gear’s axis. This helical tooth configuration enables gradual engagement and smoother tooth contact, resulting in reduced noise and vibration compared to spur gears. Helical gears provide higher load-carrying capacity and are suitable for applications that require high torque transmission and moderate to high rotational speeds. They are commonly used in gear motors where low noise operation is desired, such as in automotive applications and industrial machinery.

3. Bevel Gears:

Bevel gears have teeth that are cut on a conical surface. They are used to transmit power between intersecting shafts, usually at right angles. Bevel gears can have straight teeth (straight bevel gears) or curved teeth (spiral bevel gears). These gears provide efficient power transmission and precise motion control in applications where shafts need to change direction. Bevel gears are commonly used in gear motors for applications such as steering systems, machine tools, and printing presses.

4. Worm Gears:

Worm gears consist of a worm (a type of screw) and a mating gear called a worm wheel or worm gear. The worm has a helical thread that meshes with the worm wheel, resulting in a compact and high gear reduction ratio. Worm gears provide high torque transmission, low noise operation, and self-locking properties, which prevent reverse motion. They are commonly used in gear motors for applications that require high gear reduction and locking capabilities, such as in lifting mechanisms, conveyor systems, and machine tools.

5. Planetary Gears:

Planetary gears, also known as epicyclic gears, consist of a central sun gear, multiple planet gears, and an outer ring gear. The planet gears mesh with both the sun gear and the ring gear, creating a compact and efficient gear system. Planetary gears offer high torque transmission, high gear reduction ratios, and excellent load distribution. They are commonly used in gear motors for applications that require high torque and compact size, such as in robotics, automotive transmissions, and industrial machinery.

6. Rack and Pinion:

Rack and pinion gears consist of a linear rack (a straight toothed bar) and a pinion gear (a spur gear with a small diameter). The pinion gear meshes with the rack to convert rotary motion into linear motion or vice versa. Rack and pinion gears provide precise linear motion control and are commonly used in gear motors for applications such as linear actuators, CNC machines, and steering systems.

The choice of gear type in a gear motor depends on factors such as the desired torque, speed, efficiency, noise level, and space constraints. Each type of gear offers specific advantages and impacts the performance of the gear motor differently. By selecting the appropriate gear type, gear motors can be optimized for their intended applications, ensuring efficient and reliable power transmission.

editor by CX 2024-03-04

China Hot selling CHINAMFG Zwbmd003003-625 3mm OEM 1.5V 3V 5V 2.4rpm 50GF. Cm DC Small Planetary Gearbox Gearmotor Micro Reducer Low Rpm Gear Motor vacuum pump oil near me

Product Description

3.4MM DC Planetary Gear Motor

Product Description

above specifications just for reference and customizable according to requirements.

| motor specifications:3mm motor | |

| motors (optional) | stepper motor |

| voltage(optional) | 1.5-5v |

| input speed | <=10000rpm |

| current | 50mA max |

| performance Data:3mm gear stepper motor | ||||||

| Model | Rated speed | max rated torque | Max Instant Torque | Reduction Ratio | gearbox length | Overall Lenth |

| rpm | gf.cm | gf.cm | mm | mm | ||

| ZWBMD003003-5 | 300.0 | 50 | 150 | 5 | 6.0 | 10.75 |

| ZWBMD003003-25 | 60.0 | 50 | 150 | 25 | 7.5 | 12.25 |

| ZWBMD003003-125 | 12.0 | 50 | 150 | 125 | 9.0 | 13.75 |

| ZWBMD003003-625 | 2.4 | 50 | 150 | 625 | 10.5 | 15.25 |

| * The above specifications are subject to change without prior notice. They are for reference only and can be customized as required. | ||||||

Please let us know your requirements and we will provide you with micro transmission solutions.

Product details show:

Application

| Smart wearable devices | watch,VR,AR,XR and etc. |

| Household application | kitchen appliances, sewing machines, corn popper, vacuum cleaner, garden tool, sanitary ware, window curtain, intelligent closestool, sweeping robot, power seat, standing desk, electric sofa, TV, computer, treadmill, spyhole, cooker hood, electric drawer, electric mosquito net, intelligent cupboard, intelligent wardrobe, automatic soap dispenser, UV baby bottle sterilizer, lifting hot pot cookware, dishwasher, washing machine, food breaking machine, dryer, air conditioning, dustbin, coffee machine, whisk,smart lock,bread maker,Window cleaning robot and etc. |

| communication equipment | 5G base station,video conference,mobile phone and etc. |

| Office automation equipments | scanners, printers, multifunction machines copy machines, fax (FAX paper cutter), computer peripheral, bank machine, screen, lifting socket, display,notebook PC and etc. |

| Automotive products | conditioning damper actuator, car DVD,door lock actuator, retractable rearview mirror, meters, optic axis control device, head light beam level adjuster, car water pump, car antenna, lumbar support, EPB, car tail gate electric putter, HUD, head-up display, vehicle sunroof, EPS, AGS, car window, head restraint, E-booster, car seat, vehicle charging station and etc. |

| Toys and models | radio control model, automatic cruise control, ride-on toy, educational robot, programming robot, medical robot, automatic feeder, intelligent building blocks, escort robot and etc. |

| Medical equipments | blood pressure meter, breath machine, medical cleaning pump, medical bed, blood pressure monitors, medical ventilator, surgical staplers, infusion pump, dental instrument, self-clotting cutter, wound cleaning pump for orthopedic surgery,electronic cigarette, eyebrow pencil,fascia gun, , surgical robot,laboratory automation and etc. |

| Industrials | flow control valves, seismic testing,automatic reclosing,Agricultural unmanned aerial vehicle,automatic feeder ,intelligent express cabinet and etc. |

| Electric power tools | electric drill, screwdriver,garden tool and etc. |

| Precision instruments | optics instruments,automatic vending machine, wire-stripping machine and etc. |

| Personal care | tooth brush, hair clipper, electric shaver, massager, vibrator, hair dryer, rubdown machine, scissor hair machine, foot grinder,anti-myopia pen, facial beauty equipment, hair curler,Electric threading knife,POWER PERFECT PORE, Puff machine,eyebrow tweezers and etc. |

| Consumer electronics | camera, mobile phone,digital camera, automatic retracting device,camcorder, kinescope DVD,headphone stereo, cassette tape recorder, bluetooth earbud charging case, turntable, tablet,UAV(unmanned aerial vehicle),surveillance camera,PTZ camera, rotating smart speaker and etc. |

| robots | educational robot, programming robot, medical robot, escort robot and etc. |

Company Profile

HangZhou CHINAMFG Machinery & Electronics Co., Ltd was established in 2001,We provide the total drive solution for customers from design, tooling fabrication, components manufacturing and assembly.

Workshop

Testing Equipment

1) Competitive Advantages

- 1) Competitive Advantages

19+year experience in manufacturing motor gearbox

We provide technical support from r&d, prototype, testing, assembly and serial production , ODM &OEM

Competitive Price

Product Performance: Low noise, High efficiency, Long lifespan

Prompt Delivery: 15 working days after payment

Small Orders Accepted

2) Main Products

-

Precision reduction gearbox and its diameter:3.4mm-38mm,voltage:1.5-24V,power: 0.01-40W,output speed:5-2000rpm and output torque:1.0 gf.cm -50kgf.cm,

- Customized worm and gear transmission machinery;

- Precise electromechanical motion module;

- Precise component and assembly of plastic and metal powder injection.

Our Services

- ODM & OEM

- Gearbox design and development

- Related technology support

- Micro drive gearbox custom solution

Packaging & Shipping

1) Packing Details

packed in nylon firstly, then carton, and then reinforced with wooden case for outer packing.

Or according to client’s requirement.

2) Shipping Details

samples will be shipped within 10 days;

batch order leading time according to the actual situation.

Certifications

Certifications

We Have passed to hold ISO9001:2015(CN11/3571),ISO14001:2004(U006616E0153R3M), ISO13485:2016(CN18/42018) and IATF16949:2016(CN11/3571.01).

and more…

FAQ

FAQ

1. Can you make the gearbox with custom specifications?

YES. We have design and development team, also a great term of engineers, each of them have

many work years experience.

2.Do you provide the samples?

YES. Our company can provide the samples to you, and the delivery time is about 5-15days according to the specification of gearbox you need.

3.What is your MOQ?

Our MOQ is 2000pcs. But at the beginning of our business, we accept small order.

4. Do you have the item in stock?

I am sorry we donot have the item in stock, All products are made with orders.

5. Do you provide technology support?

YES. Our company have design and development team, we can provide technology support if you

need.

6.How to ship to us?

We will ship the goods to you according to the DHL or UPS or FEDEX etc account you provide.

7.How to pay the money?

We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

8. How can I know the product is suitable for me?

Frist, you need to provide us the more details information about the product. We will recommend the item to you according to your requirement of specification. After you confirm, we will prepare the samples to you. also we will offer some good advances according to your product use.

9. Can I come to your company to visit?

YES, you can come to our company to visit at anytime, and welcome to visit our company.

10. How do contact us ?

Please send an inquiry

| Application: | Universal, Industrial, Household Appliances, Car, Power Tools |

|---|---|

| Operating Speed: | Low Speed |

| Excitation Mode: | Permanent Magnet |

| Function: | Control |

| Casing Protection: | Drip-Proof |

| Number of Poles: | 4 |

| Customization: |

Available

|

|

|---|

Can you explain the basic working principle behind a DC motor?

A DC (Direct Current) motor operates based on the fundamental principle of electromagnetic induction. It converts electrical energy into mechanical motion by utilizing the interaction between magnetic fields and current-carrying conductors. Here’s a detailed explanation of the basic working principle behind a DC motor:

1. Construction:

A DC motor consists of several key components:

- Stator: The stator is the stationary part of the motor and typically consists of permanent magnets or electromagnets that produce a fixed magnetic field.

- Rotor: The rotor is the moving part of the motor and is connected to the shaft. It contains coils or windings that carry the armature current.

- Armature: The armature is the core of the rotor that holds the armature windings. The windings are usually made of copper wire and are evenly spaced around the armature.

- Commutator: The commutator is a cylindrical ring attached to the rotor shaft. It consists of multiple segments, usually made of copper, that are insulated from each other.

- Brushes: The brushes are stationary contacts that make physical contact with the commutator segments. They are typically made of carbon or graphite and provide electrical connections to the armature windings.

2. Electromagnetic Induction:

When a current-carrying conductor is placed in a magnetic field, it experiences a force due to the interaction between the magnetic field and the current. This phenomenon is described by the right-hand rule, where the direction of the force is perpendicular to both the current direction and the magnetic field direction.

3. Motor Operation:

When a DC motor is powered, a DC voltage is applied to the armature windings through the brushes and commutator. The current flowing through the armature windings creates a magnetic field around the windings. This magnetic field interacts with the fixed magnetic field produced by the stator, resulting in a force that causes the rotor to rotate.

4. Commutation:

The commutation process is crucial for the continuous rotation of the rotor in a DC motor. As the rotor spins, the brushes make contact with different commutator segments, effectively reversing the direction of the current in the armature windings at the appropriate timing. This reversal of current flow ensures that the torque generated in the armature windings is always in the same direction, allowing for continuous rotation of the rotor.

5. Speed Control:

The speed of a DC motor can be controlled by varying the applied voltage. Reducing the voltage results in a decrease in the magnetic field strength, which in turn decreases the force acting on the armature windings. This reduction in force leads to a decrease in the motor’s speed. Conversely, increasing the voltage increases the speed of the motor. Precise speed control can be achieved by using electronic circuits to regulate the voltage supplied to the motor.

6. Advantages and Applications:

DC motors offer several advantages, including:

- High starting torque, making them suitable for applications requiring high initial force.

- Excellent speed control capabilities, allowing for precise and adjustable speed regulation.

- Relatively simple construction and ease of maintenance.

- Wide range of sizes and power ratings, making them adaptable to various applications.

DC motors find extensive use in numerous applications, such as robotics, industrial automation, electric vehicles, appliances, and more.

By understanding the basic working principle behind a DC motor, one can appreciate its functionality and explore its applications in different fields.

Are there specific types of DC motors designed for different industries or applications?

Yes, there are specific types of DC (Direct Current) motors that are designed and optimized for various industries and applications. DC motors offer a wide range of performance characteristics, allowing them to be tailored to specific requirements. Here’s a detailed explanation of the types of DC motors designed for different industries or applications:

1. Brushed DC Motors:

Brushed DC motors are commonly used in applications that require simple and cost-effective motor solutions. They are suitable for applications with lower efficiency requirements and where maintenance considerations are manageable. Some common industries and applications that use brushed DC motors include:

- Automotive: Power window mechanisms, windshield wipers, cooling fans, and seat adjustment systems.

- Consumer Electronics: Household appliances, toys, power tools, and personal care devices.

- Industrial Machinery: Conveyors, pumps, fans, and machine tools.

2. Brushless DC Motors:

Brushless DC motors are known for their higher efficiency, greater reliability, and precise control capabilities. They are widely used in industries and applications that demand higher performance and advanced control features. Some specific industries and applications that utilize brushless DC motors include:

- Automotive: Electric power steering systems, electric vehicles, hybrid vehicles, and HVAC systems.

- Aerospace and Defense: Actuators, robotics, unmanned aerial vehicles (UAVs), and missile systems.

- Medical and Laboratory Equipment: Centrifuges, pumps, robotics, and diagnostic devices.

- Industrial Automation: CNC machines, robotics, automated guided vehicles (AGVs), and precision motion control systems.

- Renewable Energy: Wind turbine generators, solar tracking systems, and energy storage systems.

3. High-Torque DC Motors:

High-torque DC motors are designed to provide substantial torque output at low speeds. They are commonly used in applications that require heavy lifting or high starting torque. Industries and applications that often utilize high-torque DC motors include:

- Material Handling: Cranes, hoists, winches, lifts, and elevators.

- Construction and Mining: Excavators, bulldozers, drilling rigs, and conveyor systems.

- Automotive: Electric vehicles, electric powertrains, and traction control systems.

- Marine and Shipbuilding: Thrusters, winches, and anchor handling systems.

4. Low-Voltage DC Motors:

Low-voltage DC motors are designed to operate at lower voltages, typically below 24 volts. They are commonly used in battery-powered applications and systems where safety or specific voltage requirements exist. Some industries and applications that utilize low-voltage DC motors include:

- Automotive: Automotive accessories, window actuators, and door locks.

- Robotics and Hobbyist Projects: DIY robots, RC vehicles, and model trains.

- Solar Power Systems: Solar tracking systems, solar panel actuators, and solar-powered water pumps.

- Home Automation: Automated blinds, curtains, and smart home devices.

These are just a few examples of the types of DC motors designed for different industries and applications. The versatility and adaptability of DC motors make them suitable for a wide range of uses, and manufacturers often offer customized motor solutions to meet specific requirements.

How does the size and power rating of a DC motor affect its suitability for different tasks?

The size and power rating of a DC (Direct Current) motor play crucial roles in determining its suitability for different tasks and applications. The size and power rating directly impact the motor’s performance characteristics, including its torque output, speed range, efficiency, and overall capabilities. Here’s a detailed explanation of how the size and power rating of a DC motor affect its suitability for different tasks:

Size of DC Motor:

The size of a DC motor refers to its physical dimensions, including its diameter, length, and overall volume. The size of the motor influences its ability to fit into specific spaces or applications with space constraints. Here are some key considerations regarding the size of a DC motor:

1. Space Limitations: In applications where space is limited, such as small robotic systems or compact machinery, smaller-sized DC motors are preferred. These motors provide a more convenient and efficient integration into the overall system design.

2. Weight Constraints: Certain applications, such as drones or lightweight robots, may have strict weight limitations. Smaller-sized DC motors are generally lighter, making them more suitable for weight-sensitive tasks where minimizing the overall system weight is essential.

3. Cooling and Heat Dissipation: The size of a DC motor can impact its ability to dissipate heat generated during operation. Smaller-sized motors may have less surface area for heat dissipation, which can lead to increased operating temperatures. In contrast, larger-sized motors typically have better heat dissipation capabilities, allowing for sustained operation under heavy loads or in high-temperature environments.

Power Rating of DC Motor:

The power rating of a DC motor refers to the maximum power it can deliver or the power it consumes during operation. The power rating determines the motor’s capacity to perform work and influences its performance characteristics. Here are some key considerations regarding the power rating of a DC motor:

1. Torque Output: The power rating of a DC motor is directly related to its torque output. Higher power-rated motors generally provide higher torque, allowing them to handle more demanding tasks or applications that require greater force or load capacity. For example, heavy-duty industrial machinery or electric vehicles often require DC motors with higher power ratings to generate sufficient torque for their intended tasks.

2. Speed Range: The power rating of a DC motor affects its speed range capabilities. Motors with higher power ratings can typically achieve higher speeds, making them suitable for applications that require rapid or high-speed operation. On the other hand, lower power-rated motors may have limited speed ranges, making them more suitable for applications that require slower or controlled movements.

3. Efficiency: The power rating of a DC motor can impact its efficiency. Higher power-rated motors tend to have better efficiency, meaning they can convert a larger proportion of electrical input power into mechanical output power. Increased efficiency is desirable in applications where energy efficiency or battery life is a critical factor, such as electric vehicles or portable devices.

4. Overload Capability: The power rating of a DC motor determines its ability to handle overloads or sudden changes in load conditions. Motors with higher power ratings generally have a greater overload capacity, allowing them to handle temporary load spikes without stalling or overheating. This characteristic is crucial in applications where intermittent or varying loads are common.

Overall, the size and power rating of a DC motor are important factors in determining its suitability for different tasks. Smaller-sized motors are advantageous in space-constrained or weight-sensitive applications, while larger-sized motors offer better heat dissipation and can handle heavier loads. Higher power-rated motors provide greater torque, speed range, efficiency, and overload capability, making them suitable for more demanding tasks. It is crucial to carefully consider the specific requirements of the application and choose a DC motor size and power rating that aligns with those requirements to ensure optimal performance and reliability.

editor by CX 2023-10-23

China Professional 16mm OEM Electric DC Small Planetary Gearbox Gearmotor Reducer 24V 12 V Low Rpm Gear Motor supplier

Product Description

Product Description

Brushless gear motor , high efficiency and energy saving

Speed reduction ratio is optional

The external scheme can be used in bulk sorting and transportation

The drum motor is customized for the conveying line

With brushless gear motor, 50 kg load can be easily driven

Integrated photoelectric input and output ports, easier field wiring

15 internal rotating speeds and 7 external rotating speeds

Product Parameters

Detailed Photos

FAQ

Q: How to order?

A: send us inquiry → receive our quotation → negotiate details → confirm the sample → sign contract/deposit → mass production → cargo ready → balance/delivery → further cooperation.

Q: How about Sample order?

A: Sample is available for you. please contact us for details. Contact us

Q: Which shipping way is avaliable?

A: DHL, UPS, FedEx, TNT, EMS, China Post,Sea are available.The other shipping ways are also available, please contact us if you need ship by the other shipping way.

Q: How long is the deliver?

A: Devliver time depends on the quantity you order. usually it takes 15-25 working days.

Q: My package has missing products. What can I do?

A: Please contact our support team and we will confirm your order with the package contents.We apologize for any inconveniences.

Q: How to confirm the payment?

A: We accept payment by T/T, PayPal, the other payment ways also could be accepted,Please contact us before you pay by the other payment ways. Also 30-50% deposit is available, the balance money should be paid before shipping.

| Application: | Machine Tool |

|---|---|

| Speed: | 5-1000r/Min |

| Number of Stator: | Single-Phase |

| Function: | Driving |

| Casing Protection: | Totally Enclosed |

| Number of Poles: | 4 |

| Customization: |

Available

| Customized Request |

|---|

What Is a Gear Motor?

A gear motor is an electric motor coupled with a gear train. It uses either DC or AC power to achieve its purpose. The primary benefit of a gear reducer is its ability to multiply torque while maintaining a compact size. The trade-off of this additional torque comes in the form of a reduced output shaft speed and overall efficiency. However, proper gear technology and ratios provide optimum output and speed profiles. This type of motor unlocks the full potential of OEM equipment.

Inertial load

Inertial load on a gear motor is the amount of force a rotating device produces due to its inverse square relationship with its inertia. The greater the inertia, the less torque can be produced by the gear motor. However, if the inertia is too high, it can cause problems with positioning, settling time, and controlling torque and velocity. Gear ratios should be selected for optimal power transfer.

The duration of acceleration and braking time of a gear motor depends on the type of driven load. An inertia load requires longer acceleration time whereas a friction load requires breakaway torque to start the load and maintain it at its desired speed. Too short a time period can cause excessive gear loading and may result in damaged gears. A safe approach is to disconnect the load when power is disconnected to prevent inertia from driving back through the output shaft.

Inertia is a fundamental concept in the design of motors and drive systems. The ratio of mass and inertia of a load to a motor determines how well the motor can control its speed during acceleration or deceleration. The mass moment of inertia, also called rotational inertia, is dependent on the mass, geometry, and center of mass of an object.

Applications

There are many applications of gear motors. They provide a powerful yet efficient means of speed and torque control. They can be either AC or DC, and the two most common motor types are the three-phase asynchronous and the permanent magnet synchronous servomotor. The type of motor used for a given application will determine its cost, reliability, and complexity. Gear motors are typically used in applications where high torque is required and space or power constraints are significant.

There are two types of gear motors. Depending on the ratio, each gear has an output shaft and an input shaft. Gear motors use hydraulic pressure to produce torque. The pressure builds on one side of the motor until it generates enough torque to power a rotating load. This type of motors is not recommended for applications where load reversals occur, as the holding torque will diminish with age and shaft vibration. However, it can be used for precision applications.

The market landscape shows the competitive environment of the gear motor industry. This report also highlights key items, income and value creation by region and country. The report also examines the competitive landscape by region, including the United States, China, India, the GCC, South Africa, Brazil, and the rest of the world. It is important to note that the report contains segment-specific information, so that readers can easily understand the market potential of the geared motors market.

Size

The safety factor, or SF, of a gear motor is an important consideration when selecting one for a particular application. It compensates for the stresses placed on the gearing and enables it to run at maximum efficiency. Manufacturers provide tables detailing typical applications, with multiplication factors for duty. A gear motor with a SF of three or more is suitable for difficult applications, while a gearmotor with a SF of one or two is suitable for relatively easy applications.

The global gear motor market is highly fragmented, with numerous small players catering to various end-use industries. The report identifies various industry trends and provides comprehensive information on the market. It outlines historical data and offers valuable insights on the industry. The report also employs several methodologies and approaches to analyze the market. In addition to providing historical data, it includes detailed information by market segment. In-depth analysis of market segments is provided to help identify which technologies will be most suitable for which applications.

Cost

A gear motor is an electric motor that is paired with a gear train. They are available in AC or DC power systems. Compared to conventional motors, gear reducers can maximize torque while maintaining compact dimensions. But the trade-off is the reduced output shaft speed and overall efficiency. However, when used correctly, a gear motor can produce optimal output and mechanical fit. To understand how a gear motor works, let’s look at two types: right-angle geared motors and inline geared motors. The first two types are usually used in automation equipment and in agricultural and medical applications. The latter type is designed for rugged applications.

In addition to its efficiency, DC gear motors are space-saving and have low energy consumption. They can be used in a number of applications including money counters and printers. Automatic window machines and curtains, glass curtain walls, and banknote vending machines are some of the other major applications of these motors. They can cost up to 10 horsepower, which is a lot for an industrial machine. However, these are not all-out expensive.

Electric gear motors are versatile and widely used. However, they do not work well in applications requiring high shaft speed and torque. Examples of these include conveyor drives, frozen beverage machines, and medical tools. These applications require high shaft speed, so gear motors are not ideal for these applications. However, if noise and other problems are not a concern, a motor-only solution may be the better choice. This way, you can use a single motor for multiple applications.

Maintenance

Geared motors are among the most common equipment used for drive trains. Proper maintenance can prevent damage and maximize their efficiency. A guide to gear motor maintenance is available from WEG. To prevent further damage, follow these maintenance steps:

Regularly check electrical connections. Check for loose connections and torque them to the recommended values. Also, check the contacts and relays to make sure they are not tangled or damaged. Check the environment around the gear motor to prevent dust from clogging the passageway of electric current. A proper maintenance plan will help you identify problems and extend their life. The manual will also tell you about any problems with the gearmotor. However, this is not enough – it is important to check the condition of the gearbox and its parts.

Conduct visual inspection. The purpose of visual inspection is to note any irregularities that may indicate possible problems with the gear motor. A dirty motor may be an indication of a rough environment and a lot of problems. You can also perform a smell test. If you can smell a burned odor coming from the windings, there may be an overheating problem. Overheating can cause the windings to burn and damage.

Reactive maintenance is the most common method of motor maintenance. In this type of maintenance, you only perform repairs if the motor stops working due to a malfunction. Regular inspection is necessary to avoid unexpected motor failures. By using a logbook to document motor operations, you can determine when it is time to replace the gear motor. In contrast to preventive maintenance, reactive maintenance requires no regular tests or services. However, it is recommended to perform inspections every six months.

editor by CX 2023-04-26

China Standard Input speed 1800rpm gearbox reducer nmrv40 reducer zyt series dc motor gear ratio calculator

Error:获取返回内容失败,

Your session has expired. Please reauthenticate.

China supplier High torque small size helical gear speed reducer gearbox with 110V220V single and 3 phases motor hypoid bevel gear

Condition: New

Warranty: 1.5 years

Shape: Cylindrical Gear

Applicable Industries: Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Showroom Location: Egypt

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: New Product 2571

Warranty of core components: 1 Year

Core Components: Engine, Bearing, Gearbox, Motor, Gear

Standard or Nonstandard: Standard

Tooth Profile: HELICAL GEAR

Direction: Right Hand

Material: 20CrMnTi

Processing: Precision Casting

Pressure Angle: 30 Degree

Product Name: Helical gearmotor

Housing: Cast Iron / Aluminum

Gear: 20CrMnTi

Shaft: 40Cr

Gear Precison: DIN 6

Gear Hardness: HRC58~62

Gear Grinding: CNC Reishauer

Bearing: C&U

After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location: Egypt, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, High quality low noise GM37 37mm dc 3v-24v dc gear motor with eccentric 6mm D shaft Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan

Packaging Details: CARTON BOX , PLYWOOD CASES

Port: ZheJiang , high quality roller chain conveyor chain metal chain planetary mixer cyclodial gearbox cyclo gearbox reducer with motor gear HangZhou

Products Description

| Brand | CHBNS |

| Place of origin | ZHangZhouG,CHINA |

| Types | GLW/GHW (Aluminum body) ; GHW/GHF (Cast Iron Body) |

| Model | G18 / G22 / G28 / G32 / G40 / G50 |

| Gear Ratio | 3 ~200 |

| Installation | Foot mounted / Flange mounted |

| Motor power | 0.1~3.7KW (1/8HP -5HP) |

| Motor Type | Single phase / Three Phase |

| Gear Hardness & Precision | HRC58 ~62 (DIN 6) |

| Payment method | L/C ,D/P .T/T .WU ,MONEYGRAM |

| Sea port | ZheJiang ,HangZhou |

| Supply Capacity | 2000 SETS/MONTH |

| Estimated delivery time | Less than 15 days |

| Packing | CARTON BOX , PLYWOOD CASES |

Spiral Gears for Right-Angle Right-Hand Drives

Spiral gears are used in mechanical systems to transmit torque. The bevel gear is a particular type of spiral gear. It is made up of two gears that mesh with one another. Both gears are connected by a bearing. The two gears must be in mesh alignment so that the negative thrust will push them together. If axial play occurs in the bearing, the mesh will have no backlash. Moreover, the design of the spiral gear is based on geometrical tooth forms.

Equations for spiral gear

The theory of divergence requires that the pitch cone radii of the pinion and gear be skewed in different directions. This is done by increasing the slope of the convex surface of the gear’s tooth and decreasing the slope of the concave surface of the pinion’s tooth. The pinion is a ring-shaped wheel with a central bore and a plurality of transverse axes that are offset from the axis of the spiral teeth.

Spiral bevel gears have a helical tooth flank. The spiral is consistent with the cutter curve. The spiral angle b is equal to the pitch cone’s genatrix element. The mean spiral angle bm is the angle between the genatrix element and the tooth flank. The equations in Table 2 are specific for the Spread Blade and Single Side gears from Gleason.

The tooth flank equation of a logarithmic spiral bevel gear is derived using the formation mechanism of the tooth flanks. The tangential contact force and the normal pressure angle of the logarithmic spiral bevel gear were found to be about twenty degrees and 35 degrees respectively. These two types of motion equations were used to solve the problems that arise in determining the transmission stationary. While the theory of logarithmic spiral bevel gear meshing is still in its infancy, it does provide a good starting point for understanding how it works.

This geometry has many different solutions. However, the main two are defined by the root angle of the gear and pinion and the diameter of the spiral gear. The latter is a difficult one to constrain. A 3D sketch of a bevel gear tooth is used as a reference. The radii of the tooth space profile are defined by end point constraints placed on the bottom corners of the tooth space. Then, the radii of the gear tooth are determined by the angle.

The cone distance Am of a spiral gear is also known as the tooth geometry. The cone distance should correlate with the various sections of the cutter path. The cone distance range Am must be able to correlate with the pressure angle of the flanks. The base radii of a bevel gear need not be defined, but this geometry should be considered if the bevel gear does not have a hypoid offset. When developing the tooth geometry of a spiral bevel gear, the first step is to convert the terminology to pinion instead of gear.

The normal system is more convenient for manufacturing helical gears. In addition, the helical gears must be the same helix angle. The opposite hand helical gears must mesh with each other. Likewise, the profile-shifted screw gears need more complex meshing. This gear pair can be manufactured in a similar way to a spur gear. Further, the calculations for the meshing of helical gears are presented in Table 7-1.

Design of spiral bevel gears

A proposed design of spiral bevel gears utilizes a function-to-form mapping method to determine the tooth surface geometry. This solid model is then tested with a surface deviation method to determine whether it is accurate. Compared to other right-angle gear types, spiral bevel gears are more efficient and compact. CZPT Gear Company gears comply with AGMA standards. A higher quality spiral bevel gear set achieves 99% efficiency.

A geometric meshing pair based on geometric elements is proposed and analyzed for spiral bevel gears. This approach can provide high contact strength and is insensitive to shaft angle misalignment. Geometric elements of spiral bevel gears are modeled and discussed. Contact patterns are investigated, as well as the effect of misalignment on the load capacity. In addition, a prototype of the design is fabricated and rolling tests are conducted to verify its accuracy.

The three basic elements of a spiral bevel gear are the pinion-gear pair, the input and output shafts, and the auxiliary flank. The input and output shafts are in torsion, the pinion-gear pair is in torsional rigidity, and the system elasticity is small. These factors make spiral bevel gears ideal for meshing impact. To improve meshing impact, a mathematical model is developed using the tool parameters and initial machine settings.

In recent years, several advances in manufacturing technology have been made to produce high-performance spiral bevel gears. Researchers such as Ding et al. optimized the machine settings and cutter blade profiles to eliminate tooth edge contact, and the result was an accurate and large spiral bevel gear. In fact, this process is still used today for the manufacturing of spiral bevel gears. If you are interested in this technology, you should read on!

The design of spiral bevel gears is complex and intricate, requiring the skills of expert machinists. Spiral bevel gears are the state of the art for transferring power from one system to another. Although spiral bevel gears were once difficult to manufacture, they are now common and widely used in many applications. In fact, spiral bevel gears are the gold standard for right-angle power transfer.While conventional bevel gear machinery can be used to manufacture spiral bevel gears, it is very complex to produce double bevel gears. The double spiral bevel gearset is not machinable with traditional bevel gear machinery. Consequently, novel manufacturing methods have been developed. An additive manufacturing method was used to create a prototype for a double spiral bevel gearset, and the manufacture of a multi-axis CNC machine center will follow.

Spiral bevel gears are critical components of helicopters and aerospace power plants. Their durability, endurance, and meshing performance are crucial for safety. Many researchers have turned to spiral bevel gears to address these issues. One challenge is to reduce noise, improve the transmission efficiency, and increase their endurance. For this reason, spiral bevel gears can be smaller in diameter than straight bevel gears. If you are interested in spiral bevel gears, check out this article.

Limitations to geometrically obtained tooth forms

The geometrically obtained tooth forms of a spiral gear can be calculated from a nonlinear programming problem. The tooth approach Z is the linear displacement error along the contact normal. It can be calculated using the formula given in Eq. (23) with a few additional parameters. However, the result is not accurate for small loads because the signal-to-noise ratio of the strain signal is small.

Geometrically obtained tooth forms can lead to line and point contact tooth forms. However, they have their limits when the tooth bodies invade the geometrically obtained tooth form. This is called interference of tooth profiles. While this limit can be overcome by several other methods, the geometrically obtained tooth forms are limited by the mesh and strength of the teeth. They can only be used when the meshing of the gear is adequate and the relative motion is sufficient.

During the tooth profile measurement, the relative position between the gear and the LTS will constantly change. The sensor mounting surface should be parallel to the rotational axis. The actual orientation of the sensor may differ from this ideal. This may be due to geometrical tolerances of the gear shaft support and the platform. However, this effect is minimal and is not a serious problem. So, it is possible to obtain the geometrically obtained tooth forms of spiral gear without undergoing expensive experimental procedures.

The measurement process of geometrically obtained tooth forms of a spiral gear is based on an ideal involute profile generated from the optical measurements of one end of the gear. This profile is assumed to be almost perfect based on the general orientation of the LTS and the rotation axis. There are small deviations in the pitch and yaw angles. Lower and upper bounds are determined as – 10 and -10 degrees respectively.

The tooth forms of a spiral gear are derived from replacement spur toothing. However, the tooth shape of a spiral gear is still subject to various limitations. In addition to the tooth shape, the pitch diameter also affects the angular backlash. The values of these two parameters vary for each gear in a mesh. They are related by the transmission ratio. Once this is understood, it is possible to create a gear with a corresponding tooth shape.

As the length and transverse base pitch of a spiral gear are the same, the helix angle of each profile is equal. This is crucial for engagement. An imperfect base pitch results in an uneven load sharing between the gear teeth, which leads to higher than nominal loads in some teeth. This leads to amplitude modulated vibrations and noise. In addition, the boundary point of the root fillet and involute could be reduced or eliminate contact before the tip diameter.

China Professional Low Speed Torque Gear Motor 12V with Metal Reducer Gearbox with Best Sales

Product Description

Low Pace Torque Equipment Motor 12v with Metal Reducer Gearbox

Model:D76L(B)-24v95w-20rpm

HangZhou CZPT Science & Technology Co.,Ltd is a subsidiary of HangZhou CZPT Motor Co.,Ltd.The manufacturing facility is positioned in Xihu (West Lake) Dis.,HangZhou,we can design and manufacture of motors in accordance to all our customers’ needs so much,we can manufacture about a hundred,000 motors per thirty day period.

Our major market:

Europe,The us and Asia,including UnitedKingdom,Germany,Italy,France,Sweden, United Condition,Brazil,India,Korea and so on.

Company Rewards:

1. Big generation potential, rapidly supply.

2. Strict QC inspecting policies: all merchandise have to be a hundred% inspected prior to shipping and delivery.

3. OEM/ODM services are obtainable

4. 24 hrs online services.

5. Prompt quotation for your inquiry

6. High quality,dependability and extended solution lifestyle.